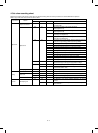

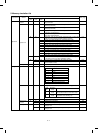

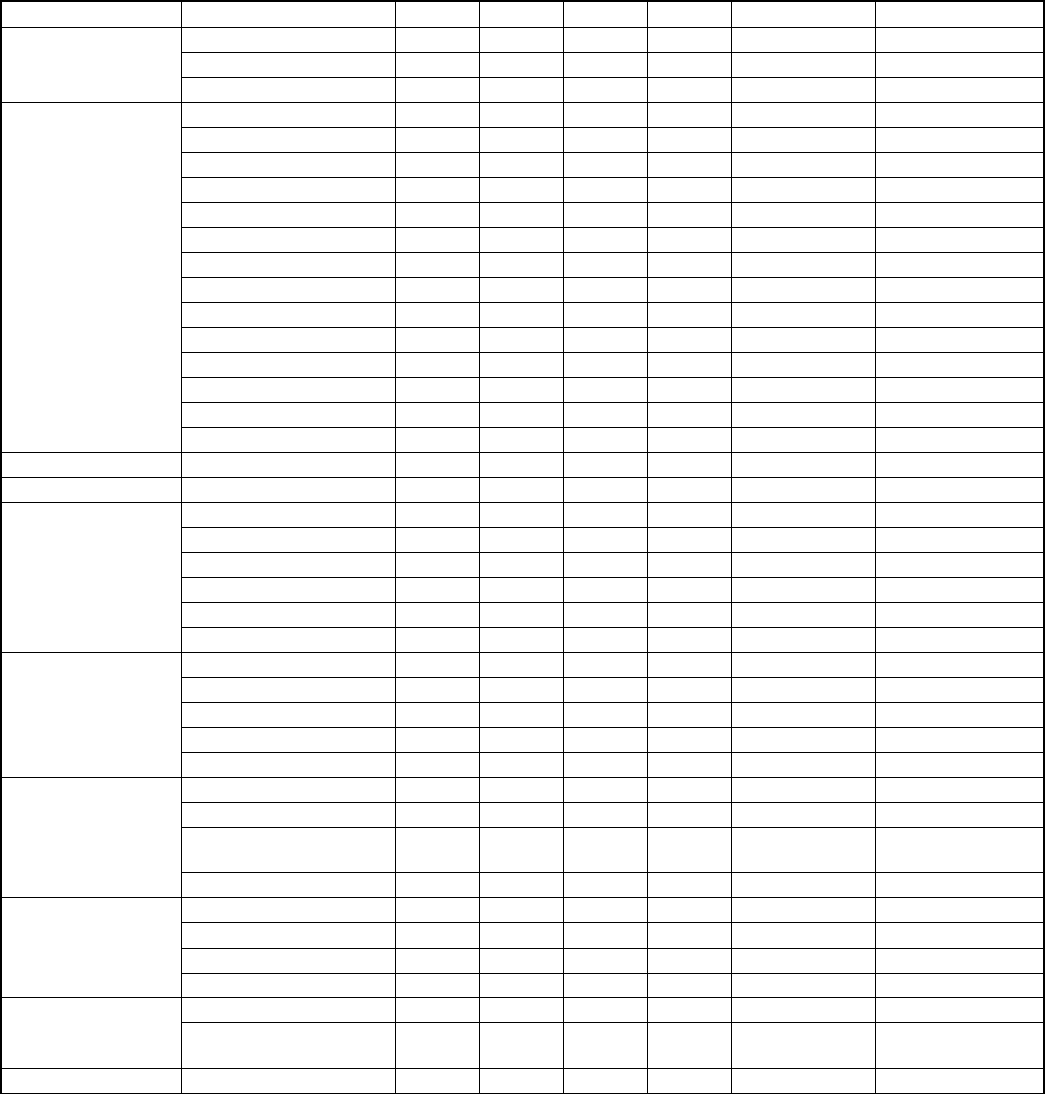

[11] MAINTENANCE

1. Maintenance cycle and maintenance items

Maintenance of the SF-1020/1120 should be performed at every 50K.

<Content> ★ = Lubricate, F = Clean, v = Adjust, b = Replace/attach, ê = Shift position

✕ = Check (Clean, replace, or adjust if necessary.)

* The toner consumption and the waste toner bottle replacement cycle are those when the reference chart is used.

Section Parts 50K 100K 150K 200K Same cycle later Remark

Developing

Developer bbbb

DV blade FbFb

DV side seal (F/R) FbFb

Process peripheral

Drum bbbb

Cleaner blade bbbb

Toner reception seal bbbb

Drum separation seal bbbb

Charging plate (saw teeth) FbFb

MC case FFFF

Screen grid FbFb

Discharge lamp FFFF

Blank lamp FFFF

Drum mark sensor FFFF

Drum density sensor FFFF

Waste toner bottle bbbb

TC/SC case FFFF

TC/SC wire FbFb

Suction Suction belt FFFF

Ozone filter Ozone filter ✕ F ✕ F

Fusing

Upper heat roller ✕ b ✕ b

Lower heat roller ✕ b ✕ b

Upper separation pawl FbFb

Lower separation pawl ✕ b ✕ b

Thermistor FFFF

Heat roller gear ★ b ★ b

Optical

Mirror/lens/reflector FFFF

Drive wire/pulley ✕✕✕✕

Rails ✕★✕★

Table glass FFFF

Dust-proof glass FFFF

Paper feed

(including multi paper

feed section)

Pick-up roller F (✕) F (✕) F (✕) b

Paper feed roller F (✕) F (✕) F (✕) b

Separation roller F (✕) F (✕) F (✕) b

Do not use alcohol.

Wipe with water.

Torque limiter section ✕✕✕b

Transport

PC roller pair FFFF

Transport roller pair FFFF

Transport paper guides FFFF

Transport system sensors FFFF

Drive

Belts FFFF

Gears

(specified gears only)

★★★★

Image vvvv

11 – 1