(4) Usage methods

In abnormal state, install an external emergency stop circuit so that the operation can be stopped and

power shut off immediately.

Turn the power OFF immediately if smoke, abnormal noise or odors are generated from the unit or

motor.

Do not disassemble or repair this product.

Never make modifications.

When an alarm occurs, the machine will start suddenly if an alarm reset (RST) is carried out while an

operation start signal (ST) is being input. Always confirm that the operation signal is OFF before

carrying out an alarm reset. Failure to do so could lead to accidents or injuries.

Reduce magnetic damage by installing a noise filter. The electronic devices used near the unit could be

affected by magnetic noise. Install a line noise filter, etc., if there is a risk of magnetic noise.

Use the unit, motor and regenerative resistor with the designated combination. Failure to do so could

lead to fires or trouble.

The brake (magnetic brake) of the servomotor are for holding, and must not be used for normal braking.

There may be cases when holding is not possible due to the magnetic brake's life, the machine

construction (when ball screw and servomotor are coupled via a timing belt, etc.) or the magnetic

brake's failure. Install a stop device to ensure safety on the machine side.

After changing the programs/parameters or after maintenance and inspection, always test the operation

before starting actual operation.

Do not enter the movable range of the machine during automatic operation. Never place body parts

near or touch the spindle during rotation.

Follow the power supply specification conditions given in each specification for the power (input voltage,

input frequency, tolerable sudden power failure time, etc.).

Set all bits to "0" if they are indicated as not used or empty in the explanation on the bits.

Do not use the dynamic brakes except during the emergency stop. Continued use of the dynamic

brakes could result in brake damage.

If a circuit protector for the main circuit power supply is shared by several units, the circuit protector may

not activate when a short-circuit fault occurs in a small capacity unit. This is dangerous, so never share

the circuit protector.

Mitsubishi spindle motor is dedicated to machine tools. Do not use for other purposes.

(5) Troubleshooting

If a hazardous situation is predicted during power failure or product trouble, use a servomotor with

magnetic brakes or install an external brake mechanism.

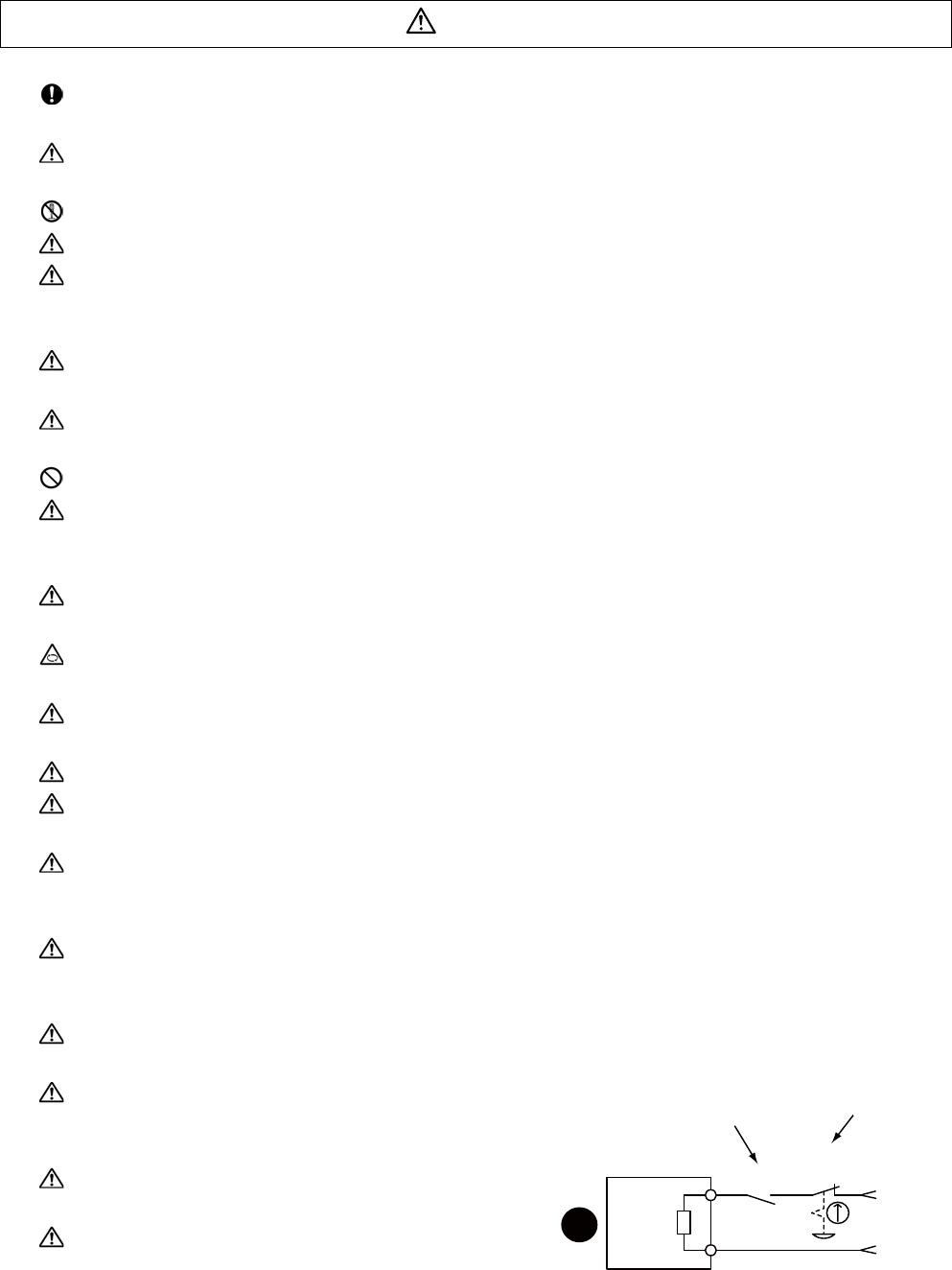

Use a double circuit configuration that allows the

operation circuit for the magnetic brakes to be operated

even by the external emergency stop signal.

Always turn the main circuit power of the motor OFF

when an alarm occurs.

If an alarm occurs, remove the cause, and secure the

safety before resetting the alarm.

CAUTION

MBR

EMG

Servomotor

Magnetic

brake

Shut off with the servomotor

brake control output.

Shut off with NC brake

control PLC output.

24VDC