10 Micro Motion 7829 Viscomaster

®

and Viscomaster Dynamic

™

Viscosity Meters

Installation

2.4 Standard installations

2.4.1 Overview

To overcome the need for in situ calibration for every installation, three standard installations are

proposed. If an installation conforms to one of these standards, the factory calibration of the 7829

Viscomaster

®

/ Viscomaster Dynamic

™

viscosity meter is valid, and in-situ calibration unnecessary.

The three installations are summarized in Table 2-1.

Note: Higher flow rate installations (up to 100 m

3

/hr) can be accommodated. Contact Micro Motion

for details.

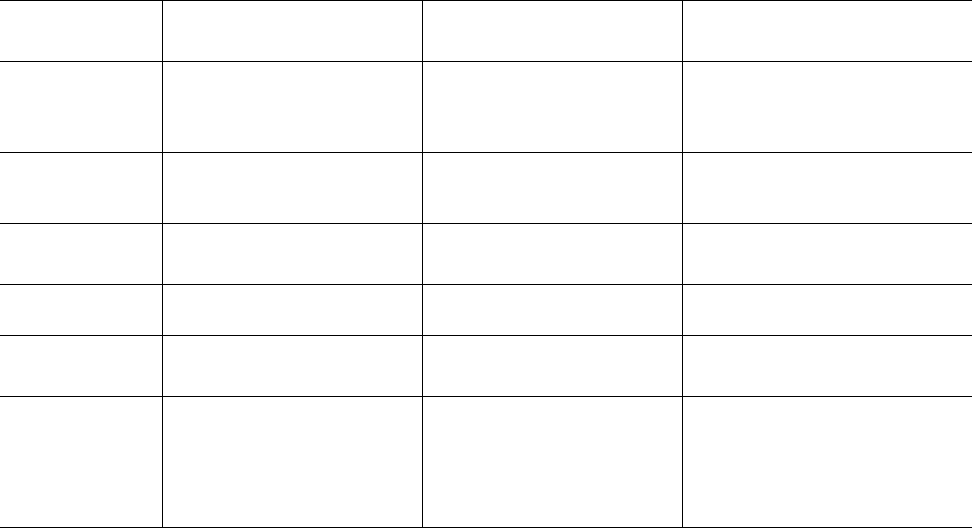

Table 2-1. Descriptions of standard installations

Standard

installation

VAF VISCOTHERM /

NAKAKITA Retrofit

VAF VISCOSENSE Retrofit Flow-through chamber

Description

Viscomaster tines project into

adapter kit with 2½“ Schedule

40 boundary.

Viscomaster tines are

contained in a side pocket off

the main flow, recessed by

25.4 mm (1 inch).

Viscomaster tines are contained in

a flow-through chamber in which

fluid is circulated from the main

flow.

Flow rate

(1)

(1) Viscomaster tines project into adapter kit with 2-½“ Schedule 40 boundary and retracted by 1” (25 mm).

10 to 330 l/min

(0.6 to 20 m

3

/hr)

(2.6 to 87 US gal./min).

10 to 330 l/min

(0.6 to 20 m

3

/hr)

(2.6 to 87 US gal./min).

10 to 330 l/min

(0.6 to 20 m

3

/hr)

(2.6 to 87 US gal./min).

Viscosity

limits

Up to 100 cSt. Up to 100 cSt Up to 100 cSt.

Temperature

-50 to 200°C

(-58 to 392°F).

-50 to 200°C

(-58 to 392°F).

-50 to 200°C

(-58 to 392°F).

Main flow pipe

size

As defined by capillary

Viscomaster chamber.

50 mm (2"). 50 mm (2").

Advantages

• Simple replacement of

capillary viscometer.

• Fast response.

• Good flow and temperature

conditioning.

• Simple replacement of

torsional viscometer.

• Fast response.

• Good flow and temperature

conditioning.

• Adaptable installation to any

diameter main pipe and for tank

applications.

• Ideal for flow and temperature

conditioning.

• Fast response.