Model 9110T NOx Analyzer Principles of Operation

Teledyne Analytical Instruments 322

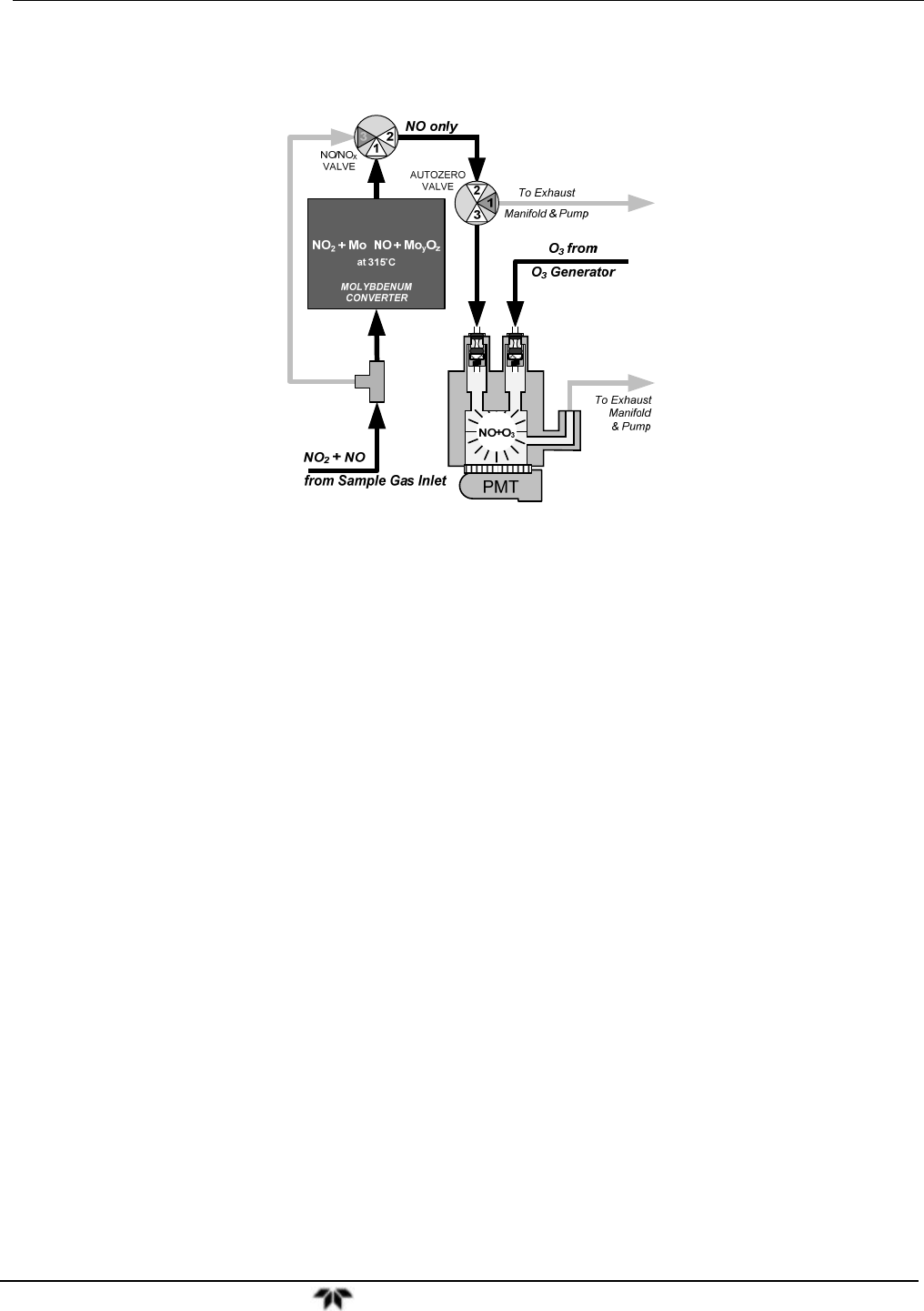

In order to measure the concentration of NO

2

, and therefore the concentration of NO

x

, the 9110T

periodically switches the sample gas stream so that the pump pulls it through a special converter

cartridge filled with molybdenum (Mo, “moly”) chips that are heated to a temperature of 315°C.

NO only

Figure 13-3: NO

2

NO Conversion

The heated molybdenum reacts with NO

2

in the sample gas and produces a NO gas and a variety of

molybdenum.

Equation 13-4

)315(

2

CatOMxNOyMoxNO

zy

Once the NO

2

in the sample gas has been converted to NO, it is routed to the reaction cell where it

undergoes the chemiluminescence reaction described in Equation 13-1 and Equation 13-2.

By converting the NO

2

in the sample gas into NO, the analyzer can measure the total NO

X

) content of

the sample gas (i.e. the NO present + the converted NO

2

present). By switching the sample gas stream

in and out of the “moly” converter every 6 - 10 seconds, the 9110T analyzer is able to quasi-

continuously measure both the NO and the total NO

X

content.

Finally, the NO

2

concentration is not directly measured but calculated by subtracting the known NO

content of the sample gas from the known NO

X

content.

13.1.4. AUTO ZERO

Inherent in the operation of any PMT is a certain amount of noise. This is due to a variety of factors

such as black body infrared radiation given off by the metal components of the reaction cell, unit to unit

variations in the PMT units and even the constant universal background radiation that surrounds us at all

times. In order to reduce this amount of noise and offset, the PMT is kept at a constant 7° C (45° F) by a

Thermo-Electric Cooler (TEC).

While this intrinsic noise and offset is significantly reduced by cooling the PMT, it is not eradicated. To

determine how much noise remains, once every minute for about 8 seconds the 9110T diverts the sample

gas flow directly to the vacuum manifold without passing the reaction cell.