Teledyne API T703/T703U Calibrator Operation Manual General Troubleshooting & Service

175

8.4.7. RELAY PCA

The Relay PCA can be most easily checked by observing the condition of the status

LEDs located along its upper edge (see Section 8.3.2 and Figure 8-3: Relay PCA

Status LEDs Used for Troubleshooti

ng), and using the SIGNAL I/O submenu under the

DIAG menu (see Section 8.1.3) to toggle each LED ON or OFF.

If D1 on the

Relay PCA is flashing and the status indicator for the output in question

(Pump power, Heater power, Valve Drive, etc.) toggles properly using the Signal I/O

function, then the associated control device on the Relay PCA is bad. Several of the

control devices are in sockets and can be easily replaced. The table below lists the

control device associated with a particular function.

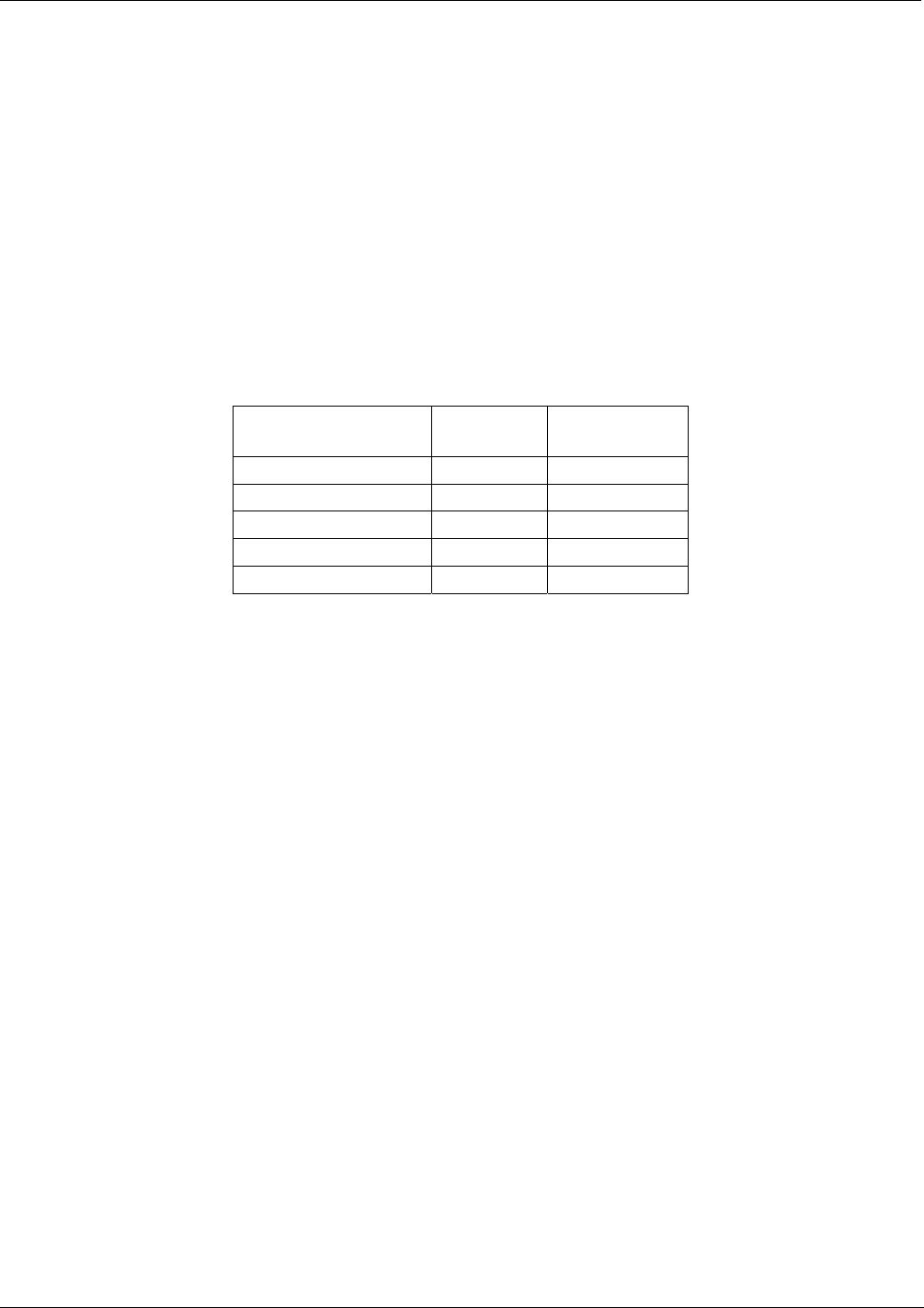

Table 8-8: Relay PCA Control Devices

FUNCTION

CONTROL

DEVICE

IN SOCKET

UV Lamp Heater Q2 No

O

3

Gen Heater Q3 No

All Valves U5 Yes

AC Dry air Pump K1 No

DC Photometer Pump U1 No

8.4.8. PHOTOMETER O

3

GENERATOR PRESSURE /FLOW SENSOR

ASSEMBLY

This assembly is only present in calibrators with O

3

generator and/or photometer

installed. The pressure/flow sensor PCA, located at the rear of the instrument between

the O

3

generator and the photometer pump (see Figure 3-5 for T703; see Figure 3-7 for

T703U) can be checked with a Voltmeter. The following procedure assumes that the

wiring is intact and that the motherboard as well as the power supplies are operating

properly:

BASIC PCA OPERATION:

Measure the voltage across C1; it should be 10 VDC ± 0.25 VDC. If not then the

board is bad.

Measure the voltage between TP2 and TP1 C1; it should be 10 VDC ± 0.25 VDC. If

not then the board is bad.

Measure the voltage across C2; it should be 5 VDC ± 0.25 VDC. If not then the

board is bad.

07223C DCN6572