7 - 6

7 Selection

MITSUBISHI CNC

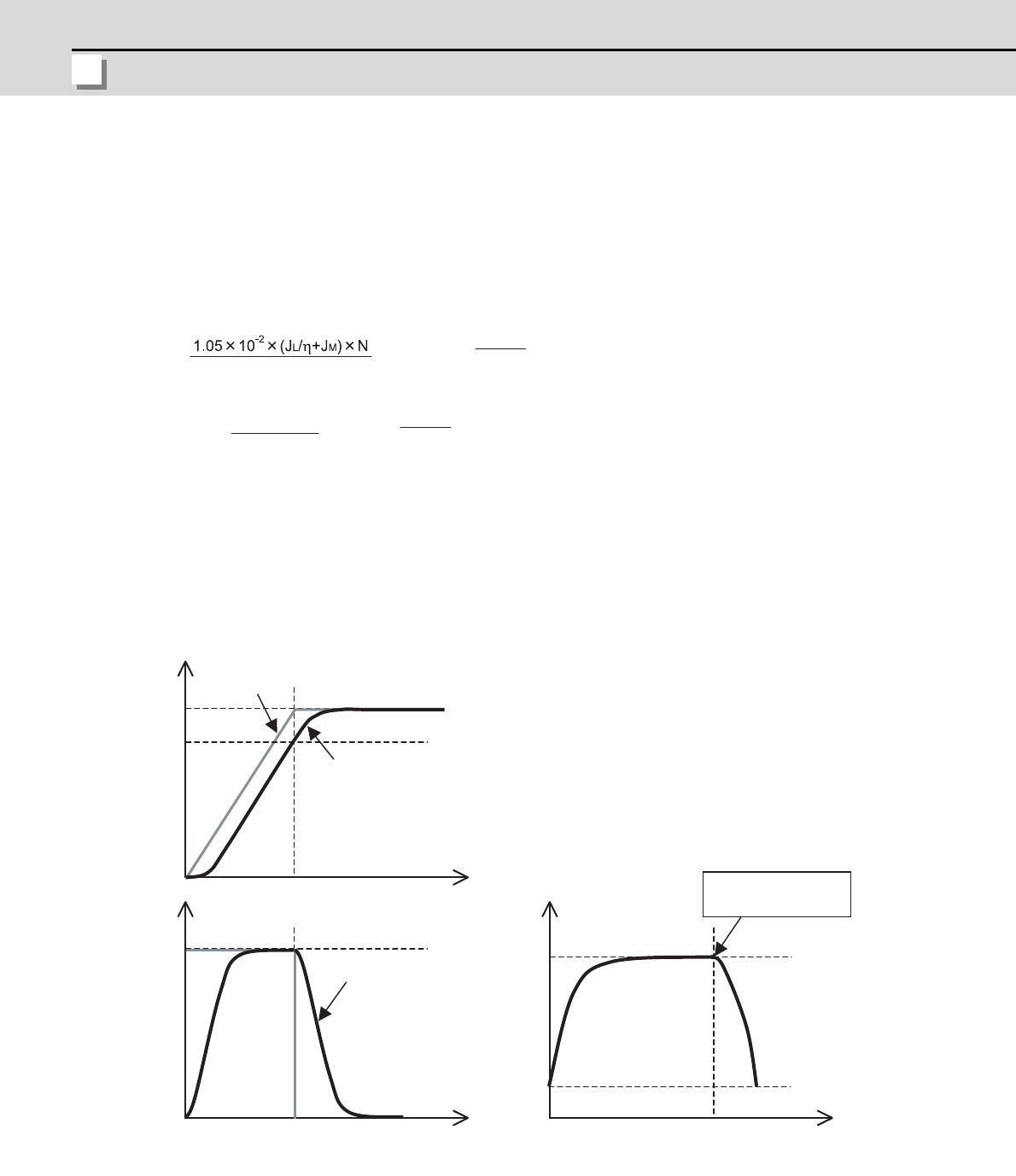

(c) Approximation when using the NC command linear acceleration/deceleration pattern + servo SHG

control (option)

This is a servo’s position control method to achieve a normal command pattern and high precision. SHG

control improves the position loop gain by stably controlling a delay of the position loop in the servo

system. This allows the settling time to be reduced and a high precision to be achieved.

Using the expression (7-5) and (7-6), approximate the maximum torque "Ta1" and maximum torque

occurrence speed "Nm" required for this acceleration/deceleration pattern.

••• (7-5)

••• (7-6)

Fig.2 Speed, acceleration and torque characteristics when using the NC command linear

acceleration/deceleration pattern + servo SHG control

N : Motor reach speed (r/min)

J

L

: Motor shaft conversion load inertia

(kg•cm

2

)

J

M

: Motor inertia

(kg•cm

2

)

η : Drive system efficiency (Normally 0.8 to 0.95)

T

MAX

: Maximum motor torque (N•m)

T

L

: Motor shaft conversion load (friction, unbalance) torque (N•m)

Ta1 =

ta

(N

.

m)

(1-

0.586

e )+TL

-2Kpta

1000

Nm =N{1-

1.3Kpta

1000

(1-1.5e )}

-2Kpta

1000

(r/min)

(ms)

㧔r/min 㧕

0

ta

N

(ms)

0

ta

A

c

Nm

(r/min)

0

Nm

Ta 1

TL

N

Time

Time

Motor acceleration

NC command

Motor speed

Motor

acceleration

Motor

torque

Motor actual speed

Motor speed

Speed most required

for the motor torque