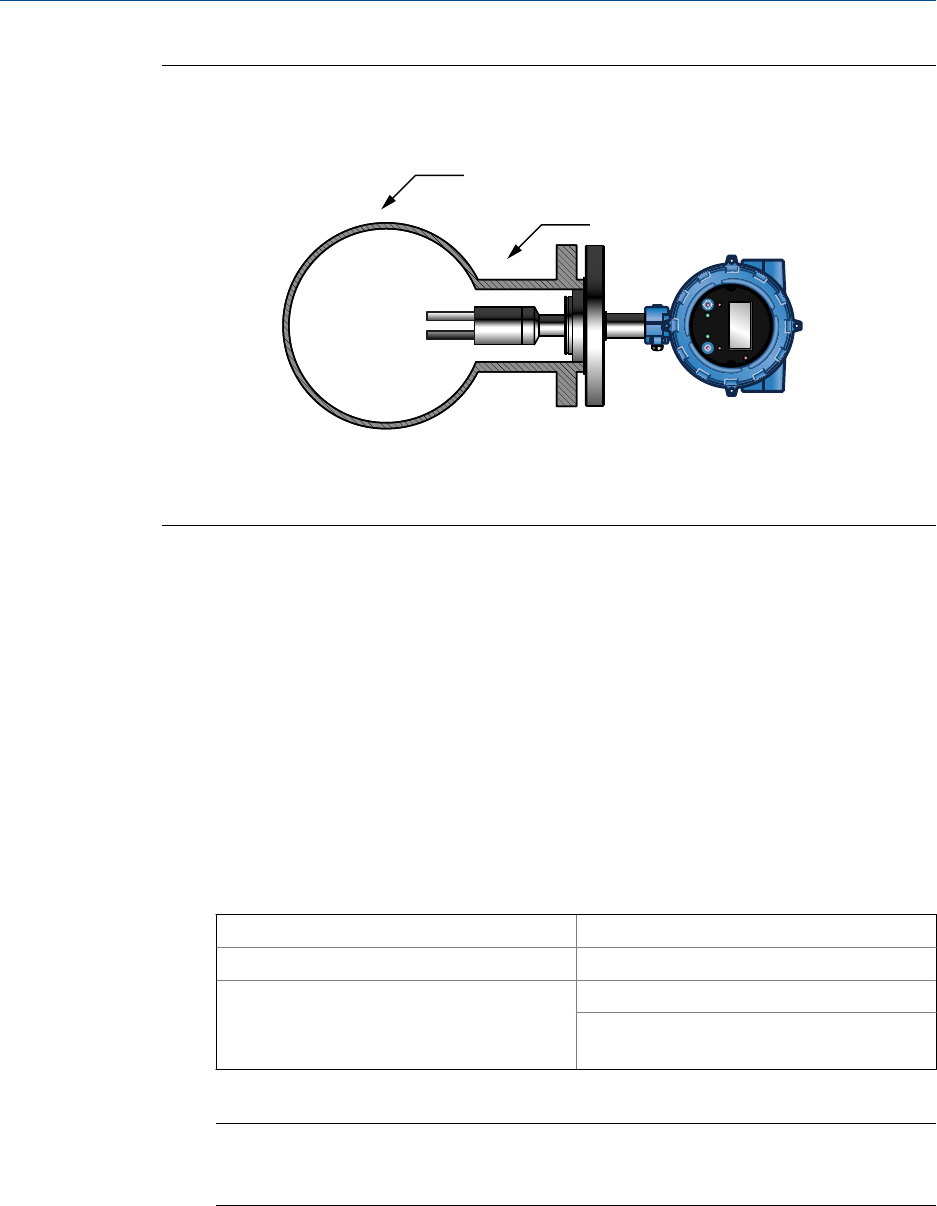

Free-stream (flanged fitting) meter installationFigure 2-1:

B

A

STATUS

SCROLL SELECT

Plan view of a vertical pipe installation

A. 4-inch pipe for horizontal installations; 6-inch (152 mm) pipe for vertical installations

B. Size the recess mount so that the meter tines are inserted fully into the liquid [approximately 2.75 in

(70 mm)].

2.2 Mount in free-stream application (weldolet

fitting)

The weldolet for free-stream installations has a 1.5-inch taper lock fitting and is supplied to

be welded on 4-inch, 6-inch, 8-inch or 10-inch pipelines. A weldolet installation ensures

that the tines of the meter are oriented correctly and are fully inserted into the fluid

stream.

Prerequisites

• Free-stream (weldolet) installations are recommended for processes with the

following conditions:

Flow 0.3 to 0.5 m/s (at the meter)

Viscosity 0.5 to 12,500 cP

Temperature –50 °C to 200 °C (–58 °F to 392 °F)

–40 °C to 200 °C (–40 °F to 392 °F) in

hazardous areas

Note

If temperature variations are a critical factor in your process, the reduced thermal mass of the

taper-lock fitting of the weldolet can track changes in temperature more efficiently.

• Before fitting the weldolet, you must bore a 2.1 in (52.5 mm) diameter opening in

the pipeline to accept the meter. You must weld the weldolet to the pipeline

concentrically with the pre-bored hole.

Mounting

12 Micro Motion Fork Viscosity Meter