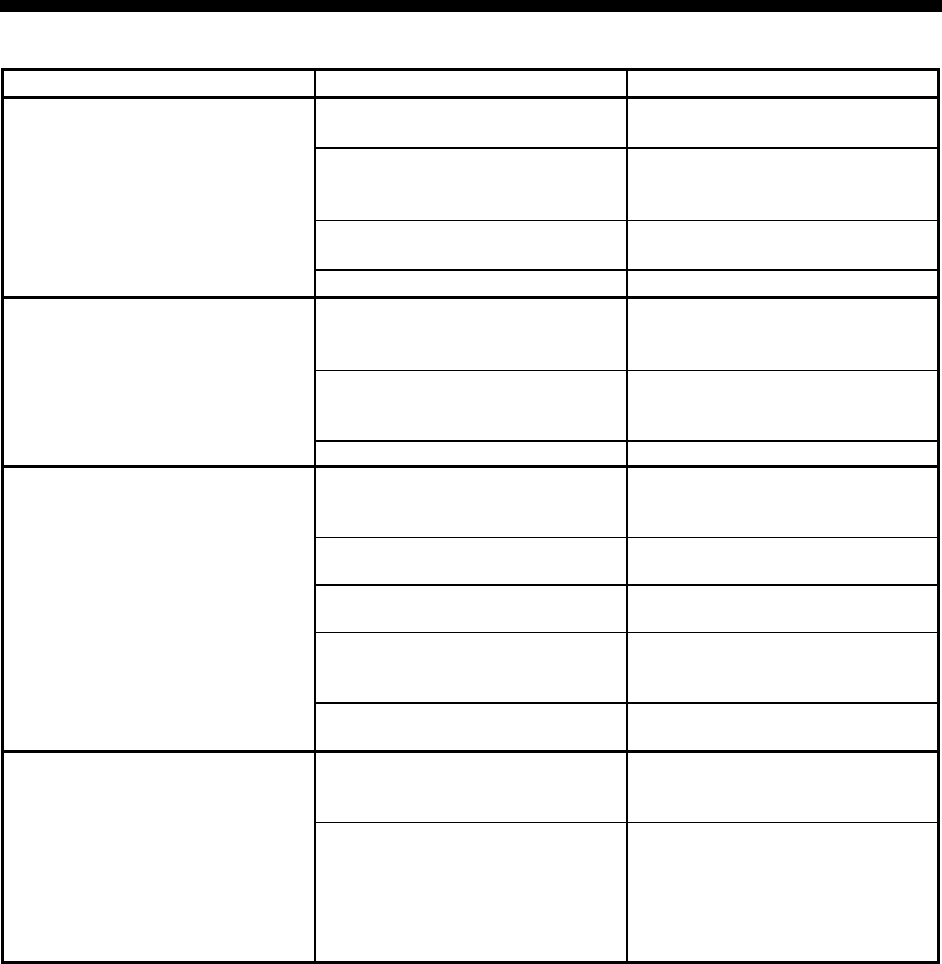

2–Pump 12-Station Controllers Chapter 6: Troubleshooting 46

Chapter 6: Troubleshooting

6-1 General Troubleshooting

Problem Possible cause Solution

The controller panel is not

plugged in.

Plug in the controller panel.

The external disconnect

(recommended) in the dedicated

circuit is open (off).

Close the switch (on).

Fuse/circuit breaker in the power

drop is blown/tripped.

Replace/reset.

The controller panel doesn’t light

up at all.

Broken controller power switch. Replace.

The motor overload has tripped.

Reset the overload and check

the motor for the proper amp

draw on tag.

Main fuse in power drop or

optional fused disconnect has

blown.

Replace the fuse.

A pump package doesn’t run,

even though it is on line and its

indicator is lit.

Motor contact is faulty. Repair or replace as required.

The bin below it is full if its

amber indicator light is off.

Normal operation. When the

level drops, material conveys to

the hopper.

The hopper is off line.

Using the controller, place the

hopper on line.

The convey time for the hopper

is set to zero.

Using the controller, enter a

reasonable convey time.

The field-installed station bypass

switch is simulating a Bin Full

condition.

Normal operation. Set the switch

so the hopper is back in the

loading sequence.

A vacuum hopper is being

bypassed in the loading cycle.

The field-installed station bypass

switch is bad or mis-wired.

Repair, replace, or rewire.

Conveying times are too long

(Time Fill mode only).

Time the hopper(s) during

loading, and set conveying times

to a few seconds less.

Vacuum hoppers are over-filling.

Maximum conveying times are

too long and the PCB does not

recognize the Hopper Full

proximity switch(es).

Check proximity sensors for

proper operation and proper

wiring to the PCB. Repair as

needed. Reset the conveying

times to a reasonable value, and

adjust as needed.