6F8A0917

-

154

-

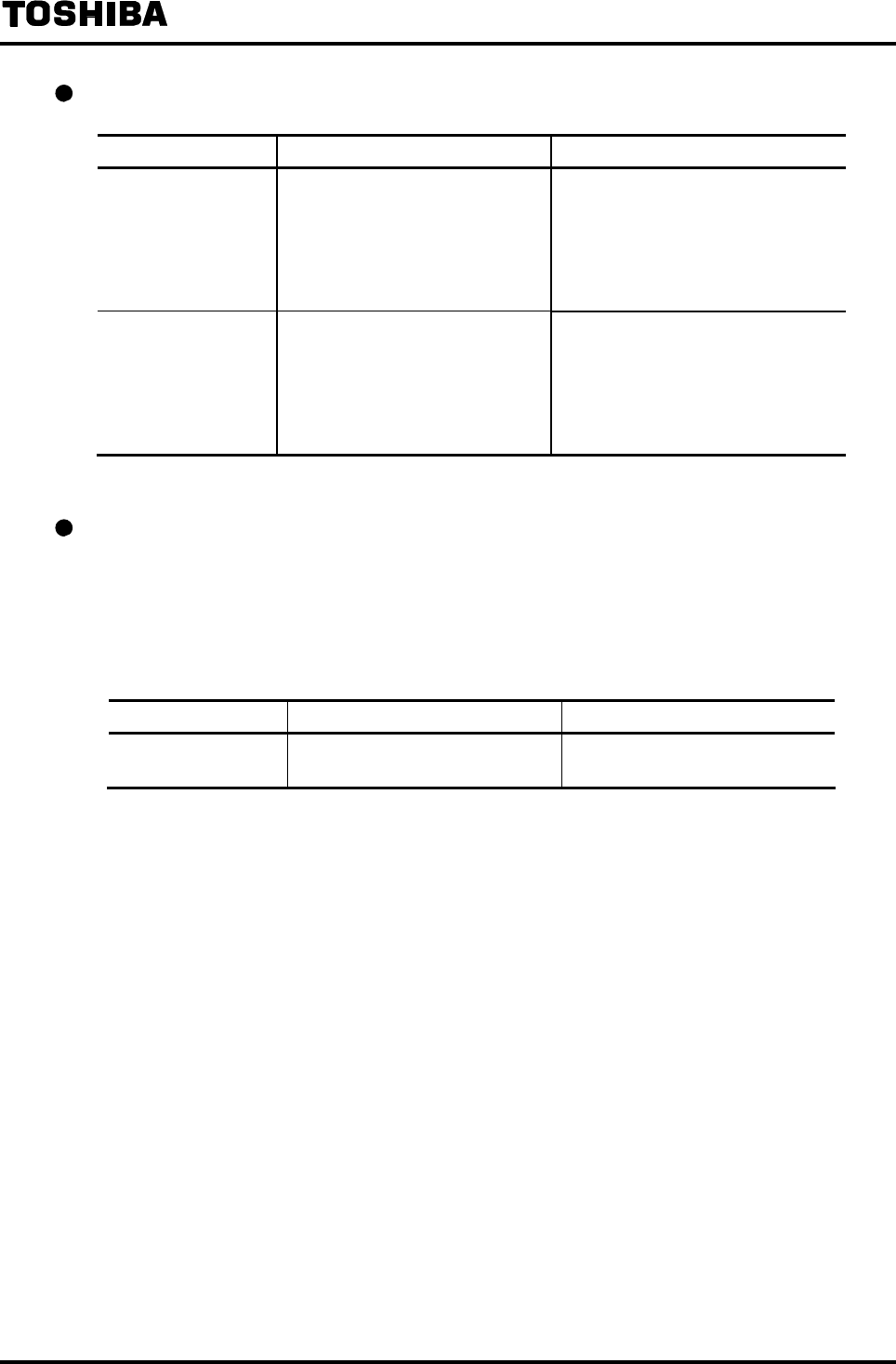

Process error alarm

LCD display Description Corrective action

OVER 125%

The measured value is above the

125% of the span.

The setting range for measured value

is narrow or the flow rate is

unexpectedly large. Check whether

the set value is correct or not and

check that there is no problem in the

process.

UNDER –125%

The measured value is below the

−125% of the span

The setting range of measured value

is narrow or the flow rate is

unexpectedly large. Check whether

the set value is correct or not and

check that there is no problem in the

process.

Fluid empty alarm

Detects that the fluid in the measuring pipe of the detector is empty and an alarm will be displayed.

If the alarm is set to OFF, this function does not work. For how to set this function, see 8.2

“Parameter Check/Change.”

(Note: In the case of LF232*F; Fluid empty alarm function is not usable. Set this function 'OFF'.)

LCD display Description Corrective action

EMPTY

Fluid is not filled in the measuring

pipe of the detector.

Take measures to fill the pipe with

fluid.

Precautionary notes when using the fluid empty alarm

(1) Since the fluid empty alarm is detected using the impedance between the signal wires connected

to a pair of electrodes in the detector as well as the input signal level, a false alarm may be

detected by the following factors:

• Signal wire is broken or loose connection exists

• A large amount of air bubbles are mixed in the fluid

• Insulating materials are accumulated on the electrode

(2) In an environment where grounding is incomplete or excessive noise enters from the outside, the

fluid empty alarm may not work correctly.

In addition, under the condition like this, reliability of flow measurement itself decreases. Take

necessary measures to prevent the entry of noise such as making the ground complete

(independent Class D ground with grounding resistance 100

Ω or less) or reviewing the cable

wiring route.

(3) If the fluid still remains in the measuring pipe or deposits of conductive materials remain in the

measuring pipe, the impedance between the signal wires does not increase and the fluid empty

alarm may not work. In this case, use other method (such as a pump stop signal or a signal from

valves) to check the fluid empty condition.