5 - 27

MDS-D/DH Series Specifications Manual

5-2 Spindle options

5-2-1 Spindle side ABZ pulse output detector (OSE-1024 Series)

When a spindle and motor are connected with a V-belt, or connected with a gear ratio other than 1:1, use this

spindle side detector to detect the position and speed of the spindle. Also use this detector when orientation

control and synchronous tap control, etc are executed under the above conditions.

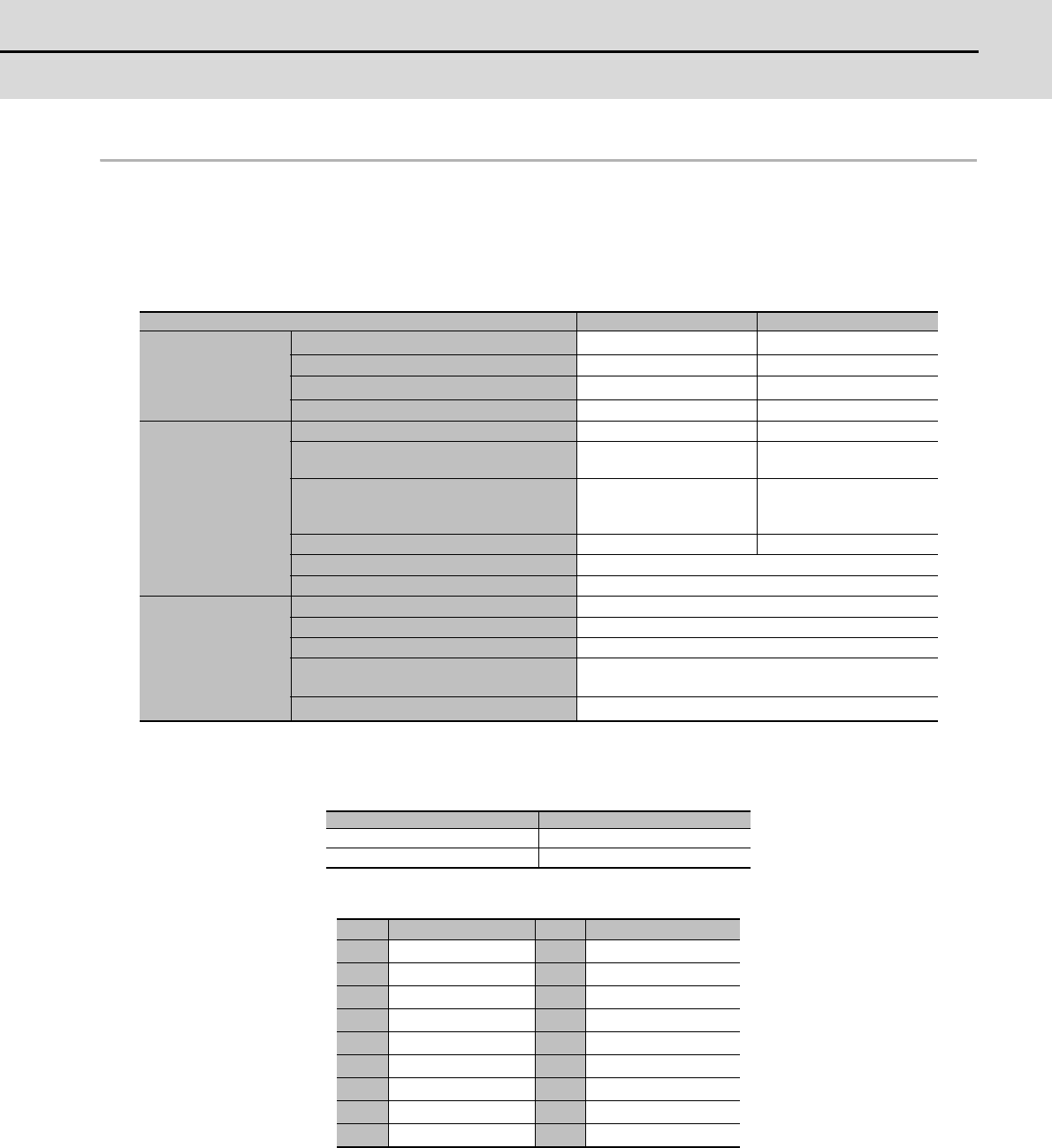

(1) Specifications

(Note) Confirm that the gear ratio (pulley ratio) of the spindle end to the detector is 1:1.

(2) Detection signals

Connector pin layout

Detector type OSE-1024-3-15-68 OSE-1024-3-15-68-8

Mechanical

characteristics for

rotation

Inertia

0.1x10

-4

kgm

2

or less 0.1x10

-4

kgm

2

or less

Shaft friction torque 0.98Nm or less 0.98Nm or less

Shaft angle acceleration

10

4

rad/s

2

or less 10

4

rad/s

2

or less

Tolerable continuous rotation speed 6000 r/min 8000 r/min

Mechanical

configuration

Bearing maximum non-lubrication time 20000h/6000r/min 20000h/8000r/min

Shaft amplitude

(position 15mm from end)

0.02mm or less 0.02mm or less

Tolerable load

(thrust direction/radial direction)

10kg/20kg

Half of value

during operation

10kg/20kg

Half of value

during operation

Mass 1.5kg 1.5kg

Squareness of flange to shaft 0.05mm or less

Flange matching eccentricity 0.05mm or less

Working

environment

Ambient temperature range -5°C to +55°C

Storage temperature range -20°C to +85°C

Humidity 95%Ph

Vibration resistance

5 to 50Hz, total vibration width 1.5mm,

each shaft for 30min.

Impact resistance

294.20m/s

2

(30G)

Signal name Number of detection pulses

A, B phase 1024p/rev

Z phase 1p/rev

Pin Function Pin Function

A A+ signal K 0V

B Z+ signal L -

C B+ signal M -

D - N A- signal

E Case grounding P Z- signal

F - R B- signal

G - S -

H +5V T -

J -