Installation and Configuration Manual 25

Electrical Connections

Installation Using ADView and ProLink IIElectrical ConnectionsIntroduction Installation Using ADView and ProLink IIElectrical ConnectionsIntroduction Installation Using ADView and ProLink IIElectrical ConnectionsIntroduction Installation Using ADView and ProLink IIElectrical ConnectionsIntroduction

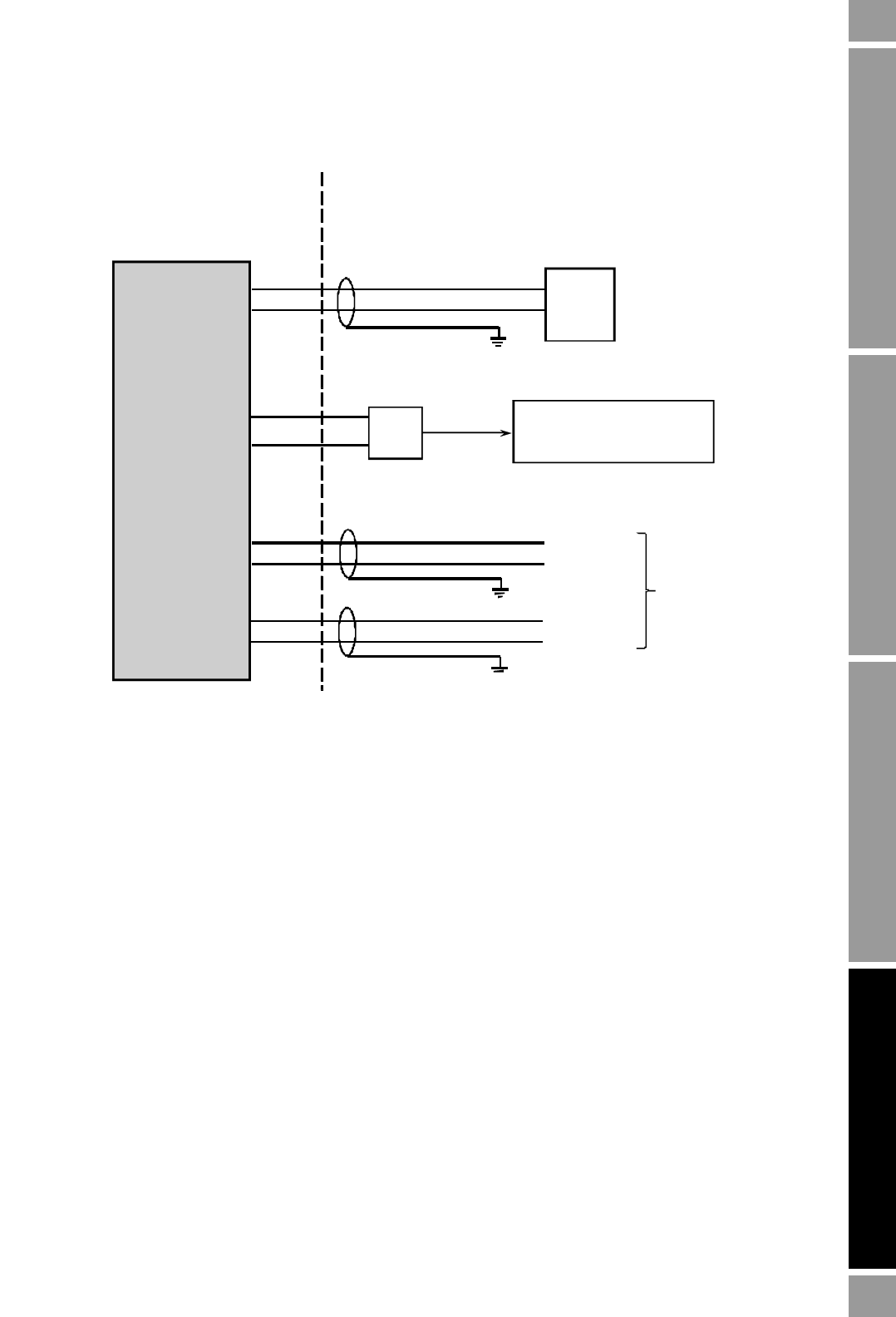

Figure 3-1 Wiring diagram

Notes

1. The main 24 VDC power supply must supply the following: 20 to 28 VDC at 50 mA for

transmitter; and, 22 mA per analog output used.

2. The RS-485/232 converter and PC are not normally installed permanently. However it is

strongly recommended that the wiring to the meter is made at installation.

3. Upon leaving factory, the two analog outputs are non-isolated as they are powered through

internal links to Power Supply Input.

4. If split-pads “LNK A” (Analog Output 1) and “LNK B” (Analog Output 2) by the terminal

block are broken, the two 4-20 mA analog outputs become isolated; direct connections to an

external power supply is then required. A second or third external 20 to 28 VDC power supply

can be used. (See 4-20 mA outputs section for more details).

5. Typically, four pairs of shielded 19/0.30 mm

2

(#16 AWG) to 19/0.15 mm

2

(#22 AWG) wires

are used for wiring.

6. The naming conventions for RS-485 signals differ between manufacturers. If RS-485

communications do not function correctly, try swapping the ‘A’ and ‘B’ signals over at one end

of the link.

HAZARDOUS AREA SAFE AREA

Viscosity meter

Power +

Power -

RS-485 A

RS-485 B

4-20 mA output 1 +

4-20 mA output 1 -

Power supply

(

20...28 Vdc at 50 mA)

+ 24V

0V

RS-485/232

converter

To RS-232 port on a PC running

ADView or ProLink II (v2.9 or later)

software for monitoring,

maintenance and configuration.

Analog o/p +

Analog o/p -

1

2

4

3

5

6

4-20 mA output 2 +

4-20 mA output 2 -

Analog o/p -

7

8

Analog o/p +

Passive outputs

(see the 4-20 mA

outputs section for

more information)