Appendices

204 UDA2182 Universal Dual Analyzer Product Manual January 2009

15.4 Appendix C - Cyanide Waste Treatment

Introduction

Uses of cyanide solutions

Cyanide solutions are used in plating baths for zinc, cadmium, copper, brass, silver and

gold. The toxic rinse waters and dumps from these operations require destruction of the

cyanide (typically to a level below 0.1 ppm) before its discharge.

Technique for cyanide destruction

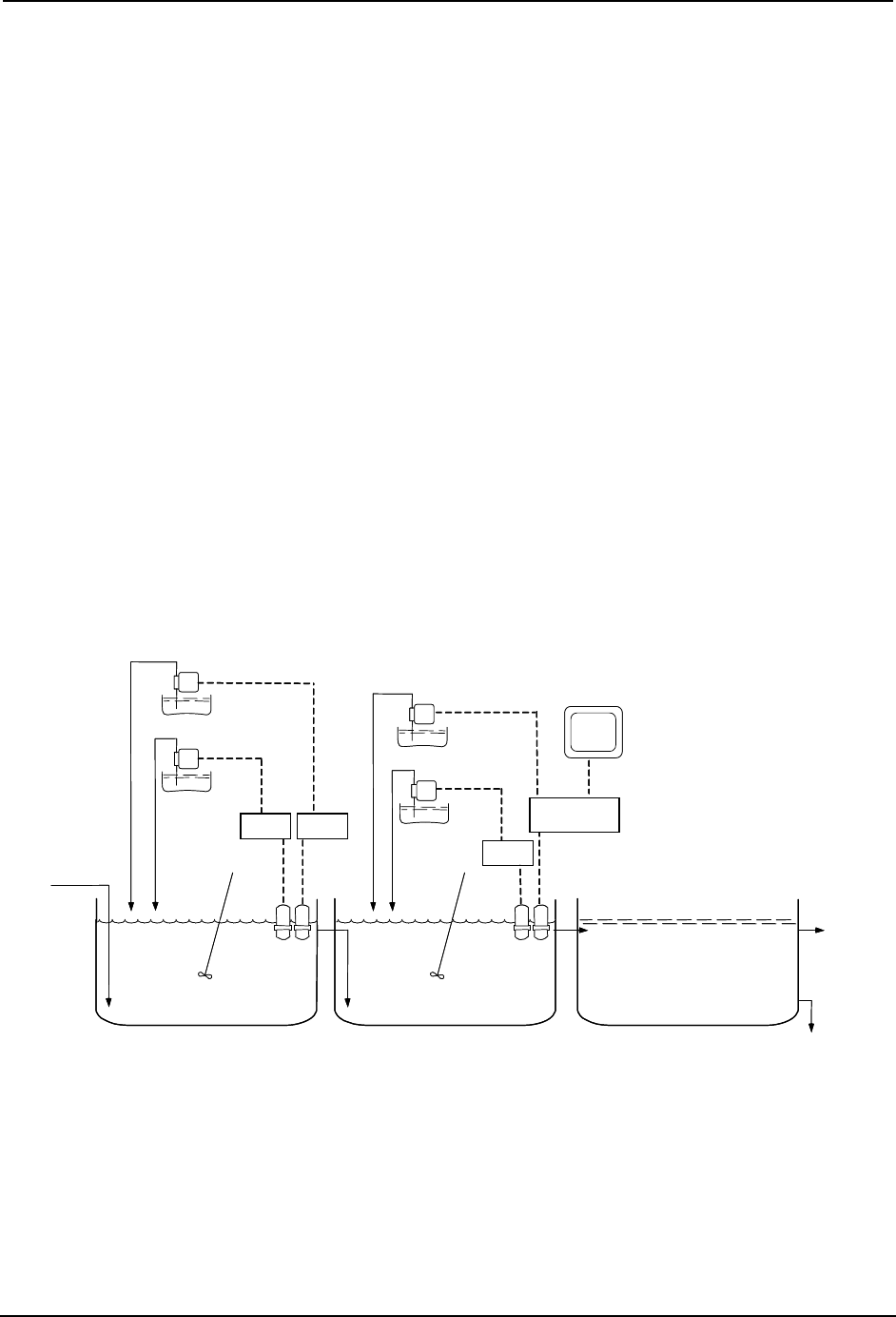

The technique most often used for cyanide destruction is a one or two-stage chemical

treatment process. The first stage raises the pH and oxidizes the cyanide to less toxic

cyanate. When required, the second stage neutralizes and further oxidizes the cyanide to

harmless carbonate and nitrogen. The neutralization also allows the metals to be

precipitated and separated from the effluent.

Consistent treatment and stable control in this type of process requires well-mixed

reaction tanks with enough volume for adequate retention time. See Figure 15-3.

Retention time is calculated by dividing the filled or usable tank volume by the waste

flowrate. Typically it is 10 minutes or more.

pH ANALYZER

CONTROLLER

RECORDER

PROPORTIONAL

ACID

NOTE: The separate pH and ORP

measurements and control shown

in the first stage may be handled

with a single UDA2182 Analyzer

with combined input.

ON/OFF

HYPOCHLORITE

ORP

HYPOCHLORITE

ON/OFF

ON/OFF

CAUSTIC

ORP pH

CYANIDE

WASTE

CYANIDE TO CYANATE CYANATE TO CARBONATE

AND NEUTRALIZATION

SETTLING SLUDGE

pH ANALYZER

CONTROLLER

pH ANALYZER

CONTROLLER

RECORDER

PROPORTIONAL

ACID

NOTE: The separate pH and ORP

measurements and control shown

in the first stage may be handled

with a single UDA2182 Analyzer

with combined input.

ON/OFF

HYPOCHLORITE

ORPORP

HYPOCHLORITE

ON/OFF

ON/OFF

CAUSTIC

ORPORP pH

CYANIDE

WASTE

CYANIDE TO CYANATE CYANATE TO CARBONATE

AND NEUTRALIZATION

SETTLING SLUDGE

Figure 15-3 Cyanide Treatment System