Integrated Flow Control

68 312779E

Fluid and Air Pressure

Requirements

The fluid input pressure to the fluid regulator must be

high enough to provide a 15-20 psi (0.1-0.14 MPa,

1.0-1.4 bar) pressure differential across the regulator at

the highest flow setting.

For example,

if the maximum

flow rate set point is 280 cc/min and 35 psi outlet pres-

sure is required to achieve that flow, the input pressure

must be 50-55 psi.

Required air pressure to the flow control module is

70-100 psi (0.35-0.7 MPa, 3.5-7.0 bar).

NOTE:

• For flow control modules 249849 and 24H989 used

with a 1:1 fluid regulator, the fluid outlet pressure

from the regulator must be between 12-75 psi

(.08-0.5 MPa, 0.84-5.2 bar) for all flow set points.

Flow rate set points with pressures outside this

range are not achievable. There must be at least 12

psi (.08 MPa, 0.84 bar) fluid pressure at the lowest

flow rate.

• If flow control module 24H989 is used with a fluid

regulator at a ratio greater than 1:1, the relationship

of air pressure to fluid outlet pressure is very impor-

tant. The lowest recommended air pressure from

the V/P is 10-12 psi (.07-.08 MPa, 0.70-0.84 bar).

Back pressure will be required to ensure minimal

fluid pressure at the lowest flow rate setpoint.

The turn down ratio of the typical fluid regulator is

approximately 3:1 or 4:1, depending on material type

and viscosity.

For example,

if the lowest flow rate

required is 100 cc/min, the top flow rate achievable may

be 300-400 cc/min.

NOTE: The top flow rate is not the maximum flow rate

range selected.

Flow Control Operation

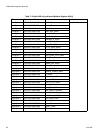

See F

IG

. 73 for module 249849 and F

IG

. 74 for module

24H989. The Flow Control System includes two infor-

mation loops:

•The pressure loop monitors fluid pressure with the

pressure sensor in the module. This allows the sys-

tem to react very quickly to set point changes. The

gun must be triggered during the pressure loop.

•The flow loop monitors fluid flow through flow

meter pulses, ensuring accuracy. The gun must be

triggered during the flow loop.

The Flow Control System creates a data table that tar-

gets a desired flow rate based on the fluid pressure. It

then monitors the flow loop to maintain the flow rate.