TROUBLESHOOTING & REPAIR M102E/M501 TRS

(Addendum to M101E Manual - P/N 04740 Rev A)

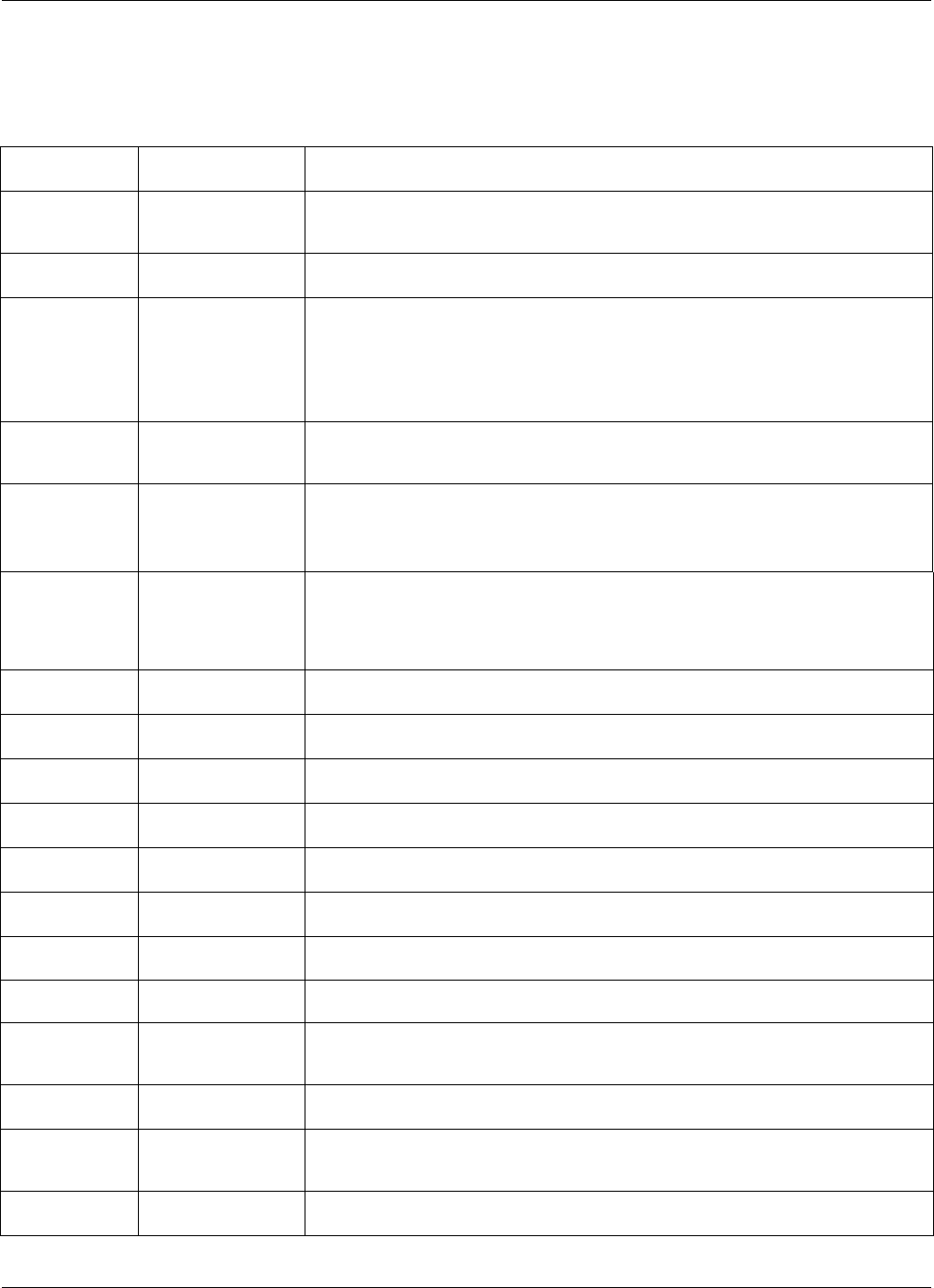

10.1.2. Fault Diagnosis with Test Functions

The Following table supercedes Table 11.2 of the M101E Manual - P/N 04740 Rev A.

