2. Install heavy-duty washer and socket

head cap screw, assembled as shown in

sketch titled "Cam Follower Replacement

E-Series Index Drives" in this Service

Manual. Use Red Perma-Lok

®

‚ and

torque the socket head cap screw to

specification. The tightening torque

depends on the size of the cam follower.

See the table titled "Torque Requirements

for Tightening Screws" in this Service

Manual for tightening torque.

3. Install bore plug.

4. Repeat steps to install all cam followers.

5. If a new cam is being installed, install all

but two (2) cam followers. See the sec-

tion titled "Cam and/or input Shaft

Replacement" in this Service Manual.

6. Re-install the socket head cap screws

and follower access cover, using "General

Electric Silicone Rubber RTV-6" or equiv-

alent as a sealant.

7. Re-install the socket head cap screws

and side access cover. This is an exter-

nal cover and sealant is not required.

9

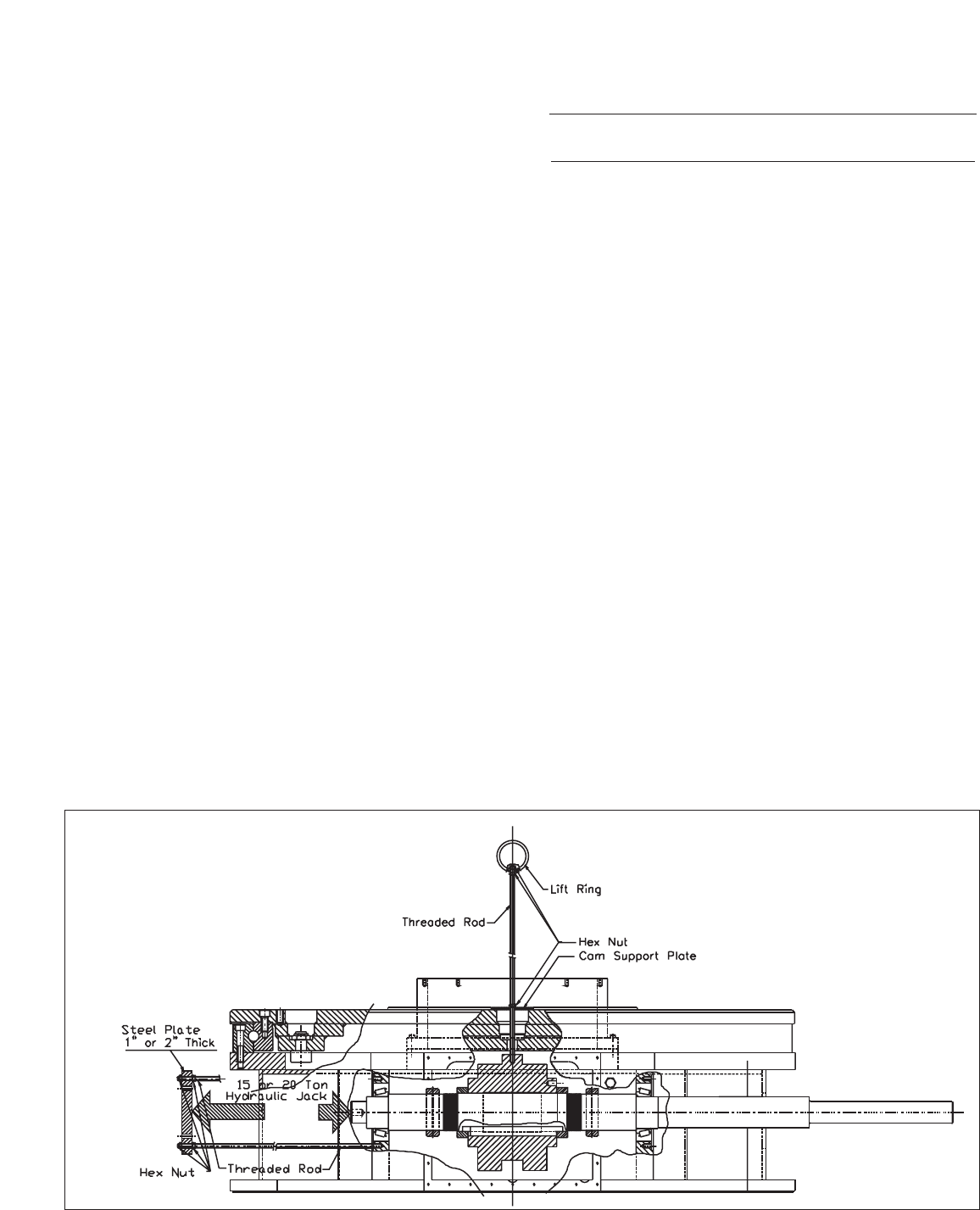

E-SERIES INPUT SHAFT AND CAM REMOVAL

CAM AND/OR INPUT SHAFT

REPLACEMENT:

INPUT SHAFT REMOVAL:

Instructions for removing the cam and input

shaft assume the follower wheel will not be

removed. If the follower wheel will be

removed, proceed to the section titled

"Follower Wheel and/or Output Bearing

Replacement" in this Service Manual.

Otherwise, proceed with the following steps.

If the machine builder has provided access

holes to the cam follower screws, complete

removal of the support structure and fixtures

is not mandatory. The cam can be supported

during removal with a threaded rod through

one of the cam follower stud holes.

Otherwise, the support structure and fixtures

must be removed, or the support structure

and fixtures can be lifted two to three feet

above the unit and supported by appropriate

scaffolding. CAMCO recommends using pro-

fessional machinery riggers for this purpose.

The assistance of a CAMCO trained service-

man is recommended.