Installation and Configuration Manual 13

Installation

Installation Using ADView and ProLink IIElectrical ConnectionsIntroduction

The three compression fittings on the flow pockets (½" drain, ¾" temp probe, and 1-½" mounting nut

for the meter) are rated to above the working pressure of the flow pocket. The fittings may be

Swagelok or Parker; both are used in manufacture.

The fittings are certified to the following standards:

• Swagelok: SO9001 / 9002, ASME,TUV,CSA,DNV

• Parker: ISO 9001 / 9002, TUV, DNV, LLOYDS

2.4.4 VAF Viscosense retrofit

Conditions:

• Temperature: -50 to +200 °C (–58 °F to 392 °F)

• Flow: 40 to 330 l/min (2.5 to 20 m

3

/hr) (11 to 87 US gal/min)

• Viscosity limit: Up to 100 cSt

• Pressure: As defined by process flanges

• Calibration boundary: 2-½” Schedule 40

This retro-fit kit has been specifically designed to provide a simple, direct replacement for existing

vibration-type viscometers. Typically, the flange-to-flange distance is 5.9” (150 mm), although other

larger versions can be accommodated (contact Micro Motion for details of the Universal retro-fit

adapter). Usually, no pipework changes are necessary.

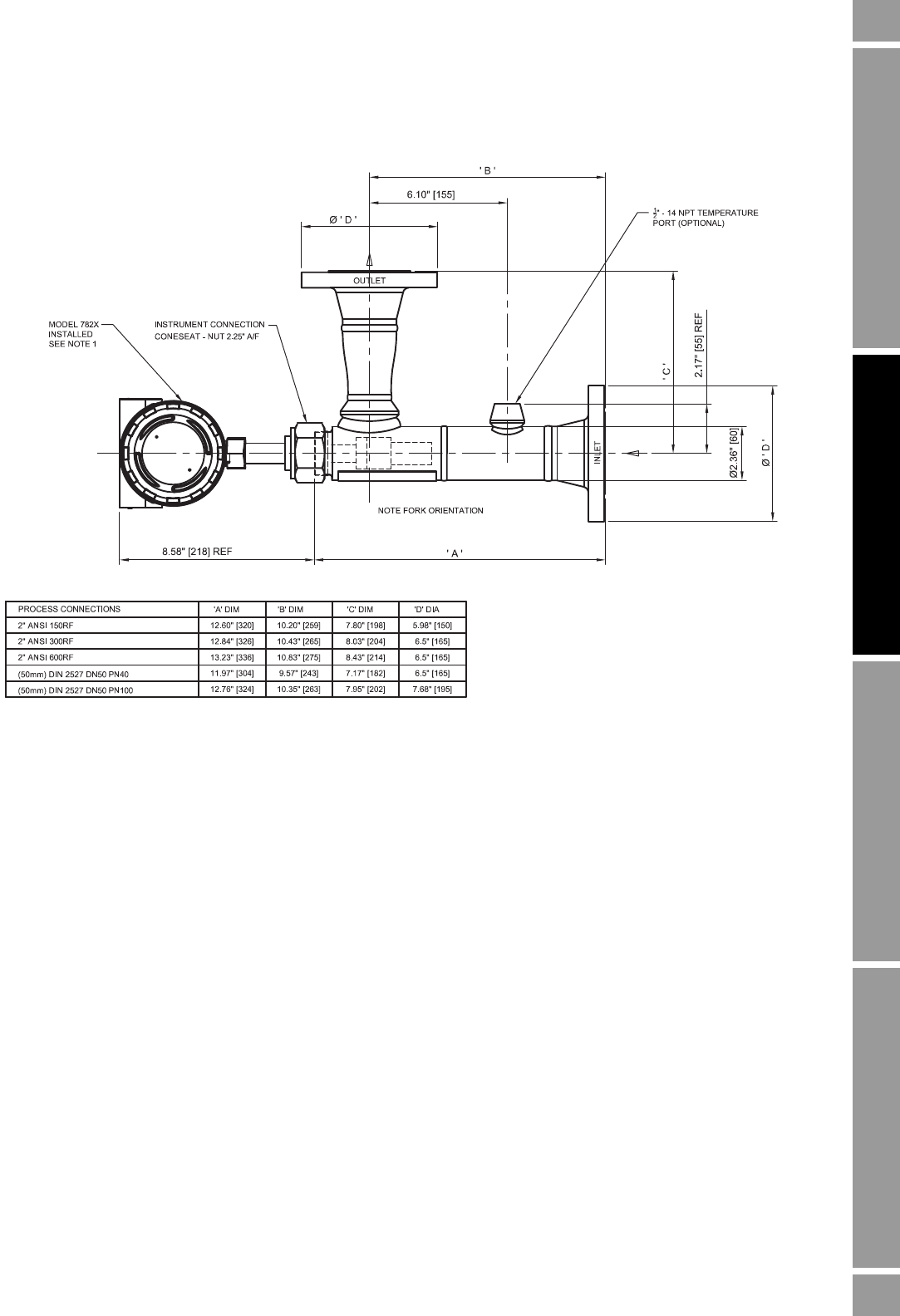

Dimensions shown in inches (mm)