Emerson Process Management GmbH & Co. OHG3-2

X-STREAM XE

Instruction Manual

HASXEE-IM-HS

04/2010

3.1 Infrared (IR) and Ultraviolet (UV) Measurement

lution frequency. As a result, the proof peak

process is integrated into the measurement

information, in contrast to being articially

inserted in the measurement signal.

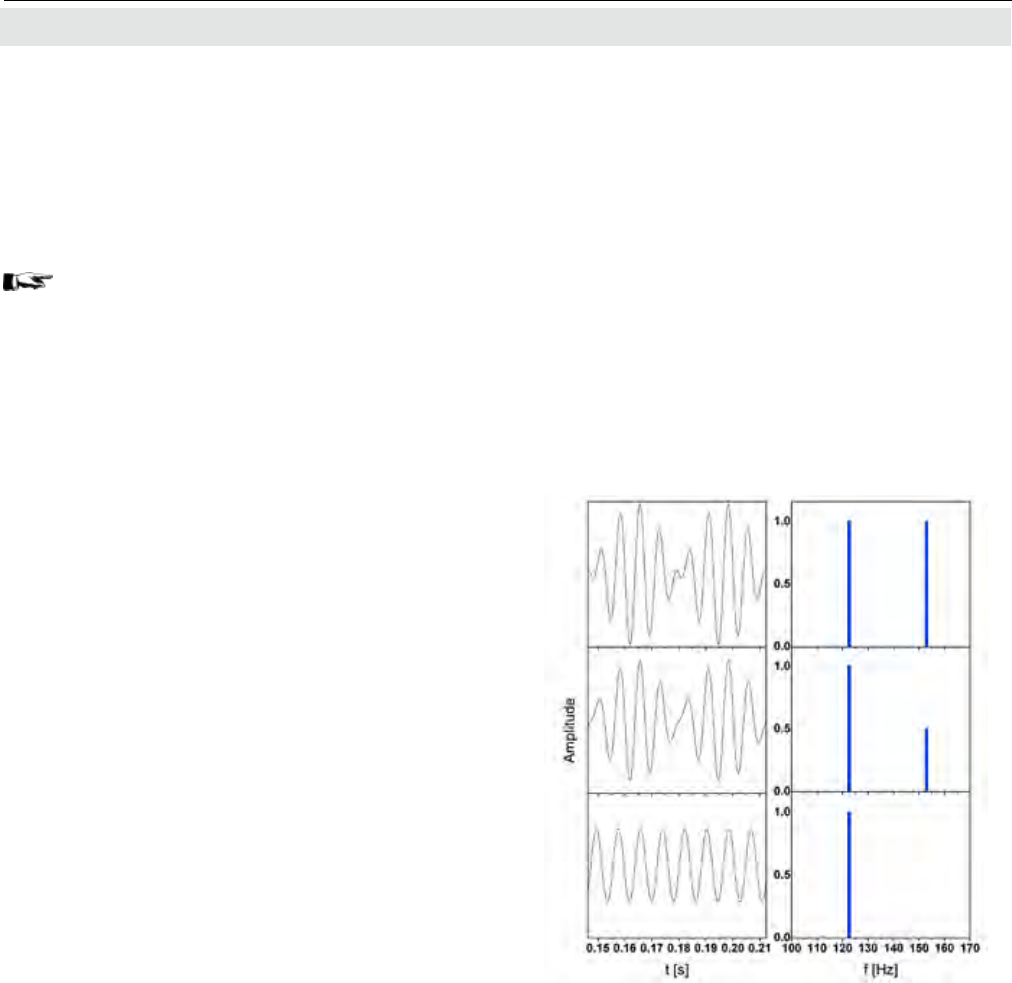

Frequency ltering separates the sum signal

into measurement and reference signal (

Fig. 3-1). This results in a permanently

referenced signal by dividing the integrated

reference level by the integrated measure-

ment level for each revolution.

Therefore the IntrinzX technology provides

many outstanding features:

• High dynamic measurement ranges (e.g.

0-200 to 50,000 ppm CO), which cannot

be obtained with standard photometric

technologies

• Reduced temperature dependency

• High sensitivity for lowest measuring

ranges

This leads to cost saving effects for the cu-

stomer:

• Fewer number of benches & cells

• Easier eld repair and replacement of

parts

• Easy adjustment of low measuring ranges

in the eld

• Reduced maintenance

• Extended span calibration intervals

• Minimized demand for test gases

Due to the inherent correlation between refe-

rence and measurement side, span calibration

can often be achieved by zero calibration.

The above listed IntrinzX features offer a

high degree of exibility with regards to ap-

plications:

• One bench enables measurements of low

& high ranges

• Low & high concentration in raw and clean

gases

• Small and large ranges before and after

scrubbers

• Measurement of carbon bed breakthrough /

catalyst efciency

• Mobile measurements at different samp-

ling points / locations

• Easy adaption to different applications

(universities, laboratories)

• Supports automotive engine testing

• Benches to be used in TOC applications

for measurements of low and high carbon

content

Fig. 3-1: IntrinzX Signal Forms

0 % absorption50 % absorption100 % absorption