2 Specifications

MITSUBISHI CNC

2 - 62

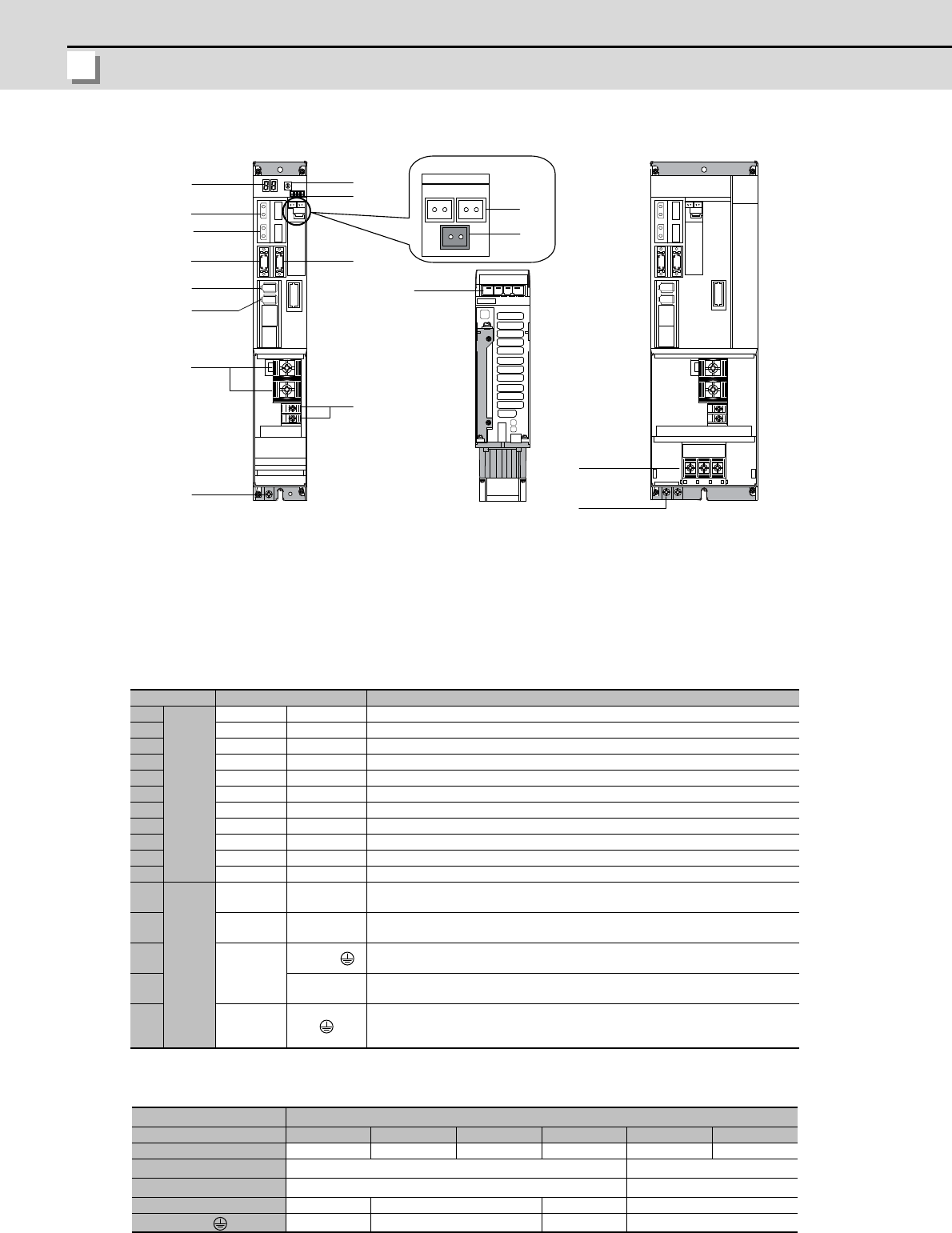

(c) Explanation of each 1-axis spindle drive unit part

The connector and terminal block layout may differ according to the unit being used. Refer to each unit

outline drawing for details.

<Each part name>

<Screw size>

Name Description

(1)

Con-

trol cir-

cuit

LED --- Unit status indication LED

(2) SWL --- Axis No. setting switch

(3) SW1 --- Unused axis setting switch

(4) CN1A --- NC or master axis optical communication connector

(5) CN1B --- Slave axis optical communication connector

(6) BTA,BTB --- (Unused)

(7) BT1 --- (Unused)

(8) CN9 --- Maintenance connector (usually not used)

(9) CN4 --- Power supply communication connector

(10) CN2L --- Motor side detector connection connector 5V power supply capacity:0.35A

(11) CN3L --- Spindle side detector connection connector 5V power supply capacity:0.35A

(12)

Main

circuit

TE2

L+

L-

Converter voltage input terminal (DC input)

(13) TE3

L11

L21

Control power input terminal (single-phase AC input)

(14)

TE1

U, V, W,

Motor power supply output connector (3-phase AC output),

Motor grounding terminal (for 60mm width)

(15) U, V, W

Motor power supply output terminal (3-phase AC output)

(for 90mm width or more)

(16) PE

Grounding terminal, Motor grounding terminal

Note that TE1 connector (above "(14)") is used for the motor grounding of the 60mm

width unit.

Spindle drive unit MDS-D-SP-

Type 20,40,80 160 200 240,320 400 640

Unit width (mm) 60 90 120 150 240 300

(12) TE2 M6 x 16 M10 x 20

(13) TE3 M4 x 12 M4 x 8

(15) TE1 - M5 x 12 M8 x 12 M10 x 20

(16)

M4 x 12 M5 x 12 M8 x 12 M10 x 20

MDS-D-SP

60mm width

Bottom view of left diagram

MDS-D-SP

90mm width or more

(6)

(7)

(15)

(16)

(2)

(3)

(9)

(12)

(14)

(1)

(4)

(5)

(8)

(10)

(11)

(13)

1 2

1 2 1 2

(16)