Model 9110T NOx Analyzer Principles of Operation

Teledyne Analytical Instruments 331

The actual flow rate of gas through the orifice (volume of gas per unit of time), depends on the size and

shape of the aperture in the orifice. The larger the hole, the more gas molecules (moving at the speed of

sound) pass through the orifice.

In addition to controlling the gas flow rates into the reaction cell, the two critical flow orifices at the

inlets of the reaction cell also maintain an under-pressure inside it, effectively reducing the number of

molecules in the chamber and the corresponding incidence of third body quenching (see Section

13.1.5.2) and therefore increasing the chemiluminescence yield.

The 9110T reaches its peak sensitivity at about 2 in-Hg-A, below which the sensitivity drops due to

there being too few molecules present and a corresponding decrease in chemiluminescence.

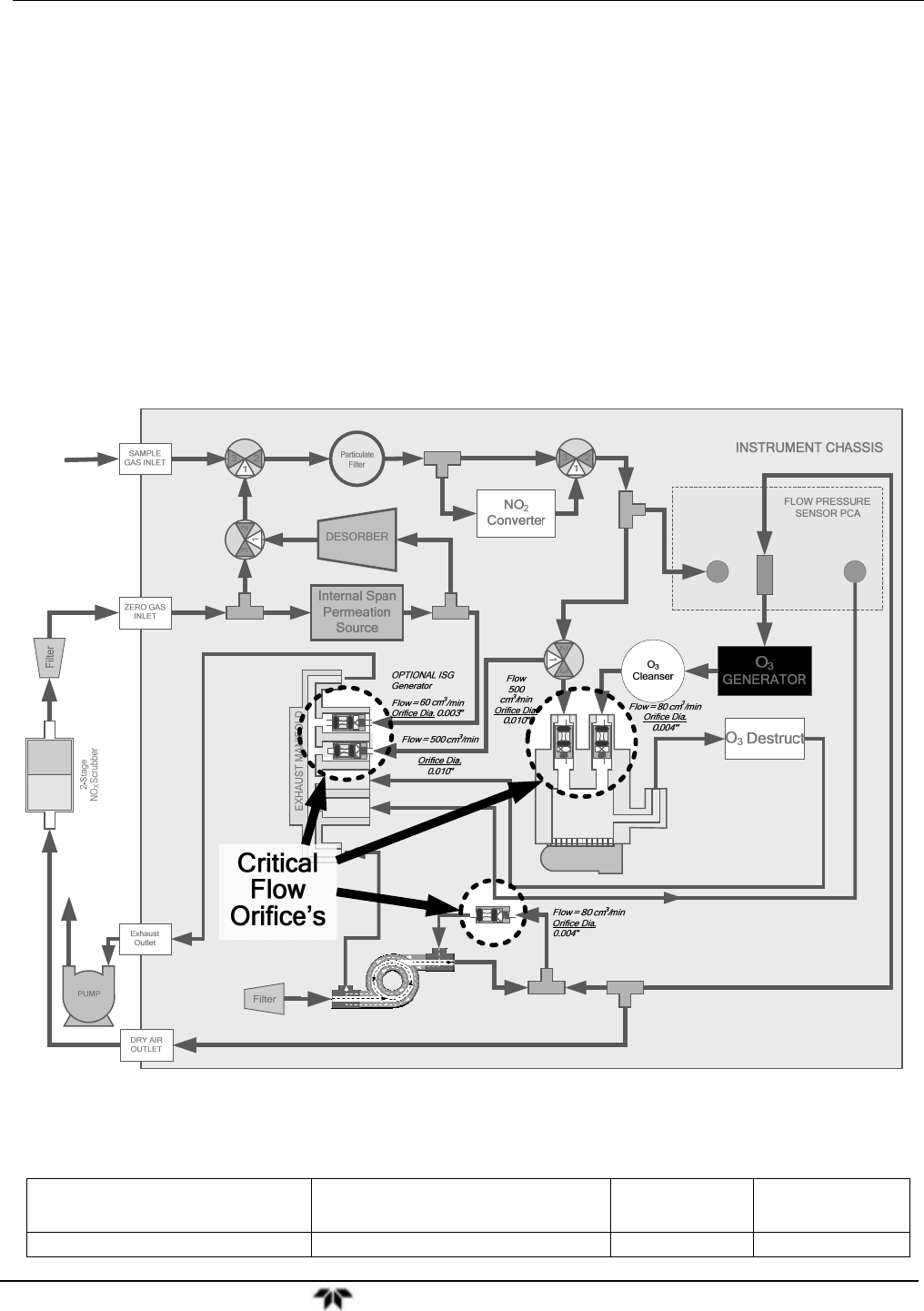

13.2.2.2. Locations and Descriptions of Critical Flow Orifices Inside the 9110T

The 9110T uses several of the following critical flow orifices (Figure 13-9) to create and maintain the

proper flow rate of gas through its various components. (Please note that not all features displayed in

Figure 13-9 are standard components of 9110T analyzers).

SAMPLE

PRESSURE

SENSOR

VACUUM

PRESSURE

SENSOR

O

3

FLOW

SENSOR

PMT

PERMAPURE

DRYER

NO/NO

X

VALVE

AUTOZERO

VALVE

SAMPLE/ CAL

VALVE

ZERO/SPAN

VALVE

Figure 13-9: Location of Flow Control Assemblies & Critical Flow Orifices

Table 13-3: 9110T Gas Flow Rates

Location Purpose

Orifice

Diameter

Flow rate

(nominal)

Sample gas inlet of reaction cell

Controls rate of flow of sample gas into the

0.010” (0.25 mm) 500 cm³/min