Teledyne API Model 100AH SO

2

Analyzer Instruction Manual, 02417, Rev. D

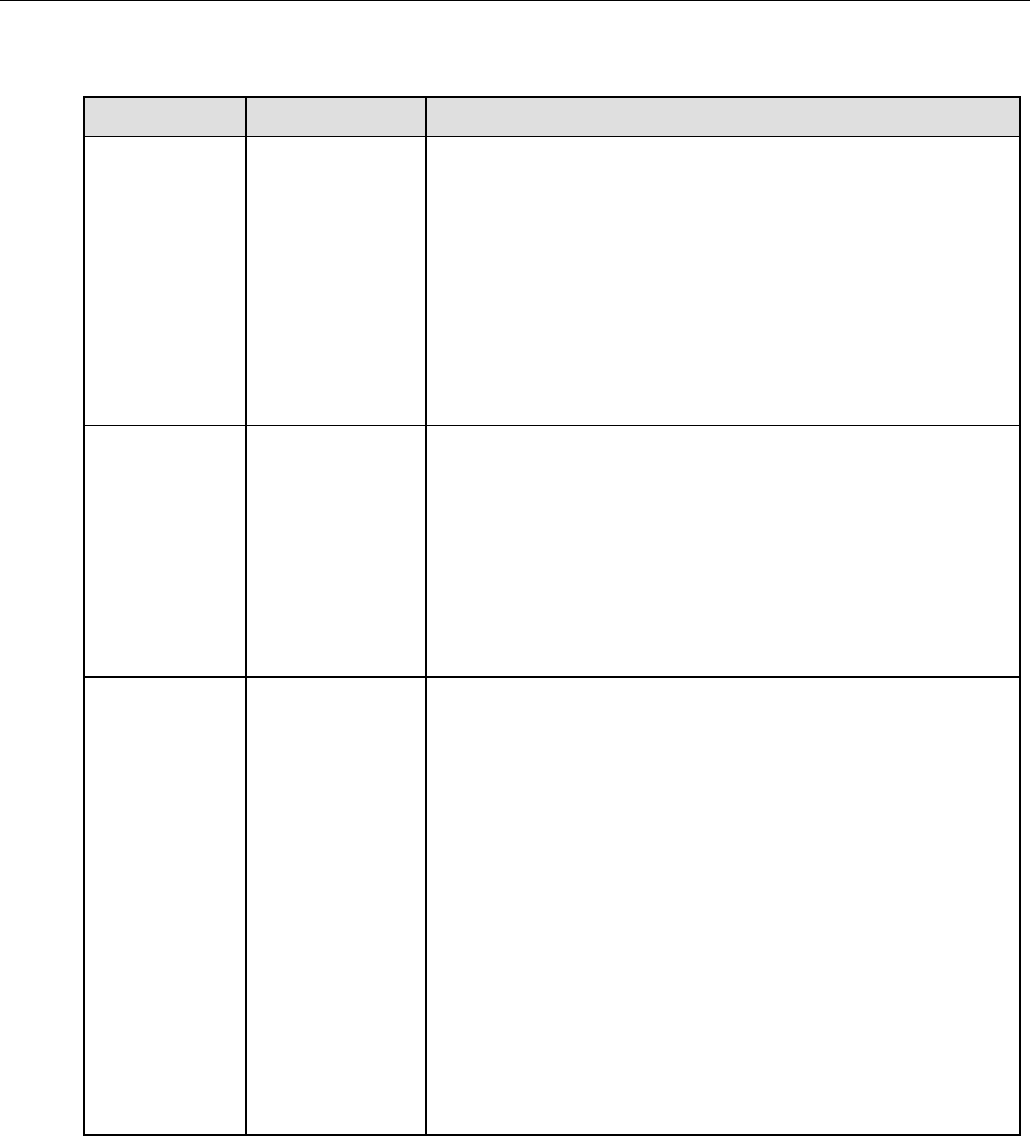

Table 10-1: Test Functions (Continued)

Test Function Factory Set-Up Comment

VACUUM Check value in

Final Test

Values

Table 2-1

Reaction cell pressure is measured to monitor sample pressure

and to compensate any sample pressure variation.

Faults are caused due to:

1. Pump not able to pull the vacuum

2. Faulty pressure sensor

3. Sample line flow restriction

4. Faulty orifice assembly

See Section 10.3.5 Pres/Flow Sensor.

PRES Check value in

Final Test

Values

Table 2-1

Inlet sample pressure is typically 1 In-Hg lower than the

ambient pressure due to the internal pressure drop.

Faults are caused due to:

1. Inlet pressure too high

2. Faulty pressure sensor

3. Sample line flow restriction

See Section 10.3.5 Pres/Flow Sensor.

SAMP FL

650 cc/min

±

65

This is the instrument flow. It is computed value from the

upstream and downstream of the orifice. Incorrect flow can be

caused by the plugged orifice, pneumatic leak, or the flow

meter itself. If the orifice is plugged, computed value could

give a false flow indication.

- A rapid method of determining if the orifice is plugged is to

disconnect the sample inlet from the filter assembly cell, then

briefly put your finger over the fittings on the filter. You

should feel the vacuum build up.

- Another reliable method is to attach a rotameter or soap

bubble flowmeter to the sample filter inlet fitting to measure

the flows.

Flow rate will change

±

a few cc/min due to changes in

sample pressure. Changing altitude changes the ambient air

pressure and therefore the sample flowrate. See

Section 10.2.2 Flow Check.

(table continued)

10-4