IM 01E20C01-01E

10-5

10. MAINTENANCE

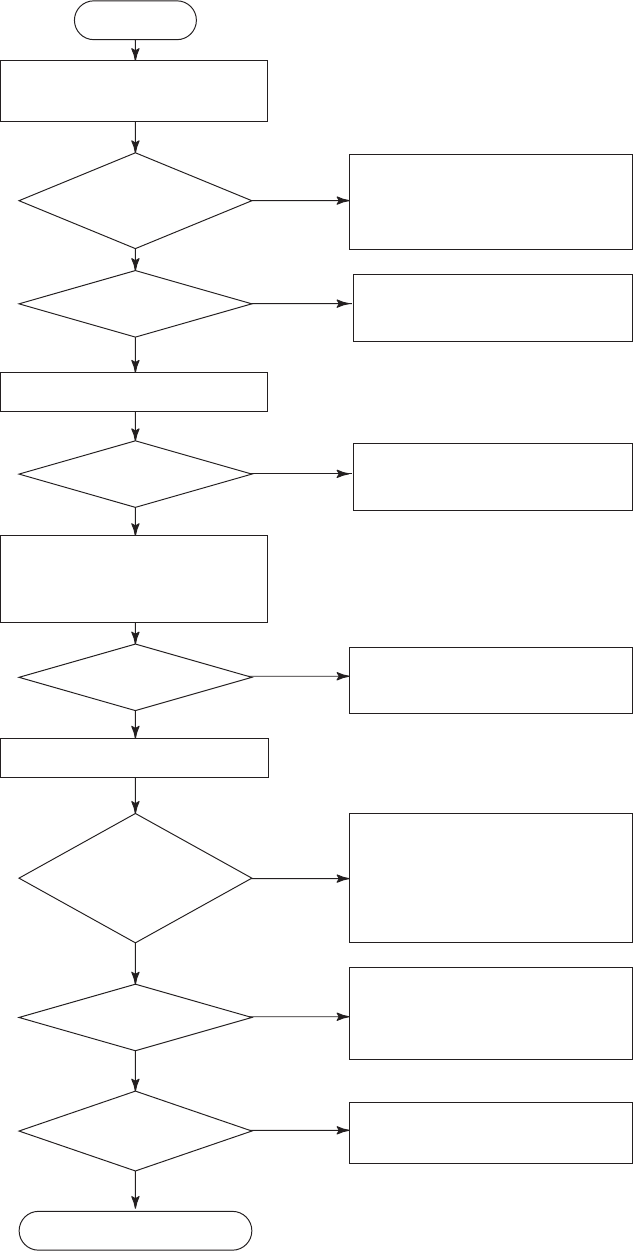

10.3.2 Unstable Zero

START

Check for the presence of valve

leakage.

• Confirm the flowmeter grounding.

• Confirm whether or not the

grounding wire is disconnected

from the earth flange.

Recheck the fluid to be measured.

Particular care must be taken in the case

of horizontal mounting. In order to ensure

complete filling of the tube, either adjust

the mounting position or switch to vertical

mounting.

Install a defoaming device on the

flowtube’s upstream side.

Replace the valve(s).

Completely ground the converter and

flowtube (Refer to the section on

grounding in the relevant user’s manual).

• Ensure that the fluid’s conductivity

changes as little as possible.

• Do not use the meter when fluid

conductivity is out of limits.

• Whenever possible, reduce the flow

velocity to being in the vicinity of the

lower conductivity limit.

• Remove dirt and scale of and near

electrodes.

• Use a soft brush or cloth to perform

scale removal, and make sure that

the lining is not damaged.

Provide the meter with sufficient

shielding or move it away from the

electrical equipment

NO

NO

NO

NO

NO

NO

NO

YES

YES

YES

YES

YES

YES

YES

Are there bubbles

in the fluid?

Are valves leaking?

Is the fluid likely to

contain deposits?

•

Does the fluid’s

conductivity vary?

•

Is the fluid conductivity

within the limits?

Is the flowtube

completely full of fluid?

Is the flowmeter properly

grounded?

Contact a service center.

*1: When checking for bubbles, it is

convenient if there is a gas vent hole

on the flowtube’s downstream side.

*1

Investigate whether or not the flowtube

is filled with fluid and that it is free of

bubbles.

Is the flowmeter

located near motors, transformers,

or electric equipment?

F1006.EPS