5 - 10

5 Dedicated Options

MITSUBISHI CNC

(1) Cell battery ( ER6V-C119B )

(a) Specifications

(Note1) ER6V-C119B is a battery built in a servo drive unit. Install this battery only in the servo drive

unit that executes absolute position control.

(Note2) This time is a guideline, so does not guarantee the back up time. Replace the battery with a

new battery as soon as a battery warning occurs.

(Note3) When using ball screw side detector OSA166ET2N/OSA105ET2, both ball screw side detector

and motor side detector need to be backed up by a battery, so the number of load shaft should

be two.

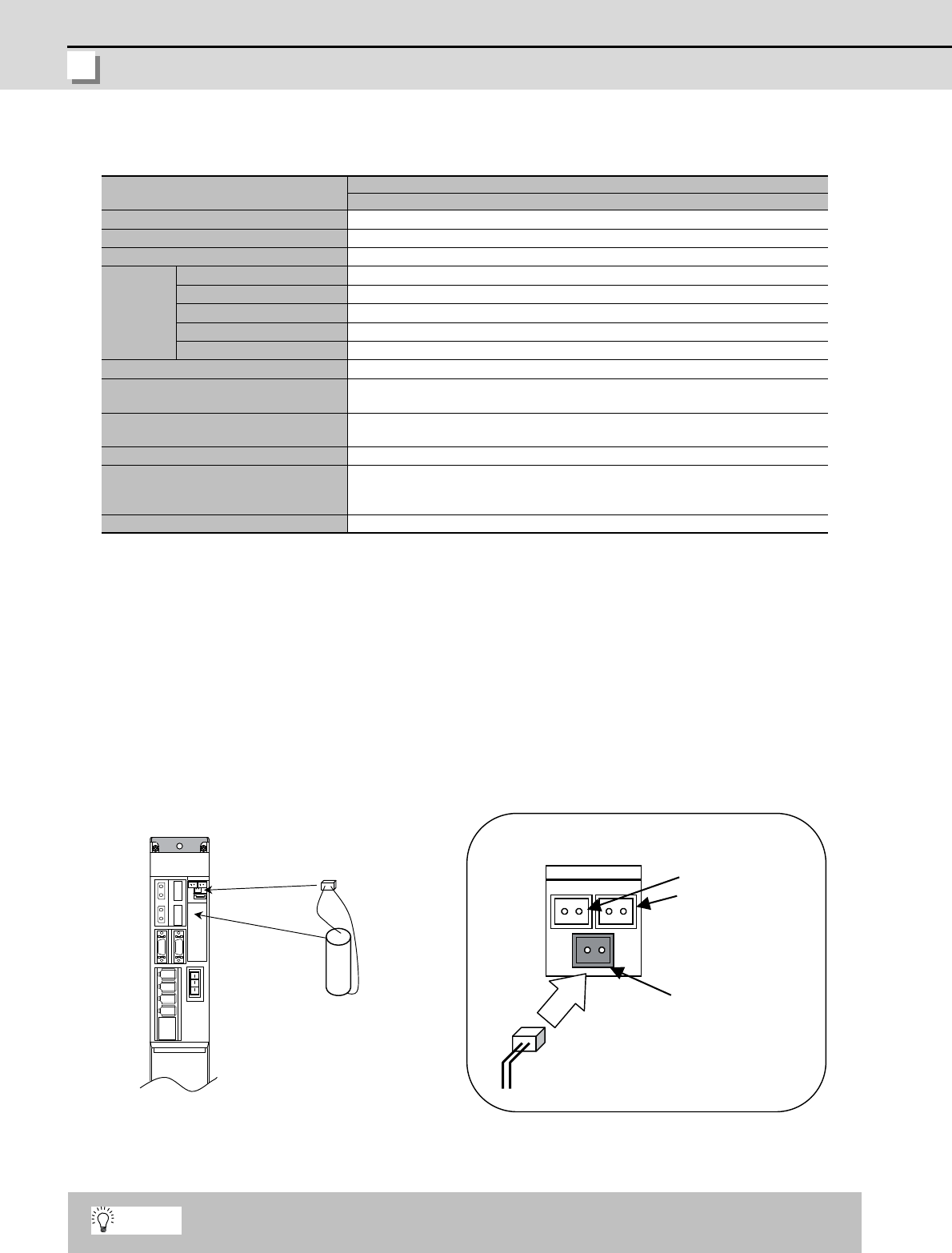

(b) Installing the cell battery

Open the upper front cover of the servo drive unit.

Connect the battery connector and then put the battery inside.

(Note) When using a cell battery, do not connect the battery unit, MDS-A-BT and MDS-BTBOX-36.

Battery option type

Cell battery

ER6V-C119B (Note1)

Lithium battery series ER6V

Nominal voltage 3.6V

Nominal capacity 2000mAh

Battery

safety

Hazard class -

Battery shape Single battery

Number of batteries used ER6V x 1

Lithium alloy content 0.7g

Mercury content 1g or less

Number of connectable axes Up to 3 axes (Note3)

Battery continuous backup time

Up to 2 axes: Approx. 10000 hours

3 axes connected: Approx. 6600 hours

Battery useful life

(From date of unit manufacture)

7 years

Data save time in battery replacement Approx. 20 hours at time of delivery, approx. 10 hours after 5 years

Back up time from battery warning to

alarm occurrence

(Note2)

Up to 2 axes: Approx. 100 hours

3 axes connected: Approx. 60 hours

Mass 20g

When using a cell battery built-in drive unit, the wiring between units is not required. The cell battery

can be changed in each drive unit.

BTA

BTB

1 2

1 2 1

2

BT1

Battery

To battery holder

Battery connector

Battery connector connection part magnified figure

Connector for

connecting cell battery

Connect the cell battery with BT1.

POINT