Appendices

January 2009 UDA2182 Universal Dual Analyzer Product Manual 205

First Stage of Cyanide Destruction

Raise pH and oxidize cyanide

Sodium hydroxide (caustic) is used to raise the effluent to about 11 pH, which will

promote the oxidation reaction and ensure complete treatment. The oxidizing agent is

usually sodium hypochlorite, NaOCl. The reaction for the first stage is given below using

the NaOCl and with cyanide expressed in ionic form (CN

-

). The result is sodium cyanate

(NaCNO) and chloride ion (Cl

-

).

NaOCl CN NaCNO Cl+→ +

−−

This first-stage reaction is analyzed and controlled by independent control loops: caustic

addition by pH control and oxidizing-agent addition by ORP control (redox potential or

ORP, oxidation-reduction potential). Often an ON-OFF type of control using solenoid

valves or metering pumps can be used. The pH controller simply calls for more caustic

whenever pH falls below 11. The ORP controller calls for additional hypochlorite

whenever ORP potential falls below about +450 mV. (The metal ORP electrode is

positive with respect to the reference electrode.)

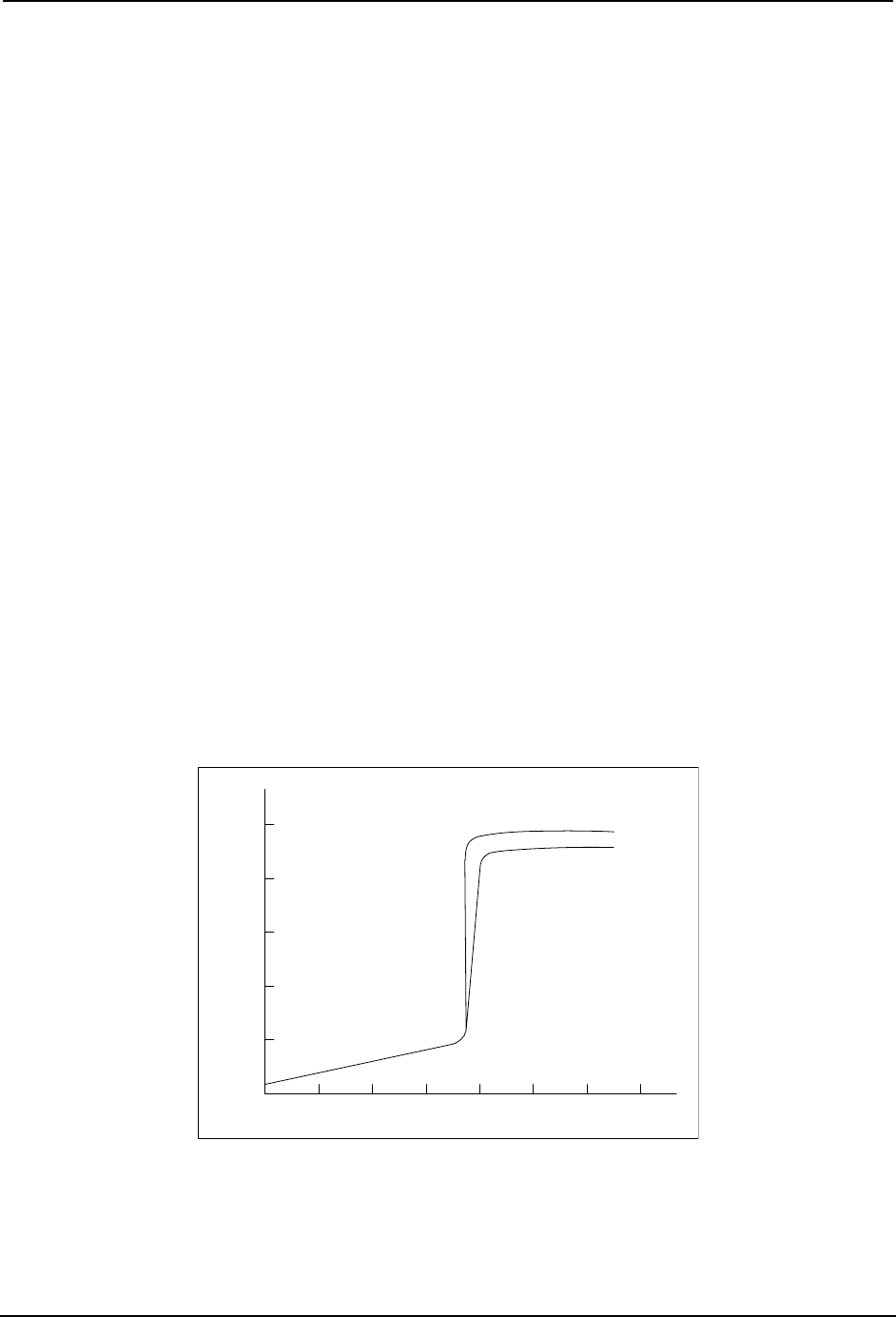

Titration curve

The ORP titration curve in Figure 15-4 shows the entire millivolt range if cyanide is

treated as a batch. For continuous treatment, operation is maintained in the oxidized,

positive region of the curve near the +450 mV setpoint. The ORP setpoint can vary

between installations, depending upon pH, the oxidizing agent, the presence of various

metals in solution, and the type of reference electrode used. Determine the exact setpoint

empirically at that potential where all the cyanide has been oxidized without excess

hypochlorite feed. This point can be verified with a sensitive colorimetric test kit or

similar check for cyanide.

VOLUME OF HYPOCHLORITE ADDED

REDOX POTENTIAL (mV)

0

1

2

3

4

5

6

7

-400

-200

0

+200

+400

+600

pH= 10.5

pH= 11.0

Figure 15-4 First Stage Cyanide Oxidation - Typical Titration Curve