7 - 13

MDS-D/DH Series Specifications Manual

7-2 Selection of the spindle motor

7-2 Selection of the spindle motor

(1) Calculation of average output for spindle

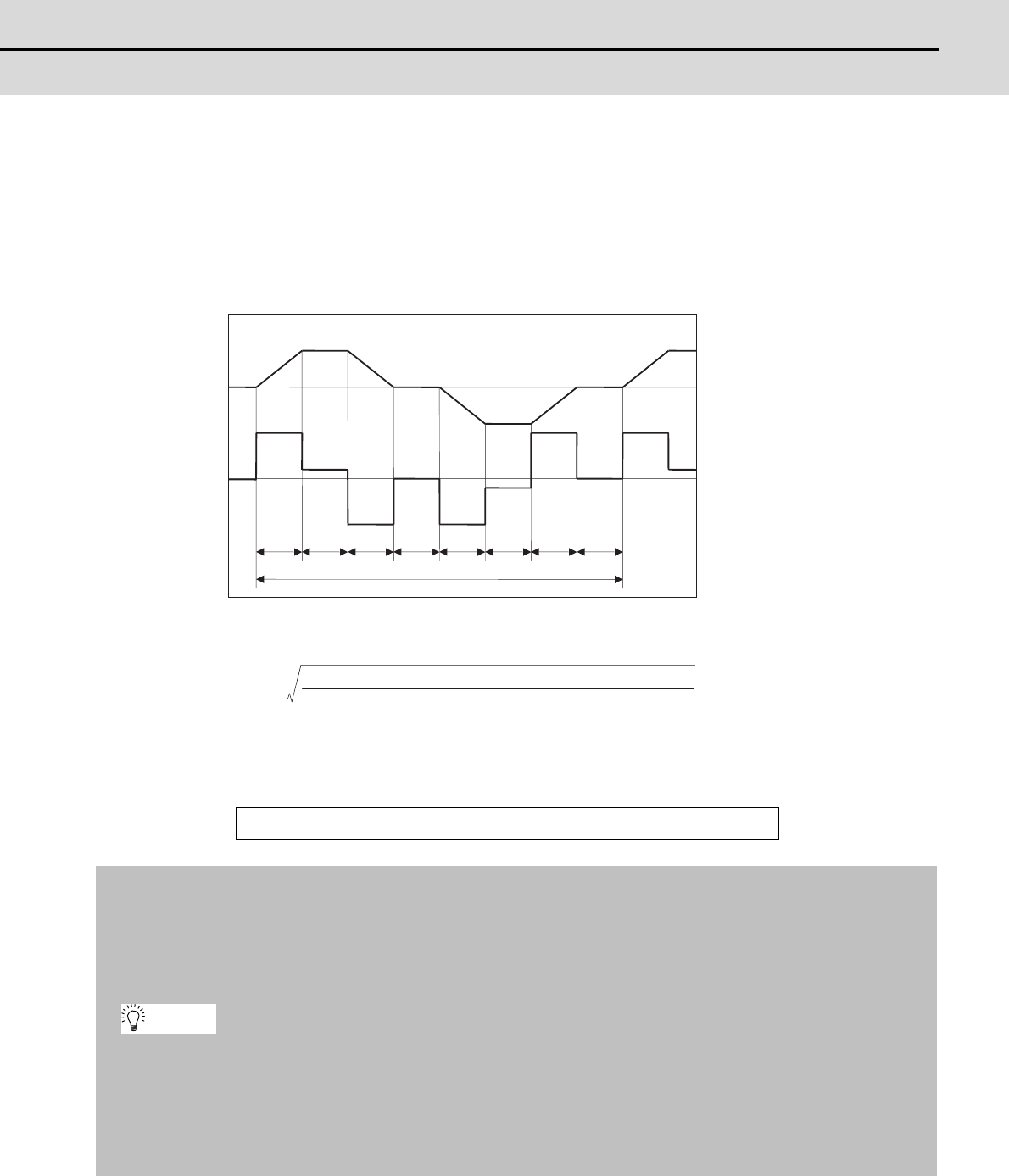

In the machine which carries out the spindle’s acceleration/deceleration frequently (example: tapping

center), short-time rating is frequently used, and a rise in temperature become significant on the spindle

motor or drive unit. Thus, calculate the average output (P

AV

) from one cycle operation pattern and confirm

that the calculated value is less than the continuous rating output of the selected spindle motor.

Continuous operation pattern (example)

P1 to P8 :Output

t1 to t8 :Time

t0 :One cycle operation time

1. Calculate acceleration/deceleration time by the accurate load inertia because even if the rotation

speed is the same, acceleration/deceleration time varies with a tool or workpiece mounted to the

spindle.

Refer to the section "Adjusting the acceleration/deceleration operation" (1) in Instruction Manual.

2. Calculation method of synchronous tapping

The acceleration/deceleration number of times is twice, for forward run and reverse run are carried

out in one machining. The output guideline is 50% of the short-time rating. The time is tapping time

constant.

3. Calculation method of spindle synchronization

The output guideline is 70% of the short-time rating. The time is spindle synchronization time

constant.

0

0

P3

P2

t1 t2 t3 t4

t0

P1

P4

P5

P6

P7

P8

t5 t6 t7 t8

[1]

[2]

[3]

[4]

[5]

[6]

[7]

[8]

Motor

torque

Motor

speed

Time

Output during

acceleration/deceleration(kw)

Short-time rating ×1.2

Accelera-

tion

Accelera-

tion

Decelera-

tion

Decelera-

tion

Cutting

Cutting

Stop

Stop

PAV =

P1

2

·t

1+P2

2

·t2

+P3

2

·t3

+P4

2

·t4

+P5

2

·t5

+P6

2

·t6

+P7

2

·t7

+P8

2

·t8

t0

Continuous rated output One cycle operation pattern average output (P

AV

)

POINT