Table 10-2: Test Functions - Possible Causes for Out-Of-Range Values

TEST

FUNCTION

NOMINAL

VALUE(S)

POSSIBLE CAUSE(S)

STABIL

≤1 ppb with zero

air

Faults that cause high stability values are: pneumatic leak; low or very unstable

UV lamp output; light leak; faulty HVPS; defective preamp board; aging PMT; PMT

recently exposed to room light; dirty/contaminated reaction cell.

SAMPLE FL

650 cm

3

/min

± 10%

Faults can be caused by: clogged critical flow orifice; pneumatic leak; faulty flow

sensor; sample line flow restriction.

PMT

-20 TO 150 mV

with zero air

High or noisy readings could be due to: calibration error; pneumatic leak; light

leak (improper assembly); aging UV filter; low UV reference output; PMT recently

exposed to room light; light leak in reaction cell; reaction cell contaminated; HVPS

problem.

It takes 24-48 hours for a PMT exposed to ambient light levels to return to normal

functioning.

NORM PMT - -

Noisy Norm PMT value (assuming unchanging SO

2

concentration of sample gas):

Calibration error; HVPS problem; PMT problem; UV reference problem; UV lamp

problem.

UV LAMP 2000 -4000 mV

This is the instantaneous reading of the UV lamp intensity. Low UV lamp intensity

could be due to: aging UV lamp; UV lamp position out of alignment; faulty lamp

transformer; aging or faulty UV detector; dirty optical components.

Intensity lower than 600 mV will cause UV LAMP WARNING.

LAMP RATIO 30 TO 120%

The current output of the UV reference detector divided by the reading stored in

the CPU’s memory from the last time a UV Lamp calibration was performed. Out

of range lamp ratio could be due to: malfunctioning UV lamp; UV lamp position

out of alignment; faulty lamp transformer; aging or faulty UV detector; dirty

optical components; pin holes or scratches in the UV optical filters; light leaks.

STR LGT 40-100 ppb

High stray light could be caused by: aging UV filter; contaminated reaction cell;

light leak; pneumatic leak.

DRK PMT -50 - +200 mV

High dark PMT reading could be due to: light leak; shutter not closing

completely; high pmt temperature; high electronic offset.

DRK LMP -50 - +200 mV

High dark UV detector could be caused by: light leak; shutter not closing

completely; high electronic offset.

HVPS

≈ 400 V to 900 V

Incorrect HVPS reading could be caused by; HVPS broken; preamp board circuit

problems.

RCELL TEMP 50ºC ± 1ºC

Incorrect temperature reading could be caused by: malfunctioning heater; relay

board communication (I

1

C bus); relay burnt out

BOX TEMP

ambient

+ ~ 5ºC

Incorrect temperature reading could be caused by: Environment out of

temperature operating range; broken thermistor; runaway heater

PMT TEMP

7ºC ± 2ºC

constant

Incorrect temperature reading could be caused by: TEC cooling circuit broken;

High chassis temperature; 12V power supply

IZS TEMP

(OPTION)

50ºC ± 1ºC Malfunctioning heater; relay board communication (I

1

C bus); relay burnt out

PRESS

ambient

± 2 IN-HG-A

Incorrect SAMPLE pressure could be due to: pneumatic leak; malfunctioning

valve; malfunctioning pump; clogged flow orifices; sample inlet overpressure;

faulty pressure sensor

SLOPE 1.0 ± 0.3

Slope out of range could be due to: poor calibration quality ; span gas

concentration incorrect; leaks; UV Lamp output decay.

OFFSET < 250 mV

High offset could be due to: incorrect span gas concentration/contaminated zero

air/leak; low-level calibration off; light leak; aging UV filter; contaminated

reaction cell; pneumatic leak.

TIME OF DAY Current time

Incorrect Time could be caused by: Internal clock drifting; move across time

zones; daylight savings time?

52 05514 Rev A1