Teledyne API Model 200A NO

X

Analyzer Instruction Manual, 02246, Rev. G, DCN 5247

7.8.5.1 Zero Calibration Procedure

Since the zero gas concentration is defined as 0 ppb, it is not necessary to enter the expected zero

value. The following Table 7-7-14 details the zero calibration procedure.

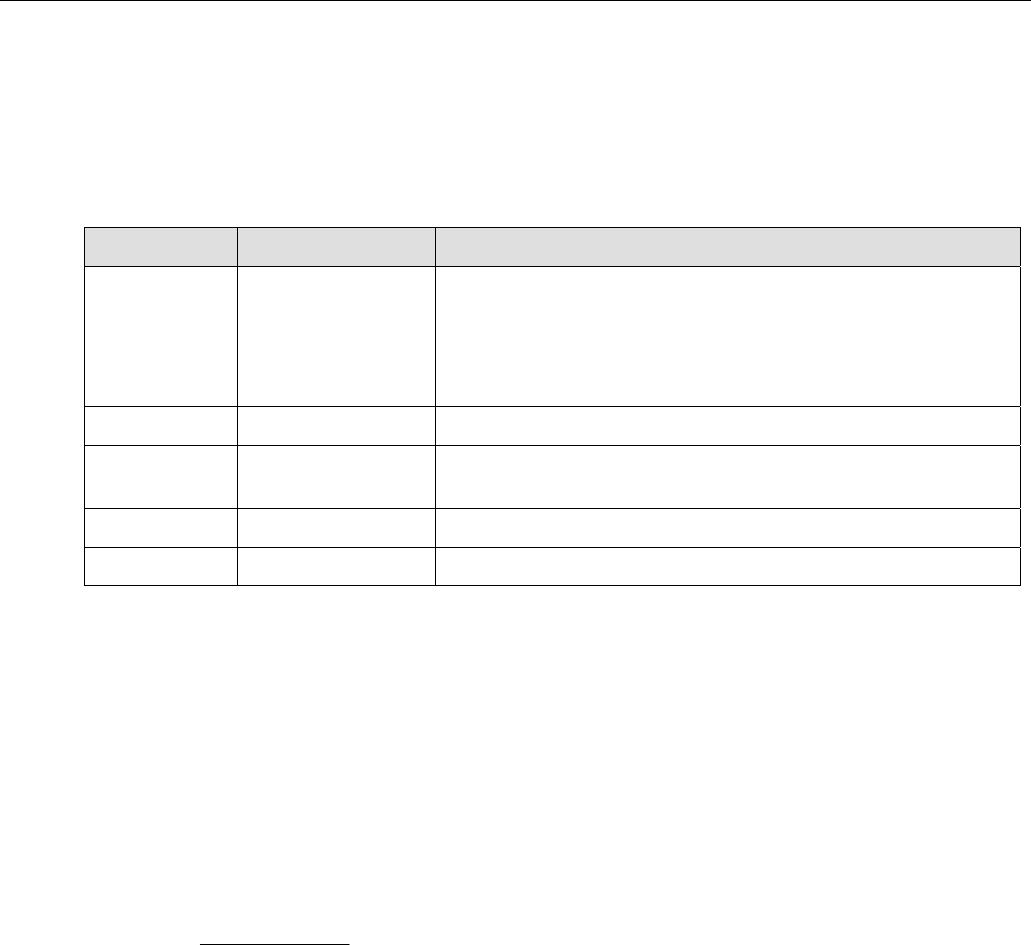

Table 7-7-14: Zero Calibration Procedure

Step Number Action Comment

1. Press CAL The M200A enters the calibrate mode from sample mode.

NOTE:

The analyzer does not operate the zero/span valves in this mode,

the zero gas enters through the sample port.

2. Wait 10 min Wait for reading to stabilize at the zero value.

3. Press ZERO If you change your mind after pressing ZERO, you can still

press EXIT here without zeroing the instrument.

4. Press ENTR Pressing ENTR actually changes the calculation equations.

5. Press EXIT M200A returns to the SAMPLE mode.

7.8.5.2 NO/NO

x

Calibration Procedure

Adjust the NO concentration to approximately 80% of the URL of the NO channel. The expected

NO and NO

x

span concentrations can be determined by measuring the cylinder and diluent flows

and computing the resulting concentrations. If there is any NO

2

impurity in the NO standard gas

it should be taken into account when the NO

x

concentration is entered during the NO/NO

x

channel calibration. This is done by ADDING the impurity concentration to the NO

concentration to get the NO

x

concentration for calibration. Calculate the exact NO and NO

x

concentrations as follows:

F

]

[NO x

F

=

]

[NO

T

STD

NO

OUT

Equation 7-8Enter the respective concentrations using the

procedure in Table 7-13. The expected span concentrations need not be re-entered each time a

calibration is performed unless they are changed.

Enter the expected NO

x

and NO span gas concentrations:

7-22

PRINTED DOCUMENTS ARE UNCONTROLLED