5. Build the viscosity matrix.

a. In the first column, enter the temperatures for which you will enter viscosity

data.

b. In the second column, enter the viscosity of the first process fluid, at each of the

specified temperatures.

Enter viscosity in either cP or cSt, depending on the setting of Matrix Data Unit.

c. In the third column, enter the viscosity of the second process fluid at each of the

specified temperatures.

d. Continue until you have entered and sent data for all process fluids at all

temperatures.

Important

• You must enter the temperature values in order, either low-to-high or high-to-low.

• You must enter the process fluids in order of viscosity, either low-to-high or high-to-low.

• The matrix must be 2×2 or larger.

6. Click Apply.

The transmitter processes the matrix data and determines if it can be used for

measurement.

7. Check the values displayed for Fit Results and Fit Accuracy.

Fit Results can be Good, Poor, or Empty. Good means that the matrix is mathematically

capable of generating data. Poor means that the matrix cannot generate data. If Fit

Results = Poor, adjust the matrix and try again. If Fit Results = Empty, ensure that you

have entered data for all temperature–viscosity pairs and that the data meets the

requirements listed above.

Fit Accuracy is the maximum difference between the referred viscosity value

calculated by the meter and the referred viscosity value that is expected at each of

the temperature–viscosity pairs.

8. Choose the method to be used to supply temperature data, and perform the

required setup.

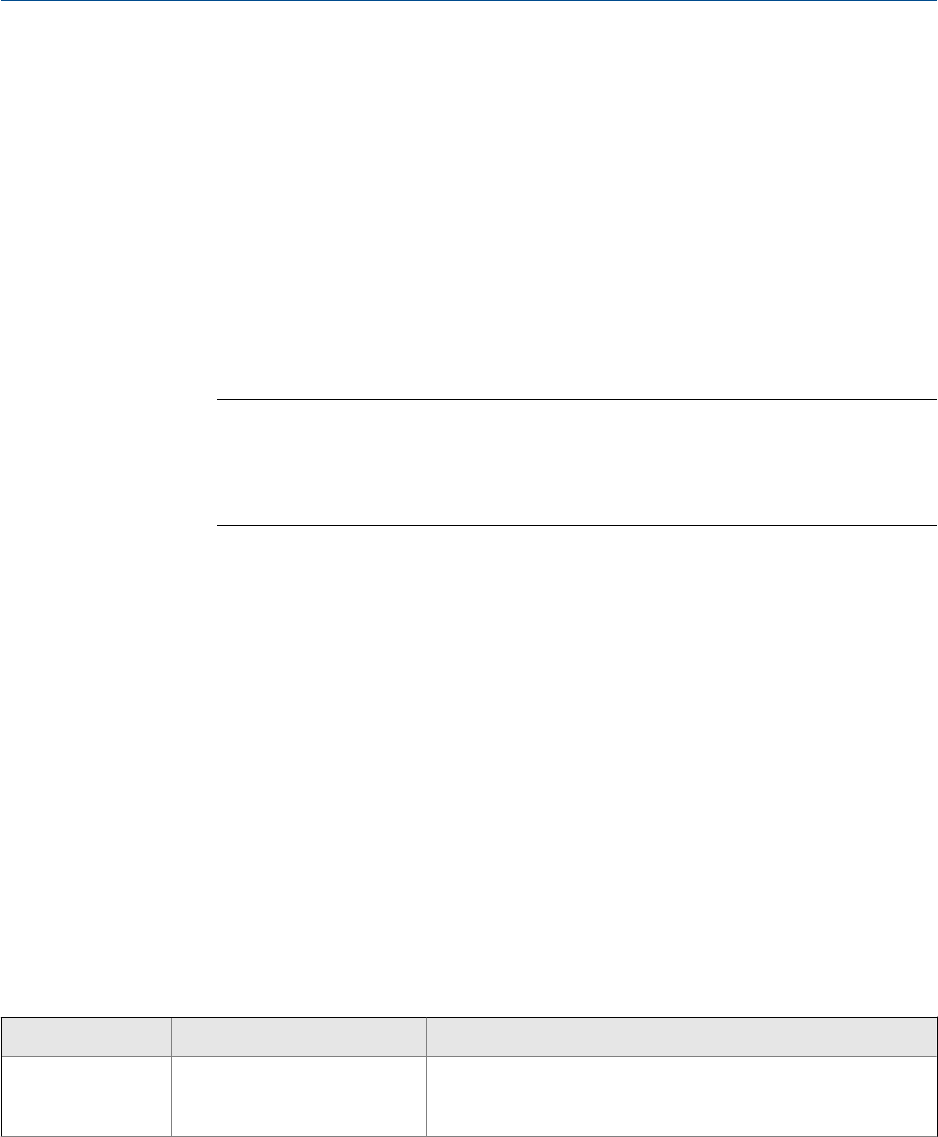

Option Description Setup

Internal RTD tem-

perature data

Temperature data from the on-

board temperature sensor

(RTD) is used.

a. Set Line Temperature Source to Internal RTD.

b. Click Apply.

Configure process measurement

Configuration and Use Manual 47