Unpacking

January 2009 UDA2182 Universal Dual Analyzer Product Manual 11

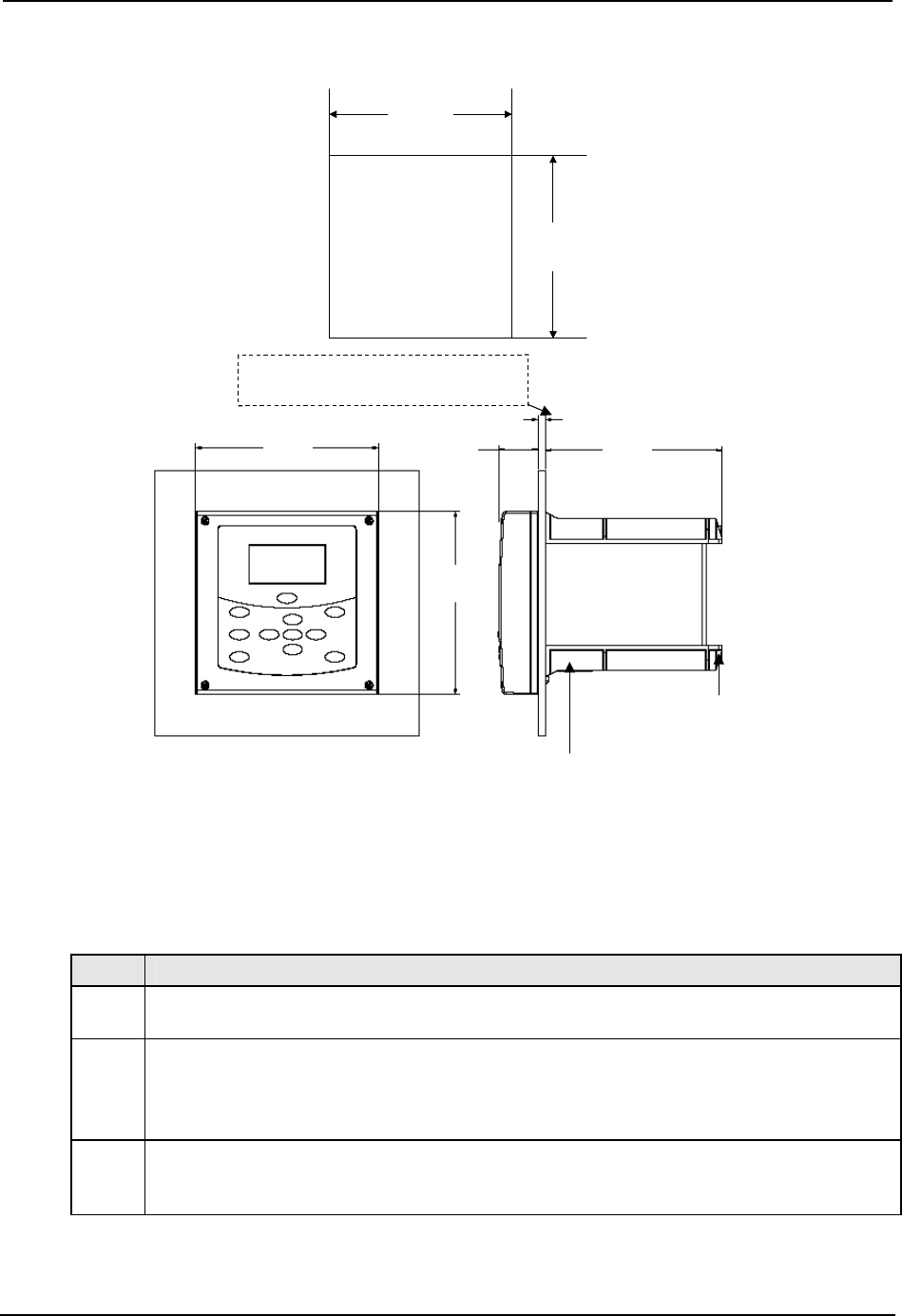

Panel Mounting Dimensions

156

[6.14]

156

[6.14]

152

[5.98]

33.5

[1.32]

138

[5.43]

+1

-0

+.04

-0

138

[5.43]

+1

-0

+.04

-0

Panel Cutout

(4) 22.22[.87] holes for

lead wires and conduit fittings

(conduit fittings supplied by user)

Customer will need to provide a rear panel support

plate to maintain NEMA4 protection if primary

panel thickness is less that 2.3mm [0.09”] thick

CUSTOMER PANEL

1.6[.06] to 6.35 MAX[0.25]

156

[6.14]

156

[6.14]

152

[5.98]

33.5

[1.32]

138

[5.43]

+1

-0

+.04

-0

138

[5.43]

+1

-0

+.04

-0

138

[5.43]

+1

-0

+.04

-0

138

[5.43]

+1

-0

+.04

-0

Panel Cutout

(4) 22.22[.87] holes for

lead wires and conduit fittings

(conduit fittings supplied by user)

Customer will need to provide a rear panel support

plate to maintain NEMA4 protection if primary

panel thickness is less that 2.3mm [0.09”] thick

CUSTOMER PANEL

1.6[.06] to 6.35 MAX[0.25]

Figure 3-1 Panel Mounting Dimensions (not to scale)

Panel Mounting Procedure

Table 3-2 Panel Mounting Procedure

Step Action

1

Mark and cut out the analyzer hole in the panel according to the dimension information

in Figure 3-1.

2

Orient the case properly and slide it through the panel hole from the front.

Customer will need to provide a rear panel support plate to maintain NEMA4

protection if primary panel thickness is less that 2.3mm [0.09”] thick –

See Figure 3-2.

3

Remove the mounting kit from the shipping container and clamp the edges of the

cutout between the case flange and the supplied U-bracket that is fastened to the rear

of the case using (2) M5 X 16mm long screws and (2) M5 lock washers supplied.