Troubleshooting & Service Model T101 Instruction Manual

216

9.1.2. FAULT DIAGNOSIS WITH TEST FUNCTIONS

Besides being useful as predictive diagnostic tools, the TEST functions, viewable from

the front panel, can be used to isolate and identify many operational problems when

combined with a thorough understanding of the analyzer’s theory of operation (Section

10). We recommend use of the APICOM remote control program to download, graph

and archive TEST data for analys

is, and long-term monitoring of diagnostic data.

The acceptable ranges for these test functions are listed in Table A-3 in Appendix A-3.

The actual values for these test functions on checkout at the factory were also listed in

the Final Test and Validation Data Sheet, which was shipped with the instrument.

Values outside the acceptable ranges indicate a failure of one or more of the analyzer’s

subsystems. Functions with values that are within the acceptable range but have

significantly changed from the measurements recorded on the factory data sheet may

also indicate a failure or a maintenance item. A problem report worksheet has been

provided in Appendix C to assist in recording the value of these test functions. The

following table (Table 9-2) contains some of the more common causes for these values

to be out of range.

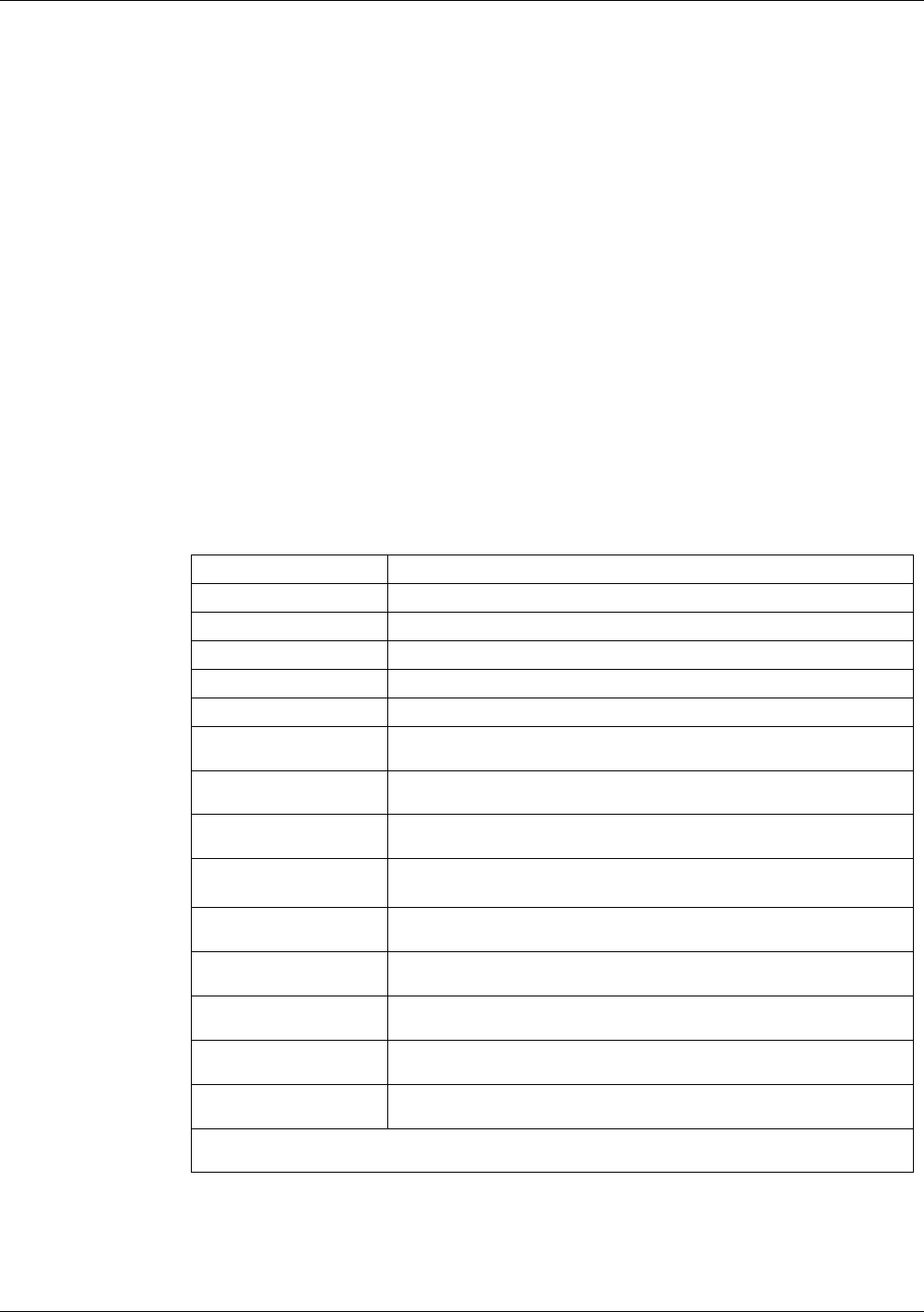

Table 9-2. Test Functions - Possible Causes for Out-Of-Range Values

TEST FUNCTION INDICATED FAILURE(S)

H2S STB

1

Unstable concentrations; leaks

SAMPLE FL

Leaks; clogged critical flow orifice

PMT

Calibration error; HVPS problem; PMT problem; No flow (leaks)

NORM PMT

Calibration error; HVPS problem; PMT problem

HVPS

HVPS broken; preamp board circuit problems

RCELL TEMP

Malfunctioning heater; relay board communication (I

2

C bus); relay

burnt out

BOX TEMP

Environment out of temperature operating range; broken

thermistor; runaway heater

PMT TEMP

TEC cooling circuit broken; High chassis temperature; 12V power

supply

IZS TEMP

(OPTION)

Malfunctioning heater; relay board communication (I

2

C bus); relay

burnt out

CONV TEMP

Malfunctioning heater or temperature sensor; relay board

communication (I

2

C bus); relay burnt out

PRESS

Leak; malfunctioning valve; malfunctioning pump; clogged flow

orifices; sample inlet overpressure;

H2S SLOPE

1

Calibration error; span gas concentration incorrect; leaks; low lamp

output

H2S OFFS

1

Incorrect span gas concentration/contaminated zero air/leak; low-

level calibration off

TIME OF DAY

Internal clock drifting; move across time zones; daylight savings

time?

1

Shown as they appear when analyzer is in H

2

S mode. In SO

2

mode appear as SO2 STB,

SO2 OFFS & SO2 SLOPE. In multigas mode, both versions appear.

07266B DCN6485