2 Specifications

MITSUBISHI CNC

2 - 66

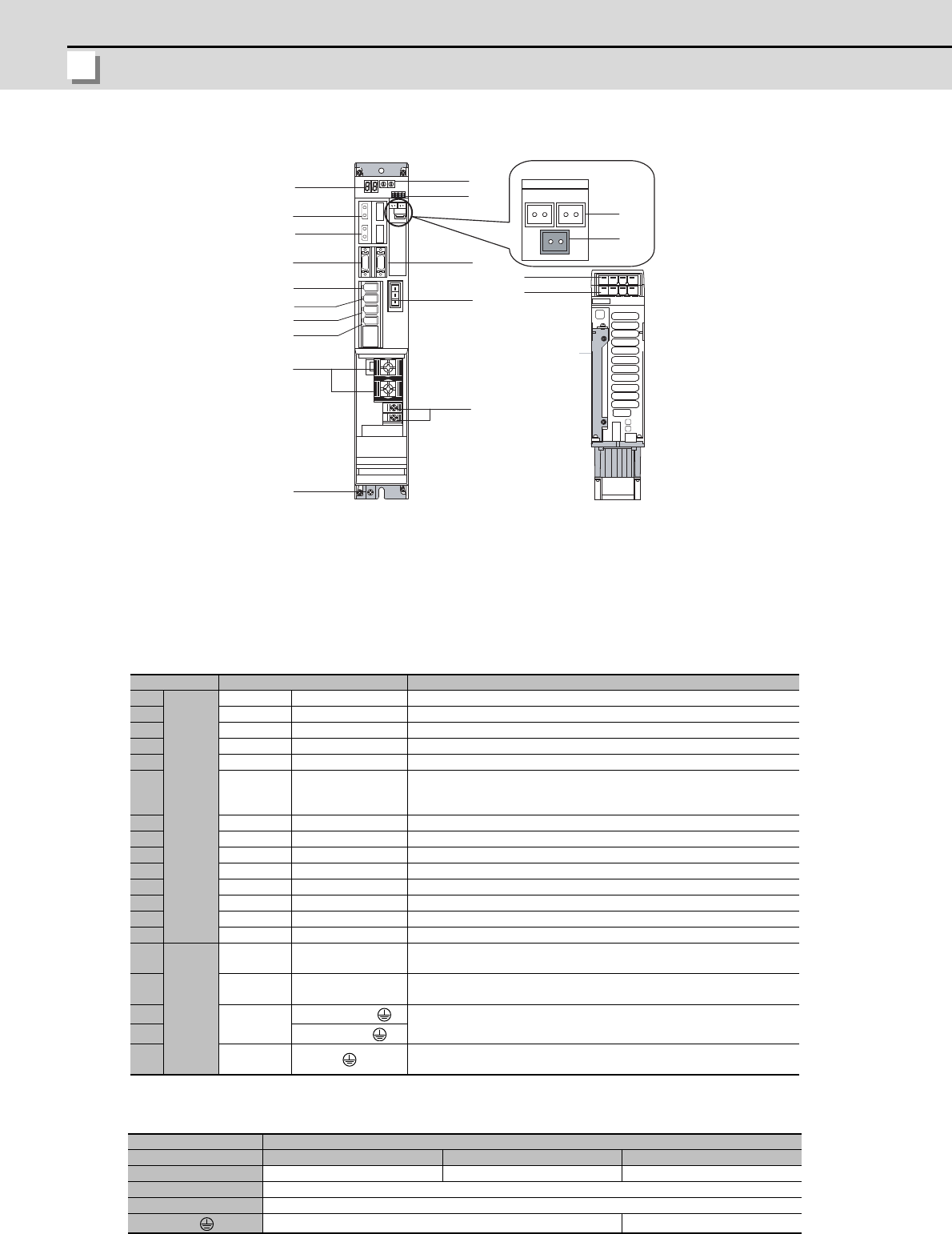

(b) Explanation of each 2-axis servo drive unit part

The connector and terminal block layout may differ according to the unit being used. Refer to each unit

outline drawing for details.

<Each part name>

<Screw size>

Name Description

(1)

Control

circuit

LED --- Unit status indication LED

(2) SWL,SWM --- Axis No. setting switch (L,M axis)

(3) SW1 --- Unused axis setting switch (L, M axis)

(4) CN1A --- NC or master axis optical communication connector

(5) CN1B --- Slave axis optical communication connector

(6) BTA,BTB ---

For connecting converged battery unit

Both BTA and BTB are the same function, and they are internally connected

each other.

(7) BT1 --- For connecting battery built-in drive unit ER6V-C119B

(8) CN9 --- Maintenance connector (usually not used)

(9) CN4 --- Power supply communication connector

(10) CN2L --- Motor side detector connection connector (L axis)

(11) CN3L --- Machine side detector connection connector (L axis)

(12) CN2M --- Motor side detector connection connector (M axis)

(13) CN3M --- Machine side detector connection connector (M axis)

(14) CN20 --- Motor brake/dynamic brake control connector (Key way: X type)

(15)

Main

circuit

TE2

L+

L-

Converter voltage input terminal (DC input)

(16) TE3

L11

L21

Control power input terminal (single-phase AC input)

(17)

TE1

MU, MV, MW,

Motor power supply output connector(3-phase AC output), Motor grounding

(18)

LU, LV, LW,

(19) PE

Grounding terminal

Use TE1 connector for the motor grounding.

2-axis servo drive unit MDS-DH-V2-

Type 1010 to 4040 8040, 8080 8080

Unit width (mm) 60 90 120

(15) TE2 M6×16

(16) TE3 M4×12

(19)

M4×12 M5×12

MDS-DH-V2

Bottom view

(2)

(3)

(4)

(5)

(1)

(9)

(12)

(14)

(17)

(15)

(8)

(10)

(11)

(13)

(6)

(7)

(16)

(18)

(19)