Appendices

208 UDA2182 Universal Dual Analyzer Product Manual January 2009

15.5 Appendix D – Chrome Waste Treatment

Use of Chromates

Corrosion inhibition

Chromates are used as corrosion inhibitors in cooling towers and in metal-finishing

operations including bright dip, conversion coating, and chrome plating.

Necessity for removal of chromium ion from wastewater

The wastewater form rinse tanks, dumps, and cooling tower blowdown contains toxic

soluble chromium ion, Cr

+6

, which must be removed, typically to a level less than 0.5

ppm before discharge.

Technique for chrome removal

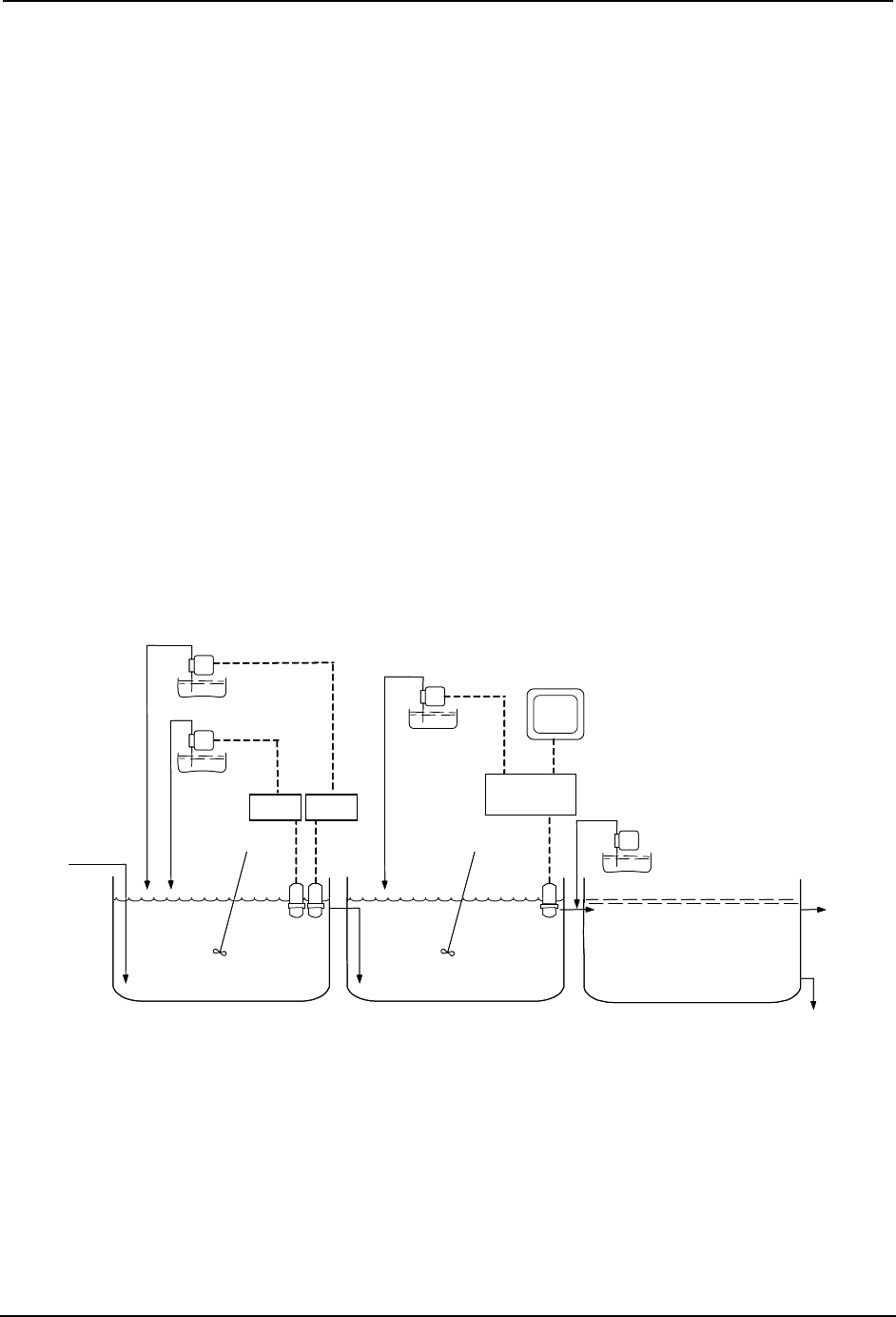

The technique most often used for this chrome removal is a two-stage chemical treatment

process. The first stage lowers the pH and adds the reducing agent to convert the chrome

from soluble Cr

+6

to Cr

+3

. The second stage neutralizes the wastewater, forming insoluble

chromium hydroxide, which can then be removed.

Consistent treatment and stable control in this type of process requires well-mixed

reaction tanks with enough volume for adequate retention time (see Figure 15-5).

Retention time is calculated by dividing the filled or usable tank volume by the waste

flowrate. Typically, it is ten minutes or more.

RECORDER

PROPORTIONAL

NOTE: The separate pH and ORP

measurements and control shown

in the first stage may be handled

with a single UDA2182 Analyzer

with combined input

CAUSTIC

Ph ANALYZER/

CONTROLLER

POLYELECTROLYTE

BISULFITE

ON/OFF

ON/OFF

ACID

pH

ORP

CHROME

WASTE

REDUCTION NEUTRALIZATION SETTLING

SLUDGE

RECORDER

PROPORTIONAL

NOTE: The separate pH and ORP

measurements and control shown

in the first stage may be handled

with a single UDA2182 Analyzer

with combined input

CAUSTIC

Ph ANALYZER/

CONTROLLER

Ph ANALYZER/

CONTROLLER

POLYELECTROLYTE

BISULFITE

ON/OFF

ON/OFF

ACID

pHpH

ORPORP

CHROME

WASTE

REDUCTION NEUTRALIZATION SETTLING

SLUDGE

Figure 15-5 Chrome Treatment System