3098 Technical Manual Introduction

1-3

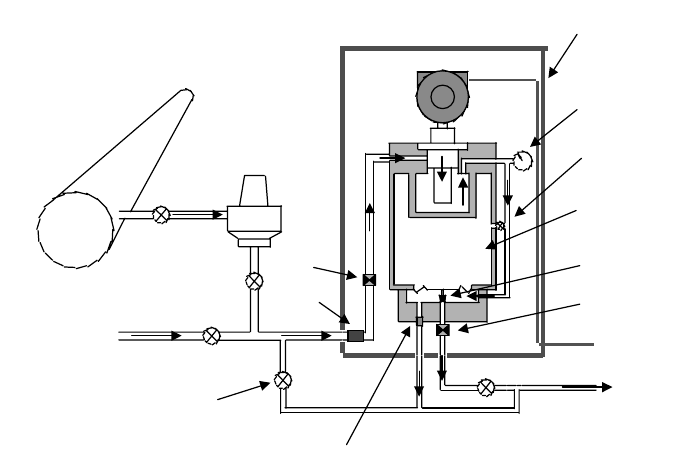

1.2 Functional Description

Gas

Line

ISOLATION

VALVE, D

VALVE A

VALVE B

VENT AND INPUT

FOR CALIBRATION

GASES

VALVE C

DIAPHRAGM

PRESSURE

REGULATOR

FILTER

PRESSURE

RELIEF VALVE

OUTLET

DENSITY

METER

INSULATING

COVER

REFERENCE

CHAMBER

PRESSURE

CONTROL VALVE

CONTROL

PRESSURE

INDICATOR

TO VENT

INPUT

ORIFICE

OUTPUT

ORIFICE

TO SIGNAL

CONVERTER

3098

CHAMBER FILLING

VALVE, E

VALVE F

(PURGING VALVE)

Figure 1-2: Schematic diagram of a typical 3098 Specific Gravity Measuring System

The 3098 Specific Gravity Meter consists of a vibrating cylinder gas density meter surrounded by a gas reference

chamber, which helps to achieve good thermal equilibrium. The gas reference chamber has a fixed volume that is initially

pressurised with the actual line gas. It is then sealed by closing the reference chamber filling valve, thus retaining a fixed

measure and quantity of gas, now known as the reference gas.

Note: Once the chamber has been filled, do not open this valve again.

The sample gas enters the instrument at the enclosure side and passes through a filter, followed by a pressure-reducing

orifice. The sample gas is then fed through input pipework so that it enters the gas density meter at the equilibrium

temperature of the unit. The gas then flows down to a pressure control valve chamber.

The pressure of the reference gas acts on the separator diaphragm and forces the line gas pressure to rise until the

pressures on both sides are equal, thus the gas pressures within the gas density meter and the reference chamber are

equal.

As the ambient temperature changes, the pressure of the fixed volume of reference gas will change as defined by the Gas

Laws. This change in pressure will affect the sample gas pressure within the gas density meter such that the temperature

and pressure changes are self-compensating.

If the sample gas pressure rises above that of the reference chamber pressure, the pressure control valve opens to vent

the excess gas via an outlet orifice in the enclosure side, so that the sample gas pressure is reduced to equal the

reference gas pressure. For gas to flow it is necessary that the supply pressure is greater than the reference pressure,

which in turn must be greater than the vent pressure. (Typically the line pressure must be between 15 and 25% above that

of the reference chamber pressure)

[The principles of operation that describe this operation are given in Appendix B]

A pressure gauge is fitted in order to monitor the pressure within the gas density meter. This is desirable when charging

the reference chamber and also for general maintenance.

Electrical connections to the 3098 are taken through the cable gland in the enclosure side and then into the density

meter’s electronics housing.