105

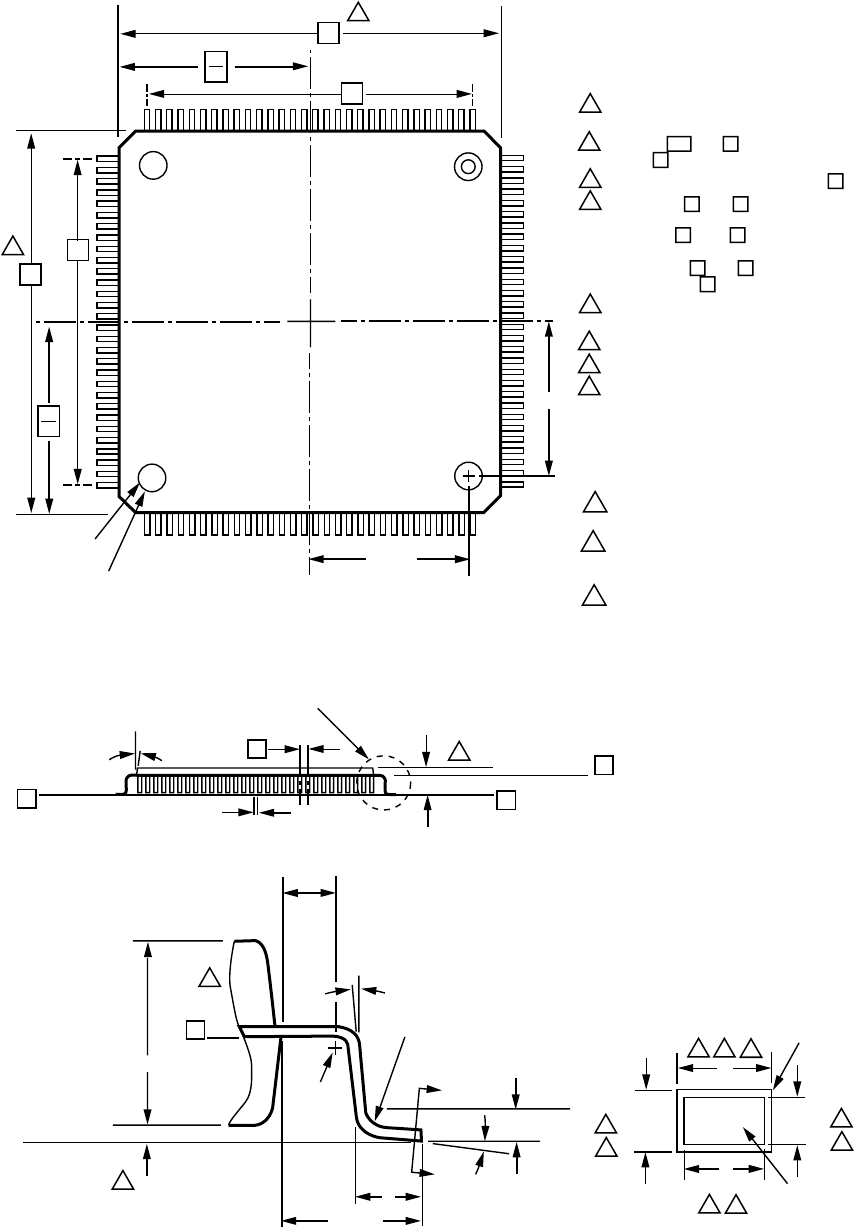

Figure 26. Bottom View of Package

Figure 27. Side View of Package

Figure 28. Detailed View of Pin

12

2

H

L

BASE PLANE

A1

A2

DETAIL "B"

0 - 7°

C

C

0.25

GAGE

PLANE

R 0.13/0.30

0° MIN.

0.40 MIN.

0.13 R

MIN.

1.60 REF.

11

11

9

10

10

11

10

11

10

b

b

1

BASE METAL

SECTION C-C

WITH LEAD FINISH

0.11/0.19

0.11/0.23

DATUM

PLANE

SEATING

PLANE

E1

E2

5

11.0 REF.

11.0 REF.

D2

D1

D1

2

COUNTRY OF

ORIGIN MARK

3.00 REF. DIA.

4 PLACES

BOTTOM VIEW

5

NOTES

1 ALL DIMENSIONS AND TOLERANCES CONFORM TO

ANSI Y145H-1982

2 THE TOP PACKAGE BODY SIZE MAY BE SMALLER THAN

THE BOTTOM PACKAGE BODY SIZE

3 DATUMS A-B AND D TO BE DETERMINED AT DATUM

PLANE H

4 TO BE DETERMINED AT SEATING PLANE C

5 DIMENSION D1 AND E1 DO NOT INCLUDE MOLD

PROTRUSION. ALLOWABLE PROTRUSION IS 0.152 mm

PER SIDE. D1 AND E1 ARE MAXIMUM PLASTIC BODY

SIZE DIMENSIONS INCLUDING MOLD MISMATCH.

DIMENSIONS D1 AND E1 SHALL BE DETERMINED AT

DATUM PLANE H .

6 DETAILS OF PIN 1 IDENTIFIER ARE OPTIONAL, BUT MUST

BE LOCATED WITHIN THE ZONE INDICATED.

7 EXACT SHAPE AT EACH CORNER IS OPTIONAL.

8 MEASURED AT GAGE PLANE.

9 DIMENSION b DOES NOT INCLUDE DAMBAR

PROTRUSION, ALLOWABLE PROTRUSION SHALL BE

0.08 mm TOTAL IN EXCESS OF THE b DIMENSION AT

MAXIMUM MATERIAL CONDITION . DAMBAR MAY NOT

BE LOCATED AT THE LOWER RADIUS OF THE FOOT. THE

MINIMUM SPACING BETWEEN PROTRUSION AND AN

ADJACENT LEAD SHALL NOT BE LESS THAN 0.07 mm.

10 PLATING THICKNESS 0.007 MIN. TO 0.020 MAX. SOLDER

PLATE 855n/ISPO.

11 THESE DIMENSIONS APPLY TO THE FLAT SECTION OF

THE LEAD BETWEEN 0.10 mm AND 0.25 mm FROM THE

LEAD TIP.

12 A1 IS DEFINED AS THE DISTANCE FROM THE SEATING

PLANE TO THE LOWEST POINT OF THE PACKAGE BODY.

E1

2

2

e

C

12° - 16°

SEE DETAIL "B"

A

b

SEATING

PLANE

C

H

DATUM PLANE

ccc