4. Install the new motor with the open holes in the

motor mounting plate behind the slots in the

frame and the motor connector facing down, as

shown in Figure 5-5. Reinstall the machine screws

and washers but do not tighten.

5. Raise the motor and work the toothed drive belt

over the outer lip of the hub. Press down gently on

the motor body while rotating the antenna

reflector up and down to ensure free movement.

6. Adjust the belt tension for a maximum of

1

⁄8" (3 mm) deflection with moderate finger

pressure between the hub and gear. Some

readjustment may be necessary if the belt tension

results in excessive antenna reflector vibration.

7. Reconnect the Elevation Motor Molex connector to

the PCB.

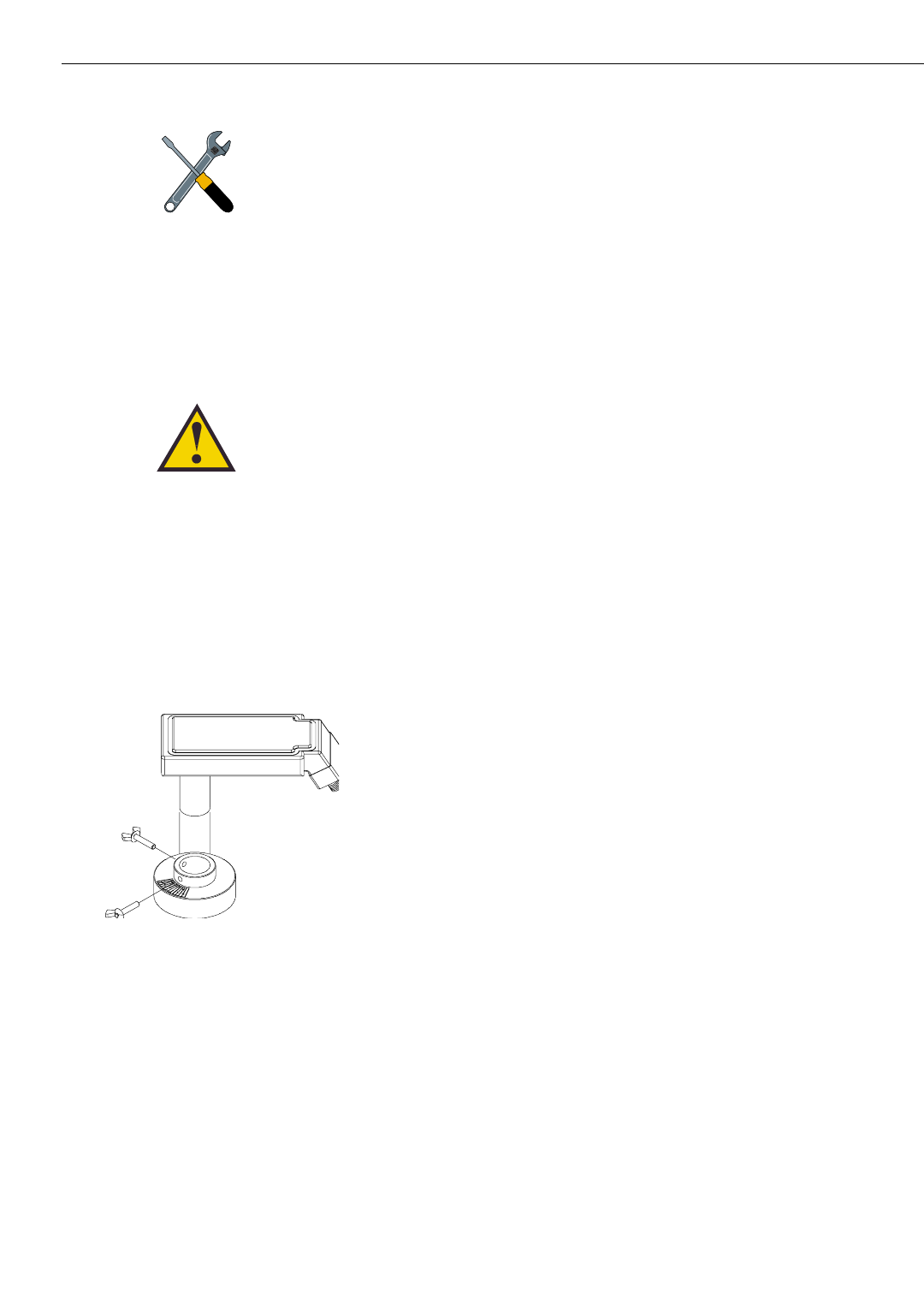

5.7 Antenna LNB Replacement

The LNB assembly receives preamplifier operating power from

the IRD via the RF Detector PCB. Be certain that the IRD is

turned off or disconnected from its power source before

removing or reconnecting the LNB.

1. Disconnect both RF coaxial connectors at the LNB.

Loosen (2) allen set screws on the throat of the

choke feed until the LNB is free to slide out.

Withdraw the LNB.

2. Insert the replacement LNB as far as it will go. Be

sure that it bottoms in the feedhorn. Be careful not

to puncture or dislodge the plastic seal covering

the LNB throat. Orient the LNB to align with the

strut holding the pair of RF cables.

3. Apply a small amount of thread-locking

compound (Loctite 425 or equivalent) to the allen

screw threads and tighten the screws to secure the

LNB in position.

5-10

A Guide to TracVision 4

The short screw must go in the

upper left hole on the motor flange

(as viewed from the motor housing

end with the cable extending

down). Refer to Figure 5-8 for

proper screw location.

Excessive belt tension may result in

antenna reflector vibration.

Figure 5-9

LNB Removal and Alignment