EPA Protocol Calibration Teledyne API – T101 Operation Manual

188

time. Therefore, it is necessary to dynamically check the calibration relationship on a

predetermined schedule. Zero and span checks must be used to document that the data

remains within control limits. These checks are also used in data reduction and validation.

Table 7-3 summarizes the initial quality assurance activities for calibrating equipment.

Table 7-2 is a matrix for the actual dynamic calibration procedure.

Calibrations should be carried out at the field monitoring site. The Analyzer should be in

operation for at least several hours (preferably overnight) before calibration so that it is

fully warmed up and its operation has stabilized. During the calibration, the T101 should

be in the CAL mode, and therefore sample the test atmosphere through all components

used during normal ambient sampling and through as much of the ambient air inlet

system as is practicable. If the Instrument will be used on more than one range (i.e. IND

or AUTO ranges), it should be calibrated separately on each applicable range. Calibration

documentation should be maintained with each analyzer and also in a central backup file.

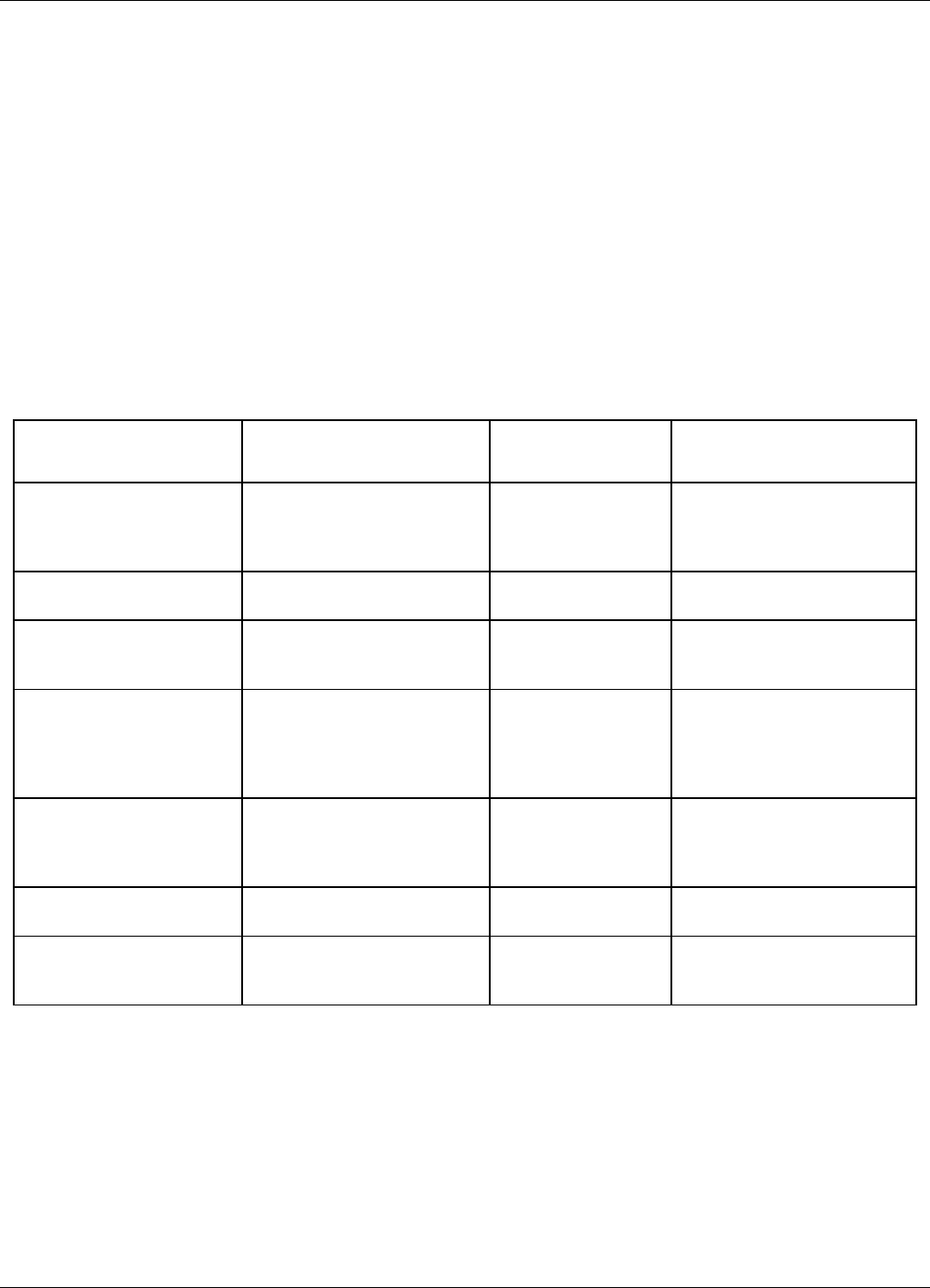

Table 7-1. Activity Matrix for Calibration Equipment & Supplies

EQUIPMENT/SUPPLIES ACCEPTANCE LIMITS

FREQUENCY AND

METHOD OF

MEASUREMENT

ACTION IF REQUIREMENTS

ARE NOT MET

Recorder Compatible with output

signal of analyzer; min.

chart width of 150 mm (6

in) is recommended

Check upon receipt Return equipment to

supplier

Sample Line And Manifold Constructed of PTFE or

glass

Check upon receipt Return equipment to

supplier

Calibration Equipment Meets guidelines of

reference 1 and Section

2.3.2 (Q.A. Handbook)

See Section 2.3.9

(Q.A. Handbook)

Return equipment/ supplies

to supplier or take

corrective action

Working Standard SO

2

Cylinder Gas Or SO

2

Permeation Tube

Traceable to NIST-SRM

meets limits in traceability

protocol for accuracy and

stability (Section 2.0.7,

Q.A. Handbook)

Analyzed against

NIST-SRM; see

protocol in Section

2.0.7, Q.A.

Handbook

Obtain new working

standard and check for

traceability

Zero Air Clean dry ambient air, free

of contaminants that cause

detectable response with

the SO

2

analyzer.

See Section 2.9.2

(Q.A. Handbook)

Obtain air from another

source or regenerate.

Record Form Develop standard forms N/A Revise forms as

appropriate

Audit Equipment Must not be the same as

used for calibration

System must be

checked out against

known standards

Locate problem and correct

or return to supplier

07266B DCN6485