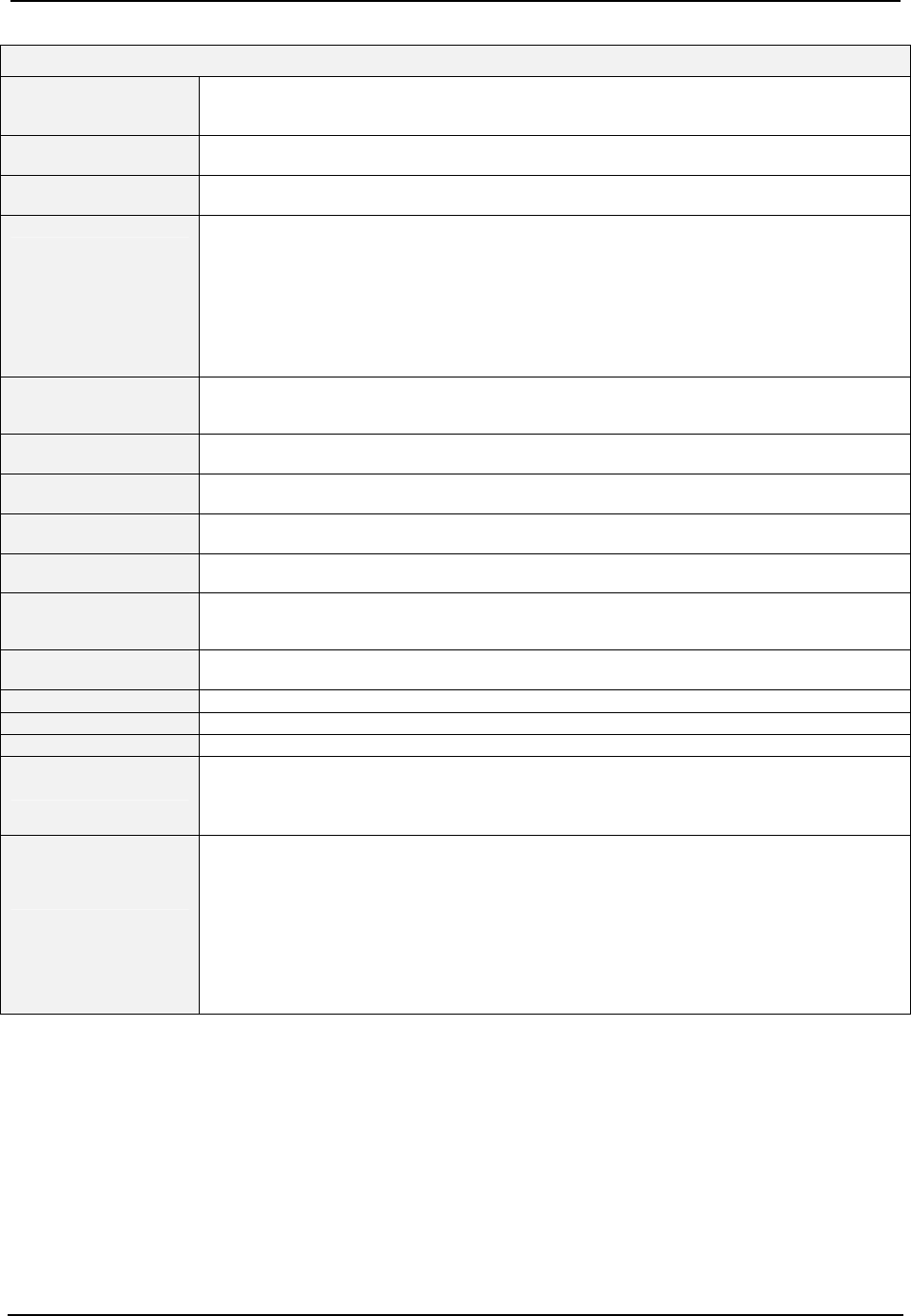

Specifications

6 UDA2182 Universal Dual Analyzer Product Manual January 2009

UDA2182 Universal Dual Analyzer

Control Loop/Outputs Control Loops: 2 standard (one for each PV); current, pulse frequency, or time proportional

Control Loop Types: PID (optional), Duplex (optional), On/Off (standard)

Auto-tuning: Accutune II, fuzzy logic overshoot suppression, applicable to both PID loops

Standard Alarm/ Control

Relays

Two SPDT (Form “C”) Relays

Resistive Load Rating: 4A, 120/240 Vac

Optional Additional

Alarm/Control Relays

Two SPDT (Form “C”) Relays

Resistive Load Rating: 4A, 120/240 Vac

Alarm/Control Settings Alarm/on-off control delay: 0-100 seconds.

Alarm/on-off control deadbands: individually set, from 1 count to full scale for pH, ORP, and

temperature.

On/off cycle period: 0 to 1000 seconds.

On/off percent “on” time: 0 to 100%, 1% resolution.

Set point and proportional band limit ranges: ±19.99 pH, ±1999 mV, -10 to 130°C, 1 count resolution.

DAT cycle period: 1 to 1999 seconds.

PFT maximum frequency: 1 to 200 pulses/minute.

PFT pulse width: 50 ms, compatible with electronic pulse-type metering pumps.

Remote Preamplifier Input

Option

Optional input card to accept input signal from Honeywell digital preamplifiers:

Meridian II – 31075707 and 31022283

Durafet – 31079288 and Cap Adapter cables

pH Temperature

Compensation

Conventional compensation for changing electrode output (Nernst response), plus selectable solution

temperature compensation for high-purity water.

Calculated pH from

Differential Conductivity

User selectable when unit has two Conductivity inputs. Used when ammonia or amine is the water

treatment chemical.

Auto Buffer Recognition

(pH)

User Selectable

Available Buffer Series: NIST/USP, US, and Euro

Conductivity

Compensations

NaCl, HCl, H

2

SO

4

, PO

4

, NaOH, NH

3

, C

4

H

9

C, Pure Water, Custom (User Selectable)

Dissolved Oxygen

Measurement

Max flowrate (probe): 950 ml/min with flow chamber; no dependence on stirring or flowrate

Atmospheric pressure: 500-800 mm Hg with internal sensor, for calibration

Calibration with either Air or Sample

Auto Clean/ Auto Cal

Function

Real time clock is used to set-up cycles to initiate a cleaning and calibration sequence. Cycle Set-up is

user configurable.

Event History Screen Event history screen stores 256 events with a description of the event and a Date/time stamp.

Calibration History Screen Calibration history screen stores information on 128 calibration events with a date/time stamp.

Power Requirements 90 -264 Vac, 47-63 Hz, 15 VA. Memory retained by E

2

PROM when power is off.

Wireless Interface

Type: Infrared (IR)

Length of Link: 0 –1 M, 0 –15° Offset

Baud Rate: 9600

Data Format: Modbus Protocol

RS422/RS485 Modbus

RTU Slave

Communications Interface

(Optional)

Baud Rate: 2400, 4800, 9600, 19200, 38400, 57600, or 115200 selectable

Data Format:: IEEE floating point and 32-bit integer. Word swap configurable.

Length of Link:

2000 ft (600 m) max. with Belden 9271 Twinax Cable and 120 ohm termination resistors

4000 ft (1200 m) max. with Belden 8227 Twinax Cable and 100 ohm termination resistors

Link Characteristics: Two-wire (half-duplex), multi-drop Modbus RTU protocol, 15 drops maximum or

up to 31 drops for shorter link length.

Modbus RTU slave: Provides monitoring of inputs outputs, statuses, alarms, and variables. Provides

writing of variables for remotely modifying parameter settings.