Teledyne API Model 200A NO

X

Analyzer Instruction Manual, 02246, Rev. G, DCN 5247

PSM Diagnostic Procedures

The Linear Power Supply board can be tested by checking the DCPS - TEST function on the

front panel. It should read 2500 mV ± 200 mV. If the value is outside this range, individual

output voltages can be tested on connector P3, see Schematic in the Appendix for pinouts.

The Switching Power Supply output can be tested by observing the temperature of the PMT cold

block using the PMT TEMP - TEST function. The temperature should be constant 7± 2

C. The

output voltage can be observed on J10 of the Switch Board. It should be 15 VDC ± 0.5.

The Switch Board can be tested by observing the diagnostic LEDS along the top edge of the

board. The following Table 9-9-16 describes the typical operation of each LED.

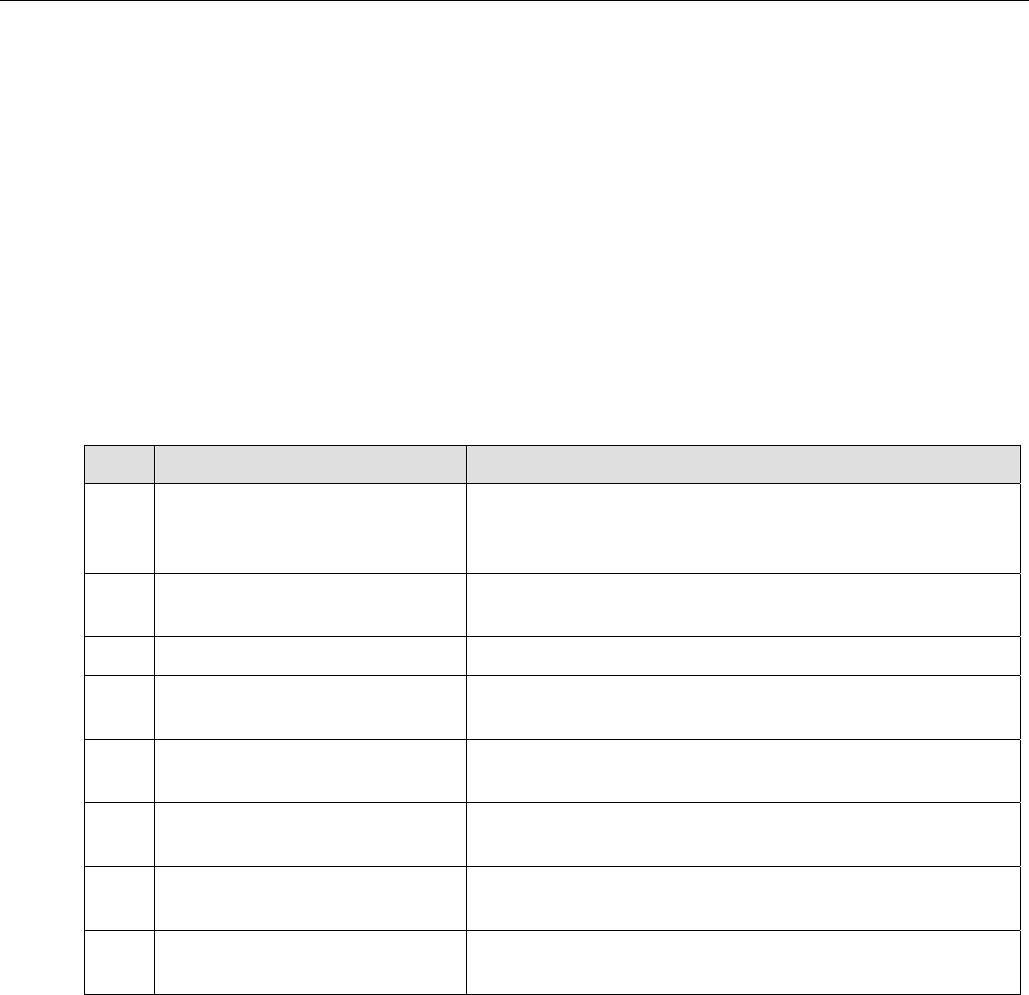

Table 9-9-16: Power Supply Module LED Operation

No. Function Description

1. NO/NO

x

Valve Should switch about every 5 sec.

On(click sound) = NO

x

mode

Off(thud sound) = NO mode

2. Zero/Span Valve Should switch ON when CALZ or CALS button is

pressed.

3. Sample/Cal Valve Should switch ON when CALS button is pressed.

4. AutoZero Valve ON when M200A in AutoZero mode. Happens once

every 6 NO/NO

x

cycles or about once per minute.

5. Ozone Generator Power The ozone generator will be on if it has been more than 30

min since power up.

6. Sample flow control block

heater

Should cycle ON-OFF every 20 sec to 2 min. On

continuously until up to temp.

7. Converter Heater Should cycle ON-OFF every 20 sec to 2 min. On

continuously until up to temp.

8. Reaction Cell Heater Should cycle ON-OFF every 20 sec to 2 min. On

continuously until up to temp.

9-53

PRINTED DOCUMENTS ARE UNCONTROLLED