M102E/M501 TRS INSTRUMENT MAINTENANCE

(Addendum to M101E Manual - P/N 04740 Rev A)

05514 Rev A1 39

8. INSTRUMENT MAINTENANCE

The following table supercedes Table 9-1 of the M101E Manual - P/N 04740 Rev A

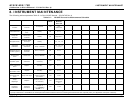

Table 8-1: M102E Preventive Maintenance Schedule

ITEM ACTION FREQUENCY CAL

CHECK

M101E

MANUAL

SECTION

DATE PERFORMED

M501 SO2

scrubber

Replace scrubber

material

As required Yes

8.1.1.3 of

this

addendum

1

Particulate filter

Change particle

filter

Weekly

No

9.3.1

Verify test

functions

Review and

evaluate

Weekly

No Appendix C

Zero/span check

Evaluate offset

and slope

Weekly -- 7.3, 7.6, 7.9

1

Zero/span

calibration

Zero and span

calibration

Every 3 months

--

7.2, 7.4, 7.5,

7.7, 7,8

1

External zero air

scrubber (option)

Exchange

chemical

Every 3 months

No

9.3.4

1

Perform flow

check

Check Flow Every 6 Months No 11.5.2

1

Sample

chamber optics

Clean windows

and filters

Annually or as

necessary

Yes

9.3.6

1

Critical flow

orifice & sintered

filters

Replace

Annually

Yes 9.3.7

Internal IZS

Permeation Tube

Replace Annually YES 9.3.2

Perform

pneumatic leak

check

Verify Leak Tight

Annually or after

repairs involving

pneumatics

Yes

11.5.1

2

Pump

diaphragm

Replace

Every 2 years, or

as necessary

Yes

See

instruction in

diaphragm

kit

PMT sensor

hardware

calibration

Low-level

hardware

calibration

On PMT/ preamp

changes if

0.7 < SLOPE or

SLOPE >1.3

Yes

11.6.3

1

These Items are required to maintain full warranty, all other items are strongly recommended.

2

A pump rebuild kit is available from Teledyne Instruments Customer Service including all instructions and required parts (see Appendix B for part numbers).