Principles Of Operation Model T101 Instruction Manual

256

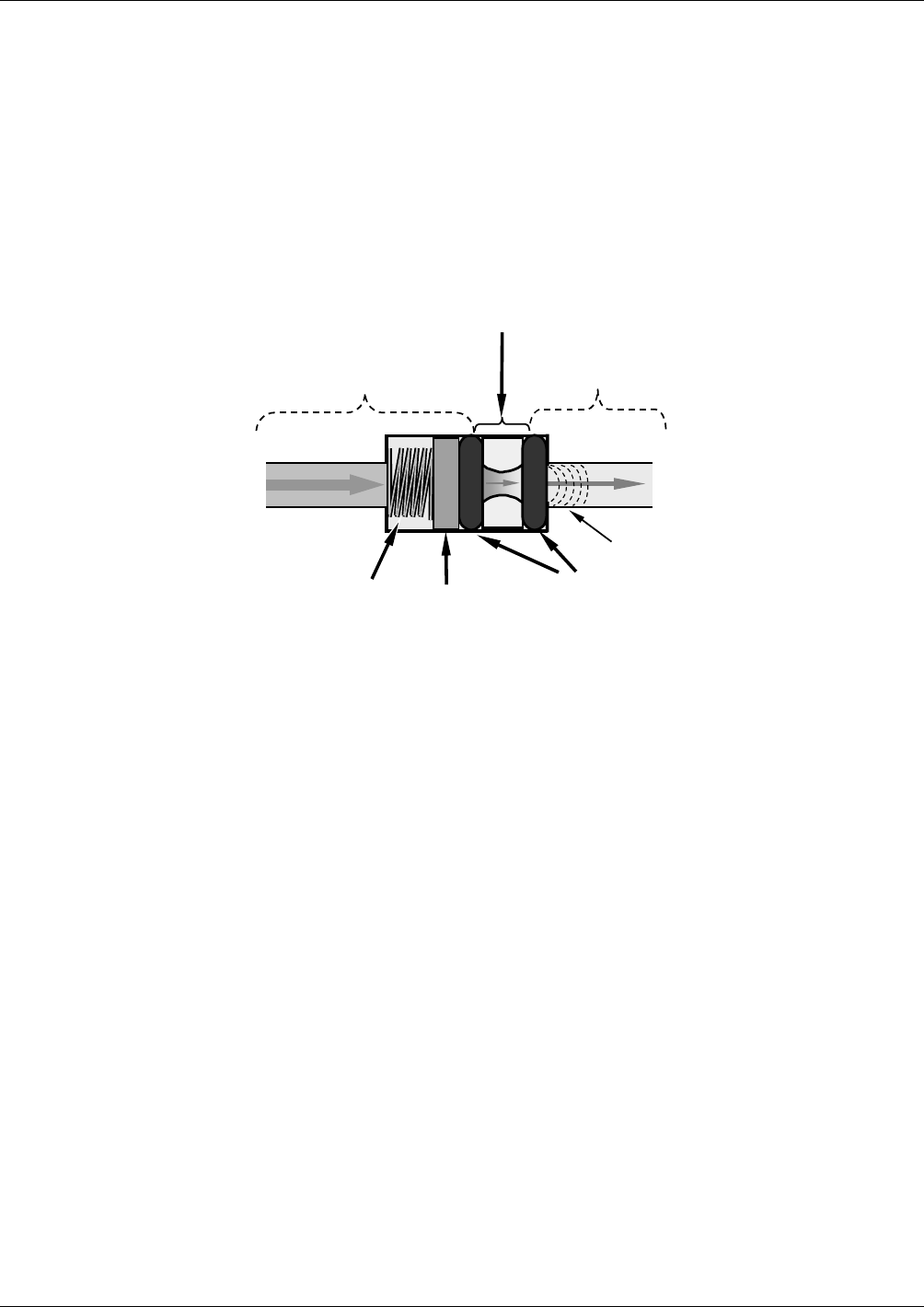

pressure differential combined with the action of the analyzer’s external pump draws the

gas through the orifice.

As the pressure on the downstream side of the orifice (the pump side) continues to drop,

the speed that the gas flows though the orifice continues to rise. Once the ratio of

upstream pressure to downstream pressure is greater than 2:1, the velocity of the gas

through the orifice reaches the speed of sound. As long as that ratio stays at least 2:1 the

gas flow rate is unaffected by any fluctuations, surges, or changes in downstream

pressure because such variations only travel at the speed of sound themselves and are

therefore cancelled out by the sonic shockwave at the downstream exit of the critical

flow orifice.

SPRING

O-RINGS

FILTER

CRITICAL

FLOW

ORIFICE

A

REA OF

LOW

PRESSURE

AREA OF

HIGH

PRESSURE

Sonic

Shockwave

Figure 10-8. Typical Flow Control Assembly with Critical Flow Orifice

The actual flow rate of gas through the orifice (volume of gas per unit of time), depends

on the size and shape of the aperture in the orifice. The larger the hole, the more gas

molecules, moving at the speed of sound, pass through the orifice.

The result is that he flow rate of the gas is unaffected by degradations in pump

efficiency due to age.

The critical flow orifice used in the Model T101 is designed to provide a flow rate of

600 cm3/min.

10.3.4. SAMPLE PARTICULATE FILTER

To remove particles in the sample gas, the analyzer is equipped with a Teflon membrane

filter of 47 mm diameter (also referred to as the sample filter) with a 1 µm pore size. The

filter is accessible through the front panel, which folds down, and should be changed

according to the suggested maintenance schedule in Table 9-1.

07266B DCN6485