3 - 10

3 Function Specifications

MITSUBISHI CNC

3-2-4 Speed loop PID changeover control

This function is used under full-closed loop control. Normally, machine-end position tracking delays

compared with the motor-end position.

Under full-closed position loop control, machine-end position is used for position feedback. Therefore, the

motor-end position tends to advance too much, which may cause overshooting of the machine-end position.

This function can suppress the generation of overshoot by adding the D (delay) control to the speed control,

which is normally controlled with PI (proportional integral), in order to weaken the PI control after the position

droop becomes 0.

3-2-5 Disturbance torque observer

The effect caused by disturbance, frictional resistance or torsion vibration during cutting can be reduced by

estimating the disturbance torque and compensating it.

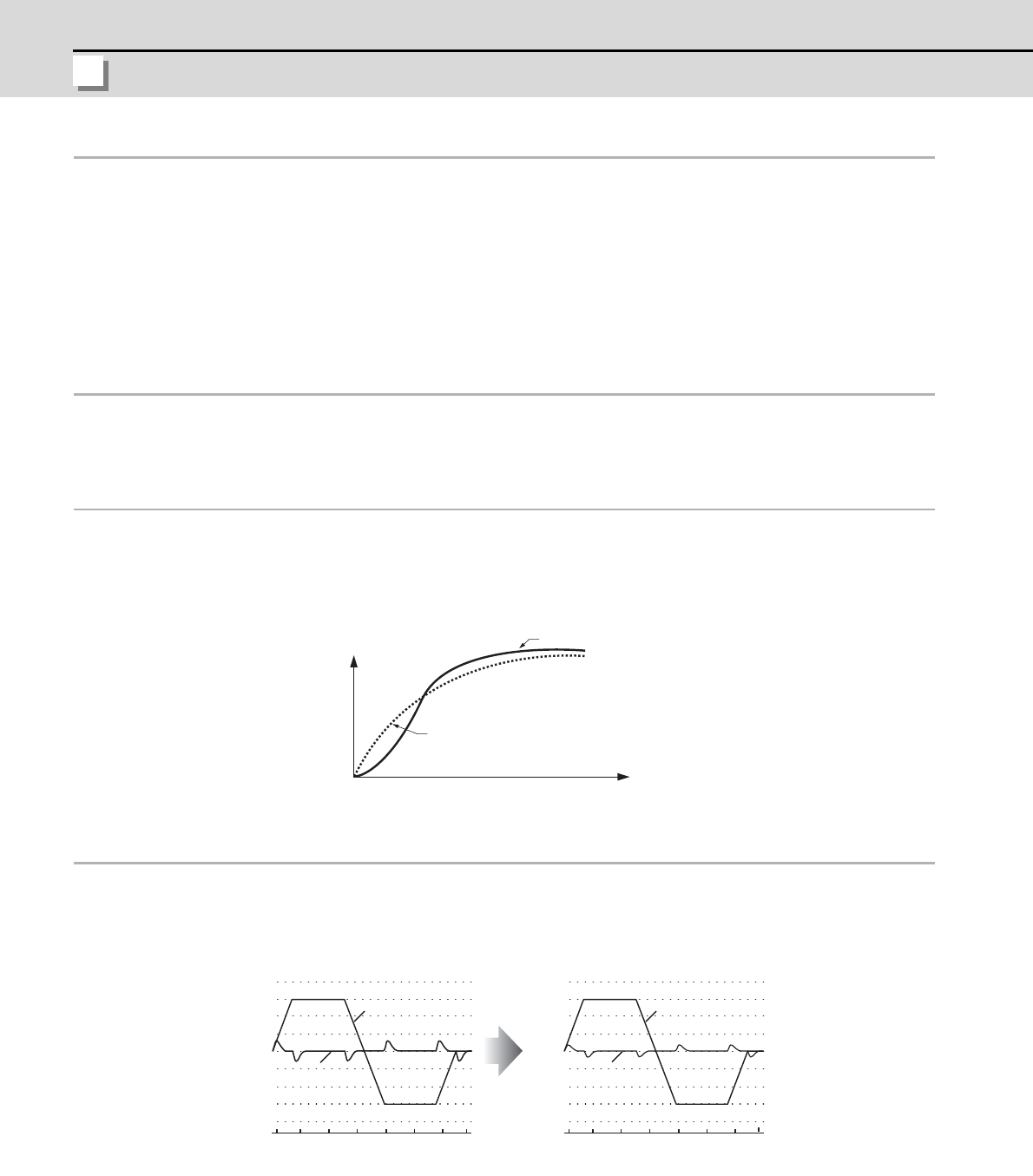

3-2-6 Smooth High Gain control (SHG control)

A high-response control and smooth control (reduced impact on machine) were conventionally conflicting

elements; however, SHG control enables the two elements to function simultaneously by controlling the

motor torque (current FB) with an ideal waveform during acceleration/deceleration.

3-2-7 High-speed synchronous tapping control (OMR-DD control)

Servo drive unit detects the spindle position, and compensates the synchronization errors. This control

enables more accurate tapping than the previous.

SHG control

Speed

Conventional control

Position loop step response

Time

(r/min) (r/min)

Servo/Spindle

synchronous error

(sec) (sec)

Servo/Spindle

synchronous error

With OMR-DD control