1 Introduction

MITSUBISHI CNC

1 - 2

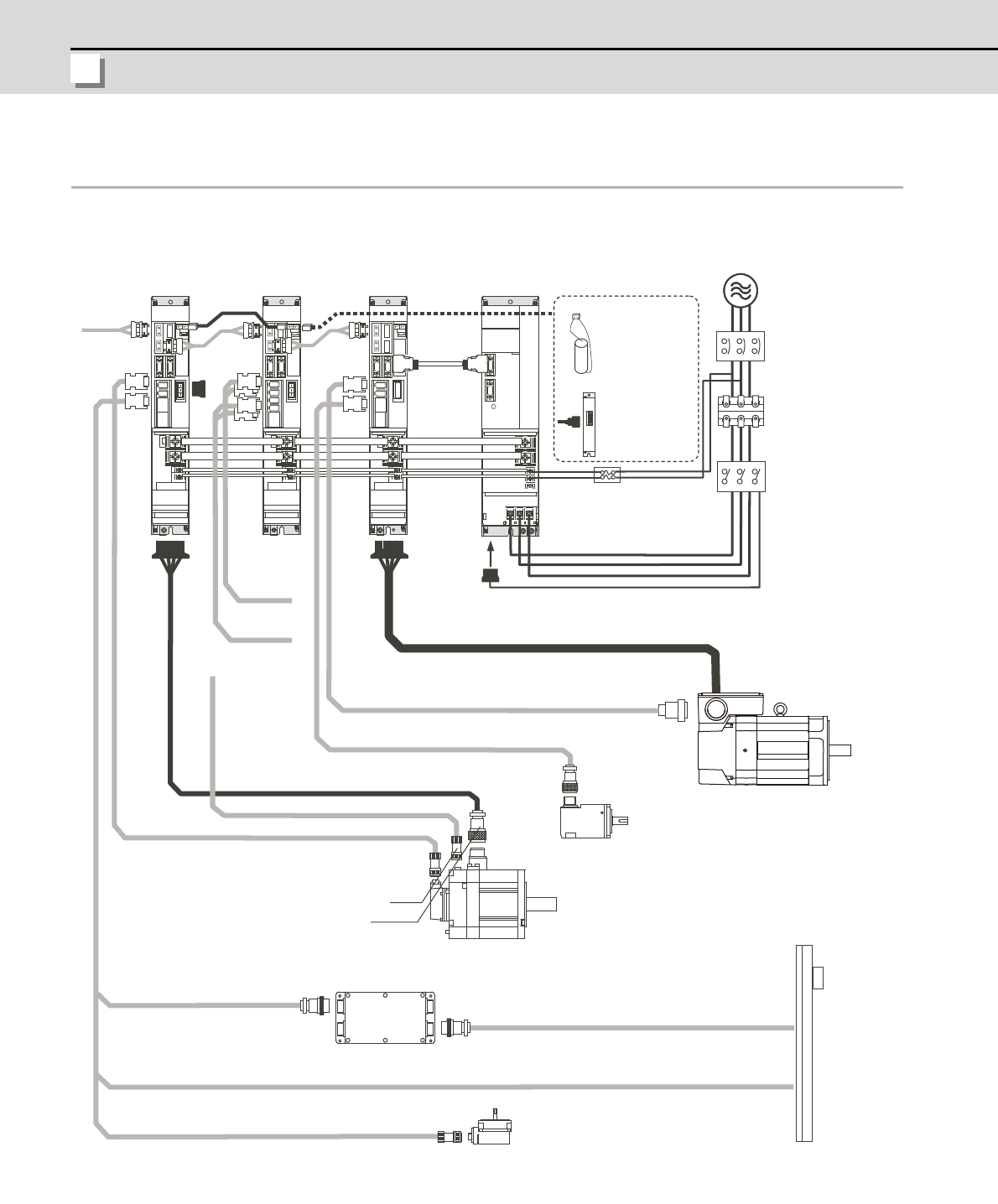

1-1 Servo/spindle drive system configuration

1-1-1 System configuration

CN2L

CN3L

CN2M

CN3M

MDS-D Series:

3-phase 200VAC power supply

MDS-DH Series:

3-phase 400VAC power supply

From NC

1-axis

servo drive unit

(MDS-D/DH-V1)

2-axis

servo drive unit

(MDS-D/DH-V2)

Spindle

drive unit

(MDS-D/DH-SP)

Power supply

unit

(MDS-D/DH-CV)

Built in cell battery

for servo drive unit

or

option battery

CN2

CN2

CN4

CN3

CN3

CN20

1RVKECN

EQOOWPKECVKQP

ECDNG

Brake

connector

Battery cable

Power supply

communication

cable

L+

L-

Power

connector

To 3rd

axis servo

Spindle detector cable

< Motor side PLG cable >

Spindle detector cable

< Spindle side detector cable >

Power cable (Only connector is supplied.)

Brake cable (Only connector is supplied.)

Servo detector cable

< Motor side detector cable >

Brake connector

Power connector

Servomotor

Spindle side detector

Servo detector cable

<MDS-B-HR unit cable >

Servo detector cable

< Linear scale cable> (Note) Prepared by user.

Servo detector cable

< Ball screw side detector cable >

Ball screw side detector

Detector conversion unit

(MDS-B-HR)

Linear scale

(for full closed control)

(Note) Prepared by user.

Servo detector cable

< Linear scale cable for MDS-B-HR >

(Note) Prepared by user.

Spindle motor

Power cable (Only connector is supplied.)

Power supply communication connector

<Connector for contactor control output /

external emergency stop>

Circuit protector or

protection fuse

(Note) Prepared by user.

Contactor

(Note) Prepared

by user.

AC reactor

(D/DH-AL)

Circuit protector

(Note) Prepared

by user.

< Built in cell battery >

<Option battery>

Cell battery built in drive unit

(ER6V-C119B)

Battery unit

(MDS-A-BT)

Battery case

(MDS-BTCASE+A6BAT)

Battery unit

(MDS-BTBOX-36)

1RVKECN

EQOOWPKECVKQP

ECDNG

Power

connector

To brake control

To 2nd

axis servo

ABZ SIN wave signal output

Mitsubishi serial signal output