54 Micro Motion 7829 Viscomaster

®

and Viscomaster Dynamic

™

Viscosity Meters

General Maintenance

6.2.2 Electrical check

1. Check the power supply and current consumption at the meter terminals, pins 1 and 2, having

disconnected all analog outputs. These should give 35 mA to 42 mA at 22.8 V to 25.2 V.

If the current consumption is outside this range, contact Micro Motion.

6.2.3 Performance check

When several systems are run in parallel and use the same fluid source, comparison of the line

viscosity, base density and temperature readings between installations can be a useful indicator of

possible system faults. Differences between readings, or changes from the normally observed

conditions should always be investigated to confirm that instrumentation is functioning correctly.

6.2.4 Calibration check

1. Carry out a check calibration as detailed in the Calibration Check chapter.

2. Compare the results obtained with the previous calibration figures to identify any substantial

deterioration in meter performance or any malfunction.

Note: A drop in meter performance is likely due to a build up of deposition on the tines which can be

removed by the application of a suitable solvent. See Mechanical Servicing below.

Note: Malfunctions generally could be the result of electrical/electronic faults in either the meter or

the readout equipment. Always check the readout equipment first before attention is directed to the

meter.

6.3 Fault analysis and remedial action

A fault may be categorized as either an erratic reading or a reading which is outside limits.

Electrical faults can also cause symptoms which appear to affect the readings and it is recommended

that the electrical system is checked first, before removing the meter for servicing.

6.3.1 Troubleshooting faults

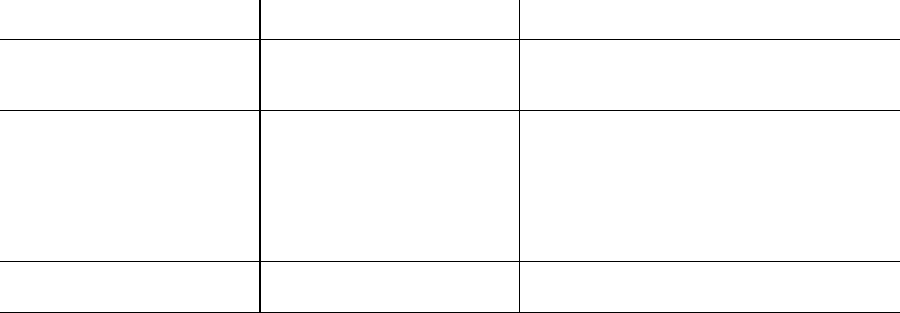

Table 6-1 Faults and possible causes

Fault Possible causes Remedy

Readings fluctuate slightly,

i.e., are noisy

Analog output averaging time

not long enough

Increase the averaging time using ADView’s

Board Configuration facility (see the Using

ADView and ProLink II chapter).

Erratic readings One or more of:

Gas bubbles around tines;

cavitations; severe vibration or

electrical interference; large

amount of contaminants

Remove primary cause; e.g.:

-install air release units to release gas;

-apply back pressure to discourage formation

of bubbles;

-remove cause of vibration

Alternatively, it may be necessary to adjust

the Time Period Trap.

Readings outside limits Deposition and/or corrosion on

the tines.

Clean tines.