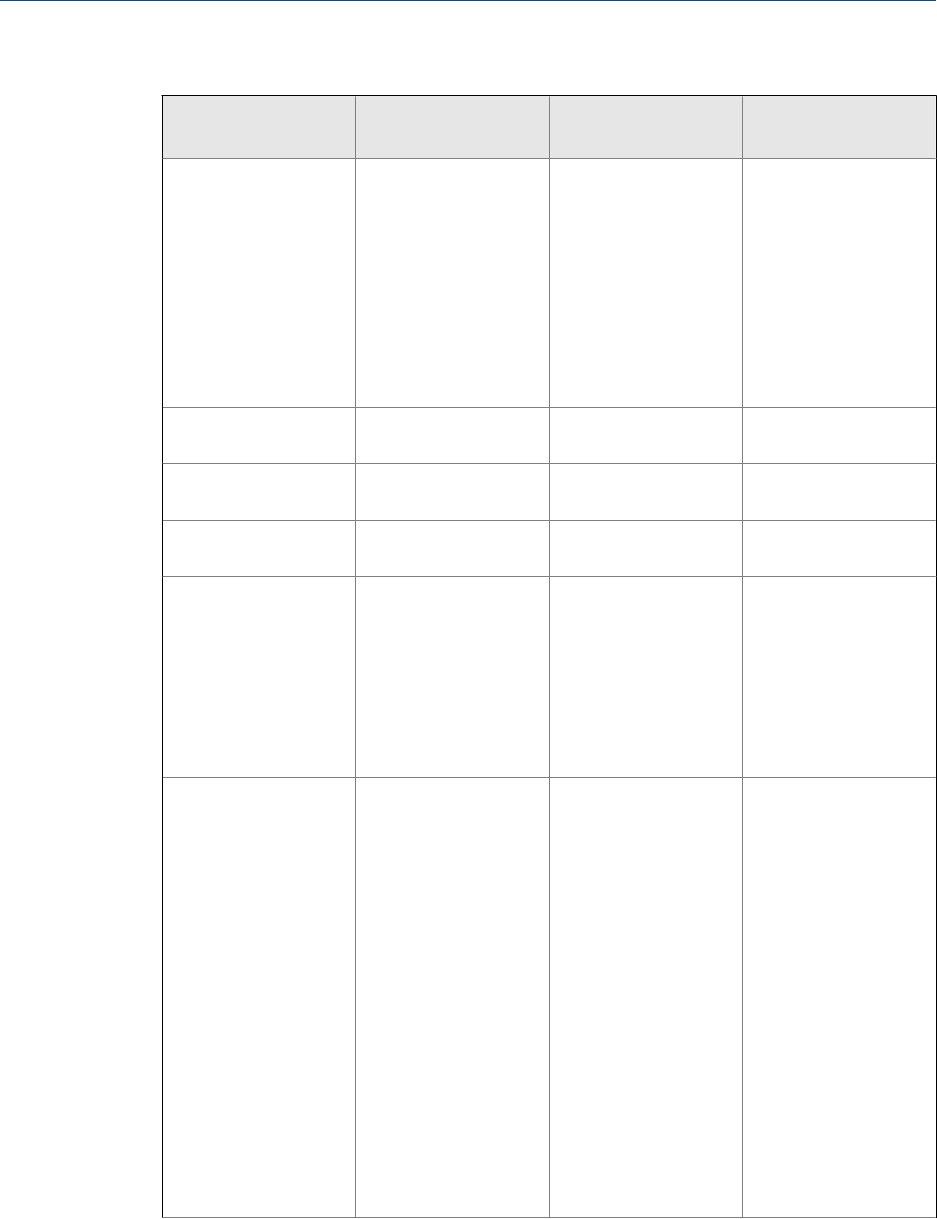

Standard installation types: short-stem metersTable 1-1:

Installation type: Free stream T-Piece

Flow-through

chamber

Meter placement Meter tines are

inserted directly into

the main fluid flow.

The meter must always

be installed

horizontally and with

the tines oriented to

allow flow through or

between the gap of

the tines.

Meter tines are

contained in a side

pocket off the main

flow. The meter must

always be installed

horizontally and with

the tines oriented to

allow flow through or

between the gap of

the tines.

Meter tines are

contained in a flow-

through chamber in

which fluid is

circulated from the

main flow.

Flow rate 0.3 to 0.5 m/s (at the

meter)

0.5 to 3 m/s (at main

pipe wall)

10 to 30 l/min

Viscosity Up to 500 cP Up to 100 cP (250 cP in

some cases)

Up to 500 cP

Temperature –50 °C to 200 °C (–58

°F to 392 °F)

–50 °C to 200 °C (–58

°F to 392 °F)

–50 °C to 200 °C (–58

°F to 392 °F)

Main flow pipe size • Horizontal pipe:

minimum

diameter, 100 mm

(4 inch)

• Vertical pipe:

minimum

diameter, 150 mm

(6 inch)

Minimum diameter,

100 mm (4 inch)

Suitable for all sizes, if

mounted in a bypass

(slipstream)

configuration

Advantages • Simple installation

in large bore pipes

• Ideal for clean

fluids and non-

waxing oils

• Suitable for line

viscosity

measurement and

simple referrals

• Simple installation

in large bore pipes

• Ideal for clean

fluids and non-

waxing oils

• Suitable for line

viscosity

measurement and

simple referrals

• Adaptable

installation to any

diameter main

pipe and for tank

applications

• Ideal for flow and

temperature

conditioning

• Suitable for

complex referrals

and for use with

heat exchangers

• Suitable for step

changes in

viscosity

• Fast response

• Ideal for analyzer

cubicles

Planning

8 Micro Motion Fork Viscosity Meter