Programming and Operating Concepts

Video Recorder – User Manual 60

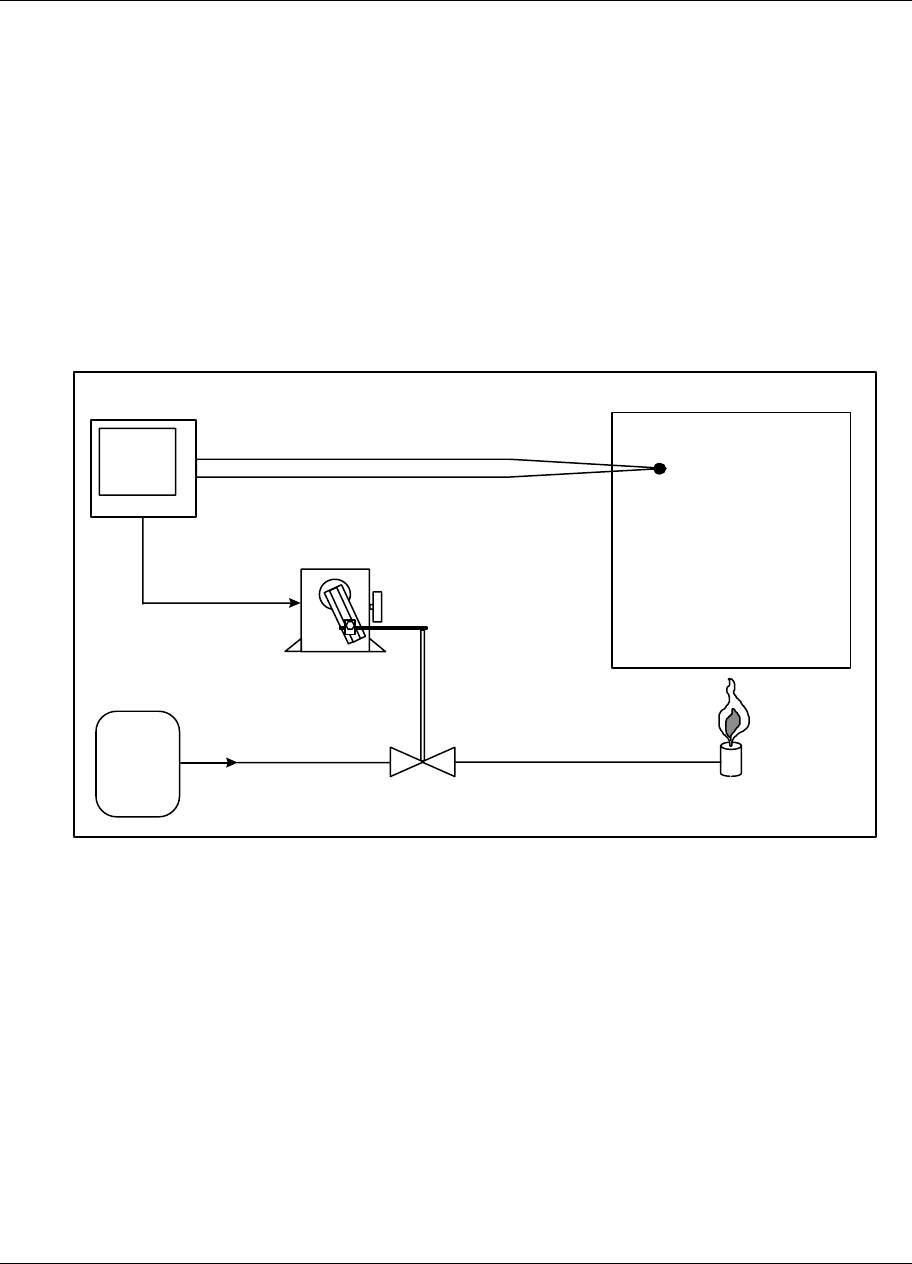

3.14 How to program common configurations

Being able to diagram a control configuration in terms of function blocks makes it easier to program and

configure your instrument for its intended process control application. This function block diagram you

create can be used as a “construction blue print” to program the instrument. Each block in the diagram

relates to a dedicated instrument programming menu in the instrument’s PROGRAM mode.

What follows are examples where common control configurations are presented along with their function

block diagrams. The first example is a simple control arrangement in great detail to help you understand

function block diagram basics, followed by more sophisticated examples. Once you understand how to

diagram function blocks, you will be able to draw a diagram for virtually any control strategy regardless of

complexity. Understanding the relationship between such diagrams and the instrument’s programming

menus is key to successfully mastering the instrument’s many capabilities and features.

Programming a Current Driven Heat Treat Element

An example of one of the most common and simple control strategies is in Figure 3-11 below.

GAS

SUPPLY

VALVE

BURNER

FURNACE ZONE

TYPE J THERMOCOUPLE

VALVE

ACTUATOR

4 TO 20 mA

(CAT)

PV 200

SP 500

OUT 83.5%

INSTRUMENT

Figure 3-11 Control Of Furnace Zone Temperature With 4-20 mA (CAT) Control Signal