EXCEL 10 W7761A INPUT/OUTPUT DEVICE

24 74-2699

•

Make earth ground connections with the shortest possible wire run using 14 AWG (2.0 mm

2

) wire. A good earth

ground is essential for W7761A operation. Ideally, connect the earth ground to the ground bus at a motor control

center or circuit breaker panel. However, if the nearest ideal earth ground is inaccessible, consider an alternate

source for earth ground. Metal water pipe is generally a good ground, but do not use sprinkler pipe if prohibited by

local codes. Attention must be given when duct work, conduit, or rebar are to be considered as ground sources. It

is the responsibility of the installer to assure that these structures are tied back to a known earth ground.

Step 4. Prepare Wiring Diagrams

General Considerations

The purpose of this step is to assist the application engineer in developing job drawings to meet job specifications. Wiring

details are included for the W7761A device the T7770A,B,C,D wall module (sensor—current feature that can be used with the

RIO Device) and the T7780 DDWM. The drawings detail I/O, power, and communication bus wiring connections.

NOTE: For field wiring, when two or more wires are to be attached to the same connector block terminal, be sure to twist

them together. Deviation from this rule can result in improper electrical contact. See Fig. 15.

The connector block terminals on the W7761A and on the T7770 accept 14 through 22 AWG (2.0 to 0.34 mm

2

) wire. Table 6

lists wiring types, sizes, and length restrictions for Excel 10 products.

