3 - 26

3 Function Specifications

MITSUBISHI CNC

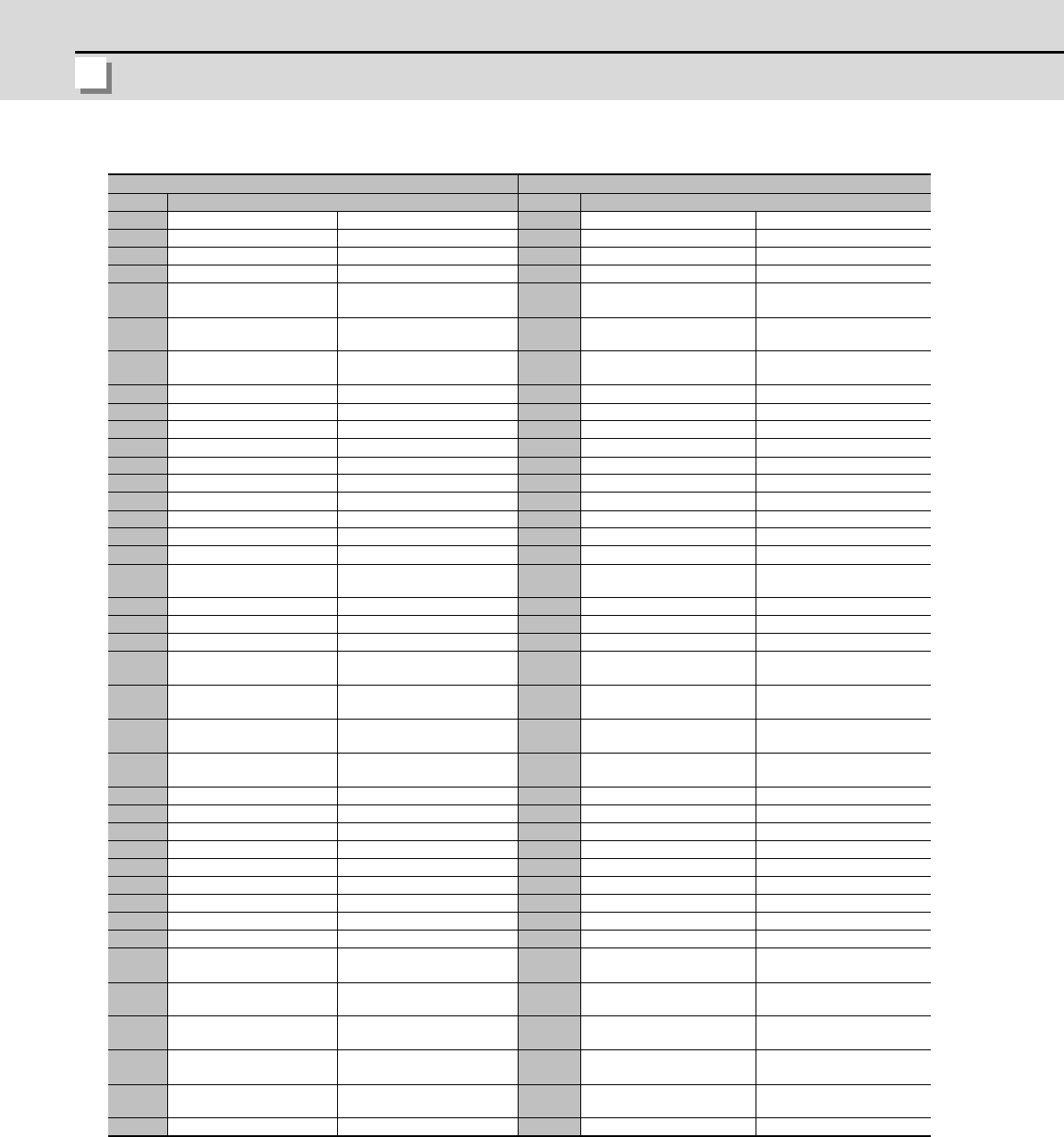

(Spindle control signal)

(Note 1) Control signal is bit output. Setting the No. of the table above to the data output(SP125, SP126),

and when the scale (SP127, SP128) is set to "0", the output is "0V" for bit 0, and "2.5V" for bit 1.

(Note 2) Refer to the section "Spindle control signal" in Instruction Manual for details on the spindle control

signal.

Spindle control input (NC to Spindle) Spindle control output (Spindle to NC)

No. Details No. Details

16384 Spindle control input 1-0 READY ON command 16480 Spindle control output 1-0 In ready ON

16385 Spindle control input 1-1 Servo ON command 16481 Spindle control output 1-1 In servo ON

16391 Spindle control input 1-7 Alarm reset command 16487 Spindle control output 1-7 In alarm

16392 Spindle control input 1-8

Torque limit 1 selection com-

mand

16488 Spindle control output 1-8 In torque limit 1 selection

16393 Spindle control input 1-9

Torque limit 2 selection com-

mand

16489 Spindle control output 1-9 In torque limit 2 selection

16394 Spindle control input 1-A

Torque limit 3 selection com-

mand

16490 Spindle control output 1-A In torque limit 3 selection

16492 Spindle control output 1-C In in-position

16495 Spindle control output 1-F In warning

16496 Spindle control output 2-0 Z phase passed

16499 Spindle control output 2-3 In zero speed

16503 Spindle control output 2-7 In external emergency stop

16409 Spindle control input 2-9

Speed monitor command val-

id

16505 Spindle control output 2-9 In speed monitor

16410 Spindle control input 2-A In door closed (controller) 16506 Spindle control output 2-A In door closed (controller)

16411 Spindle control input 2-B In door closed (all drive units) 16507 Spindle control output 2-B In door closed (self drive unit)

16432 Spindle control input 4-0

Spindle control mode selec-

tion command 1

16528 Spindle control output 4-0

In spindle control mode se-

lection 1

16433 Spindle control input 4-1

Spindle control mode selec-

tion command 2

16529 Spindle control output 4-1

In spindle control mode se-

lection 2

16434 Spindle control input 4-2

Spindle control mode selec-

tion command 3

16530 Spindle control output 4-2

In spindle control mode se-

lection 3

16436 Spindle control input 4-4 Gear changeover command 16532 Spindle control output 4-4

In gear changeover com-

mand

16437 Spindle control input 4-5 Gear selection command 1 16533 Spindle control output 4-5 In gear selection 1

16438 Spindle control input 4-6 Gear selection command 2 16534 Spindle control output 4-6 In gear selection 2

16445 Spindle control input 4-D L coil selection command 16541 Spindle control output 4-D In L coil selection

16545 Spindle control output 5-1 Speed detection

16550 Spindle control output 5-6 In coil changeover

16458 Spindle control input 5-A

Phase synchronization sup-

pression command

16554 Spindle control output 5-A

In phase synchronization

suppression

16459 Spindle control input 5-B

Minimum excitation rate 2

changeover request

16555 Spindle control output 5-B

In minimum excitation rate 2

selection

16460 Spindle control input 5-C

Speed gain set 2 changeover

request

16556 Spindle control output 5-C In speed gain set 2 selection

16461 Spindle control input 5-D

Zero point re-detection re-

quest

16557 Spindle control output 5-D

Zero point re-detection com-

plete

16462 Spindle control input 5-E Spindle holding force up 16558 Spindle control output 5-E

Spindle holding force up

completed

16559 Spindle control output 5-F In 2nd in-position