6-13

Reference

Cleaning Connections for Accurate Measurements

Inspecting Connectors

Because fiber-optic connectors are susceptible to damage that is not immedi-

ately obvious to the naked eye, bad measurements can be made without the

user even being aware of a connector problem. Although microscopic exami-

nation and return loss measurements are the best way to ensure good connec-

tions, they are not always practical. An awareness of potential problems, along

with good cleaning practices, can ensure that optimum connector perfor-

mance is maintained. With glass-to-glass interfaces, it is clear that any degra-

dation of a ferrule or fiber endface, any stray particles, or finger oil on the

endface, can have a significant effect on connector performance. Many times

an instrument must be serviced to replace a damaged connector when thou-

sands of dollars and lost time could have been avoided if better care were

given to the fiber-optic connector.

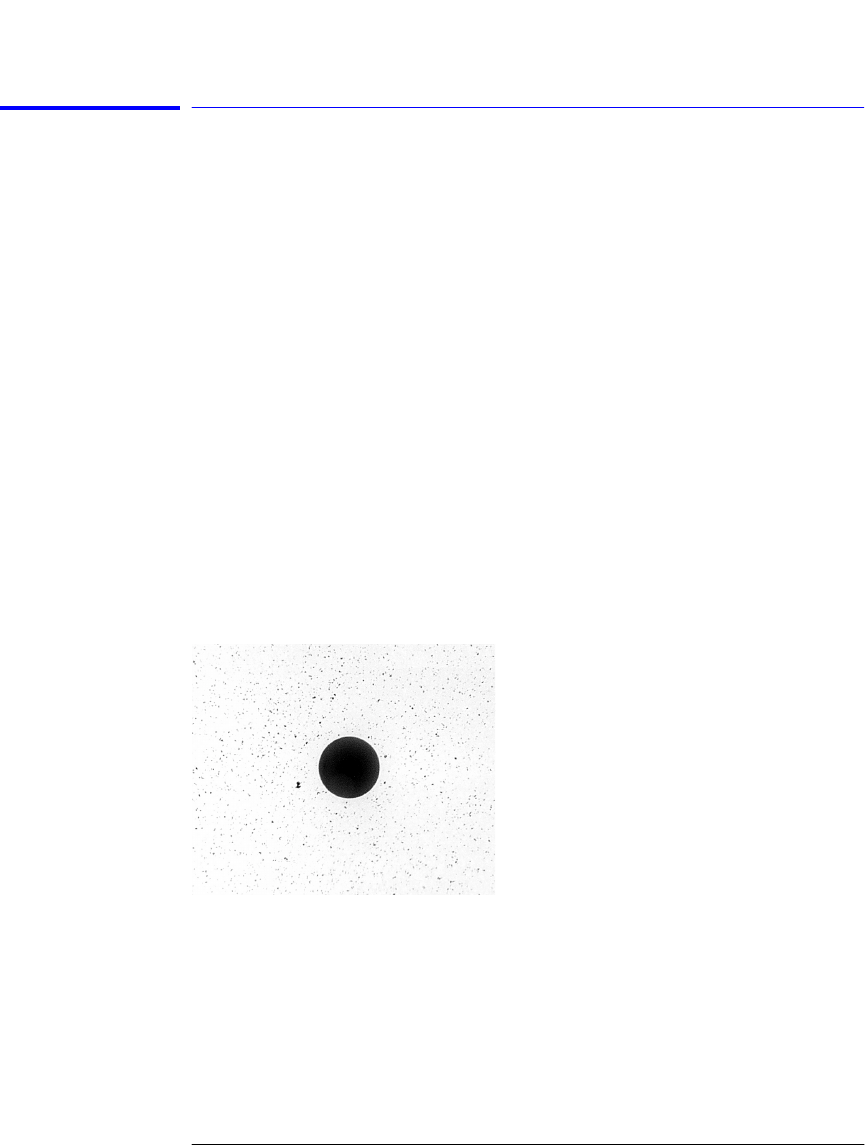

Figure 6-3 is a close-up micrograph of a clean cable endface. In contrast,

Figure 6-4 shows a connector endface that was either not cleaned, or not

properly cleaned. Material is smeared and ground into the endface causing

light scattering and poor reflection. Not only is the precision polish lost, but

this action can grind off the glass face and destroy the connector.

Figure 6-3. A clean and problem-free connector

book.book Page 13 Monday, January 31, 2000 10:34 AM