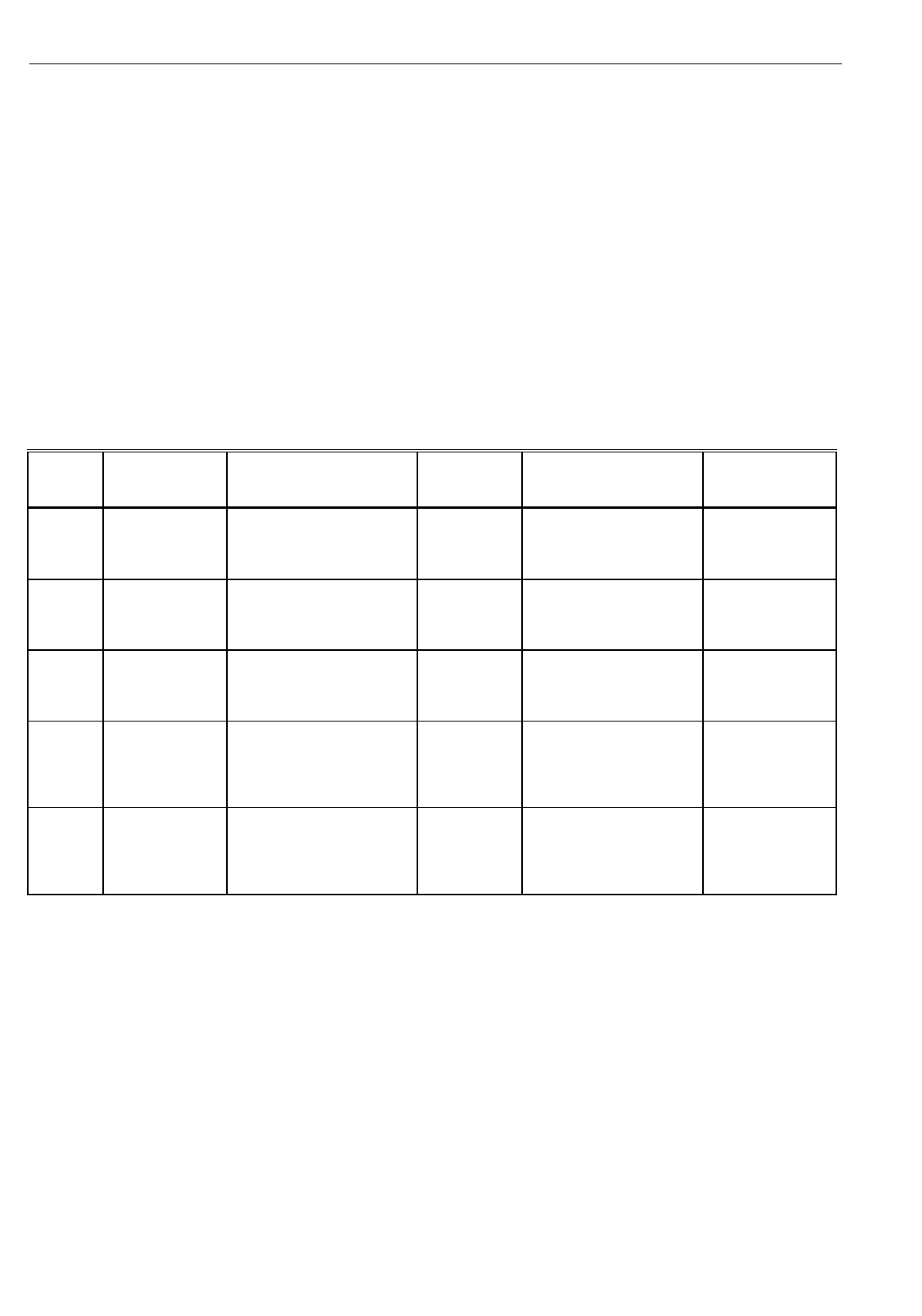

Table 6 . Field Wiring Reference Table.

Wire

Function

Recommended

Minimum Wire

Size AWG (mm

2

) Construction

Specification

or

Requirement Vendor Wire Type

Maximum Length

ft (m)

E-Bus

(Plenum)

22 AWG

(0.34 mm

2

)

Twisted pair solid conductor,

nonshielded or Echelon

approved shielded cable.

Level IV 140°F

(60°C) rating

Honeywell

AK3791 (one twisted pair)

AK3792 (two twisted pairs)

Refer to E-Bus

Wiring Guidelines

for maximum

length

E-Bus

(Non-

Plenum)

22 AWG

(0.34 mm

2

)

Twisted pair solid conductor,

nonshielded or Echelon

approved shielded cable.

Level IV 140°F

(60°C) rating

Honeywell

AK3781 (one twisted pair)

AK3782 (two twisted pairs)

Refer to E-Bus

Wiring Guidelines

for maximum

length

I

nput

Wiring

Sensors

Contacts

18 to 22 AWG

(1.0 to 0.34 mm

2

)

Multiconductor (usually five-

wire cable bundle). For runs

>200 ft (61m) in noisy EMI

areas, use shielded cable.

140°F (60°C)

rating

Standard thermostat wire 1000 ft (305m)

for 18 AWG

200 ft (61m)

for 22 AWG

Output

Wiring

Actuators

Relays

14 AWG (2.0

mm

2

)

(18 AWG (1.0

mm

2

) acceptable

for short runs)

Any pair nonshielded (use

heavier wire for longer

runs).

NEC Class 2

140°F (60°C)

rating

Honeywell

AK3702 (18 AWG)

AK3712 (16 AWG)

AK3754 (14 AWG)

or equivalent

Limited by line-loss

effects on power

consumption.

(See Line Loss

subsection.)

Power

Wiring

14 AWG

(2.0 mm

2

)

Any pair nonshielded (use

heavier wire for longer

runs).

NEC Class 2

140°F (60°C)

rating

Honeywell

AK3754 (14 AWG)

twisted pair

AK3909 (14 AWG) single

conductor or equivalent

Limited by line-loss

effects on power

consumption.

(See Line Loss

subsection.)

W7761A Devices

Fig. 16 through 20 illustrate W7761A Device wiring for various configurations. Connections to the wall module terminals (4

through 6) and the communications terminals (14 and 15) are made at terminal blocks. Connection for access to the E-Bus is

provided by plugging the connector into the communications jack.

NOTE: If an Excel 10 W7761A Device or Zone Manager is not connected to a good earth ground, the device internal transient

protection circuitry is compromised and the function of protecting the device from noise and power line spikes cannot

be fulfilled. This can result in a damaged circuit board and require replacing the device.