9 PID CONTROL FUNCTION

9.4 Relationship Between Parameter Setting and Auto-Tuning

57

9

■Set item

■Precautions for using the PID instruction

For the precautions for using the PID instruction, refer to the following manual.

MELSEC iQ-F FX5 Programming Manual (Instructions, Standard Functions/Function Blocks)

9.4 Relationship Between Parameter Setting and

Auto-Tuning

When auto-tuning is not executed (parameter setting)

It is necessary to write the set value of the parameters (s3) to (s3)+6 using MOV instruction in advance, etc. before starting

the PID operation when auto-tuning is not executed. If a device with a latch setting is specified, the setting data is retained

even after the power to the CPU module is turned OFF; therefore, the writing at the 2nd power ON is not required.

For details on parameters, refer to Page 58 Parameter.

When auto-tuning is executed

The proportional gain ((s3)+3), integral time ((s3)+4) and differential time ((s3)+6) are important constants for executing the

auto-tuning function described later and for optimizing the PID control. These constants can be set automatically.

For a detailed description of auto-tuning, refer to Page 68 Auto-Tuning.

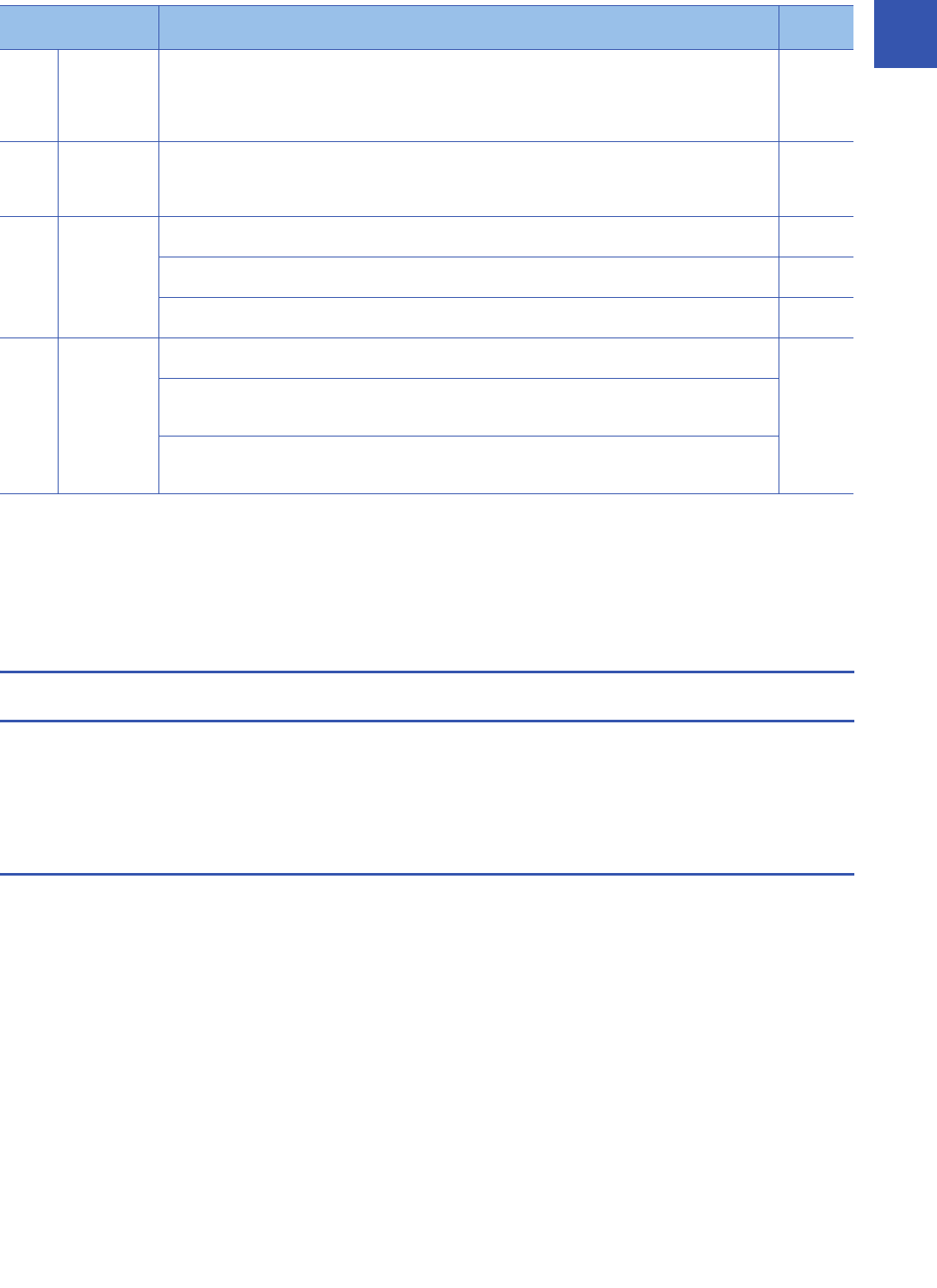

Set item Description Occupie

d points

(s1) Target value

(SV)

The target value (SV) is set.

The PID instruction does not change the settings.

[Caution on using the auto-tuning (limit cycle method)]

If the target value for auto-tuning is different from the target value in the PID control, it is necessary to set a value

to which a bias value is added, and then store the actual target value when the auto-tuning flag turns OFF.

1 point

(s2) Measured value

(PV)

This is the input value of the PID operation.

It is necessary to read a normal measurement data before the execution of the PID operation for the measurement

value of PID (PV). If an input value from an analog input is used for the PID operation, use caution to its conversion

time.

1 point

(s3) Parameter PID control

25 devices are occupied from the head device specified in (s3)

25 points

Auto-tuning: In the limit cycle (1)

29 devices are occupied from the head device specified in (s3)

29 points

Auto-tuning: In the step response method (2)

25 devices are occupied from the head device specified in (s3)

25 points

(d) Output value

(MV)

PID control (normal processing)

The user sets the initial output value before driving the instruction. After that, the operation result is stored.

1 point

Auto-tuning: In the limit cycle

The Upper Limit Value (ULV) or Lower Limit Value (LLV) value is automatically output during auto-tuning. The

specified MV value is output when auto-tuning is finished.

Auto-tuning: In the step response method

The user sets the step output value before driving the instruction. The MV value is not changed by PID instruction

during auto-tuning.