Model 9110T NOx Analyzer Principles of Operation

Teledyne Analytical Instruments 329

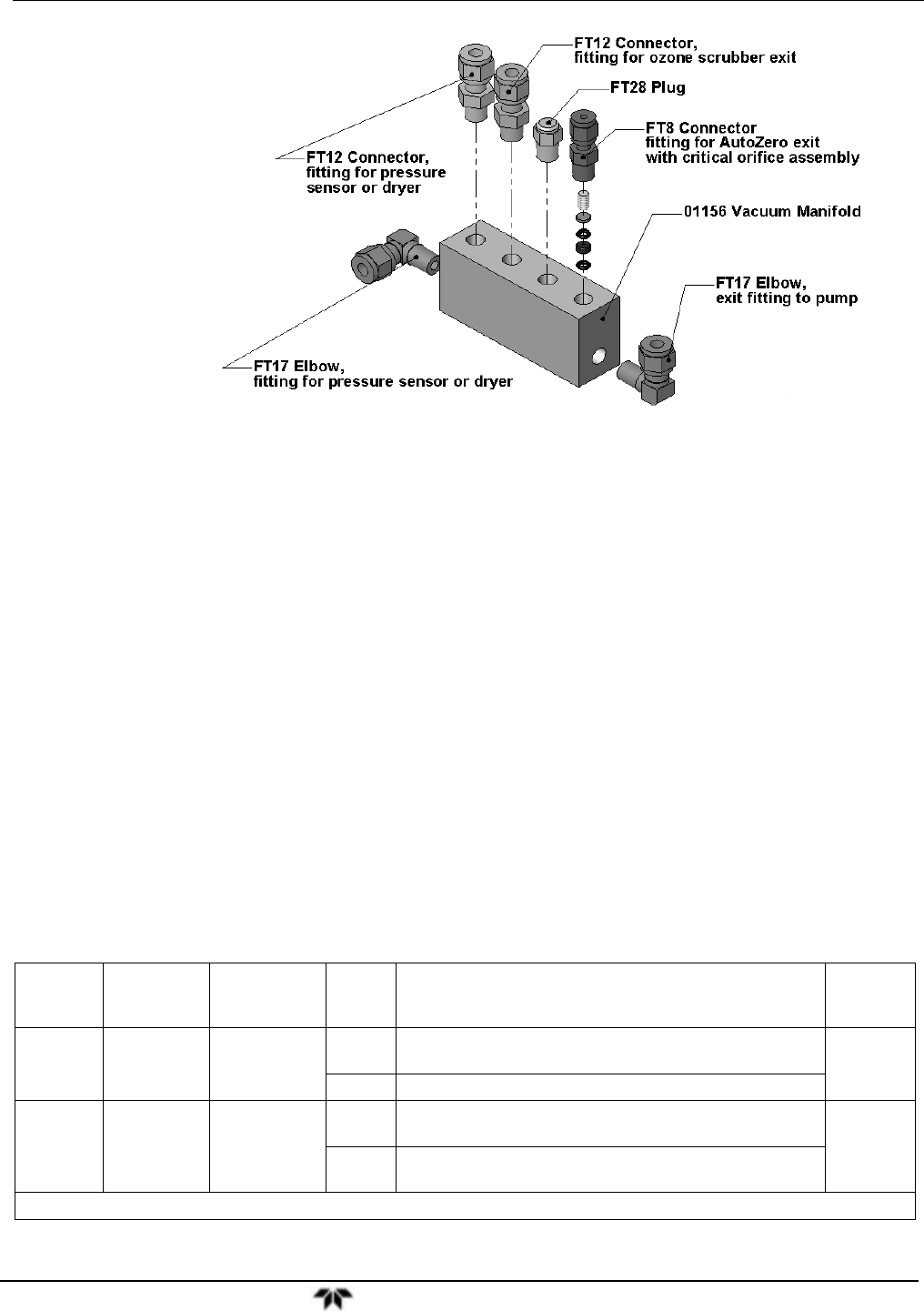

Figure 13-7. Vacuum Manifold, Standard Configuration

Configurations will vary depending on the optional equipment that is installed. For example:

An 9110T with the optional internal span gas generator installed will add another FT8 connector and

orifice assembly to the manifold where the FT28 fitting is shown in the above drawing.

An optional sample gas dryer will add a Tee-fitting so that two ¼” tubes can be connected to the

same port.

13.2.1.2. Sample Gas Flow Valves and Routing

As discussed in Section 13.1, the measurement of NO

x

, NO and NO

2

requires that the sample gas flow

cycles through different routes that include and exclude various scrubbers and converters. There are

several valves that perform this function:

The NO/NO

X

valve directs the sample gas either directly to the reaction cell or through the unit’s

NO

2

converter, alternating every ~8 sec.

The Auto Zero valve directs the sample gas stream to completely bypass the reaction cell for dark

noise measurement once every minute, which is then subtracted as a measurement offset from the

raw concentration signal.

Table 13-2: 9110T Valve Cycle Phases

Phase

NO/ NO

X

Valve

Status

Auto Zero

Valve

Status

Time

Index

Activity Figure

NO

Measure

Open to

Auto Zero

valve

Open to

reaction cell

0 - 2 s

Wait period (NO dwell time). Ensures reaction cell has

been flushed of previous gas.

Figure

13-3

2 - 4 s Analyzer measures chemiluminescence in reaction cell.

NO

X

Measure

Open to

NO

2

converter

Open to

reaction cell

4 – 6 s

Wait period (NO

X

dwell time). Ensures reaction cell has

been flushed of previous gas.

Figure

13-3

6 – 8 s

Analyzer measures NO + O

3

chemiluminescence in

reaction cell.

Cycle repeats every ~8 seconds