EPA Protocol Calibration Teledyne API – T101 Operation Manual

192

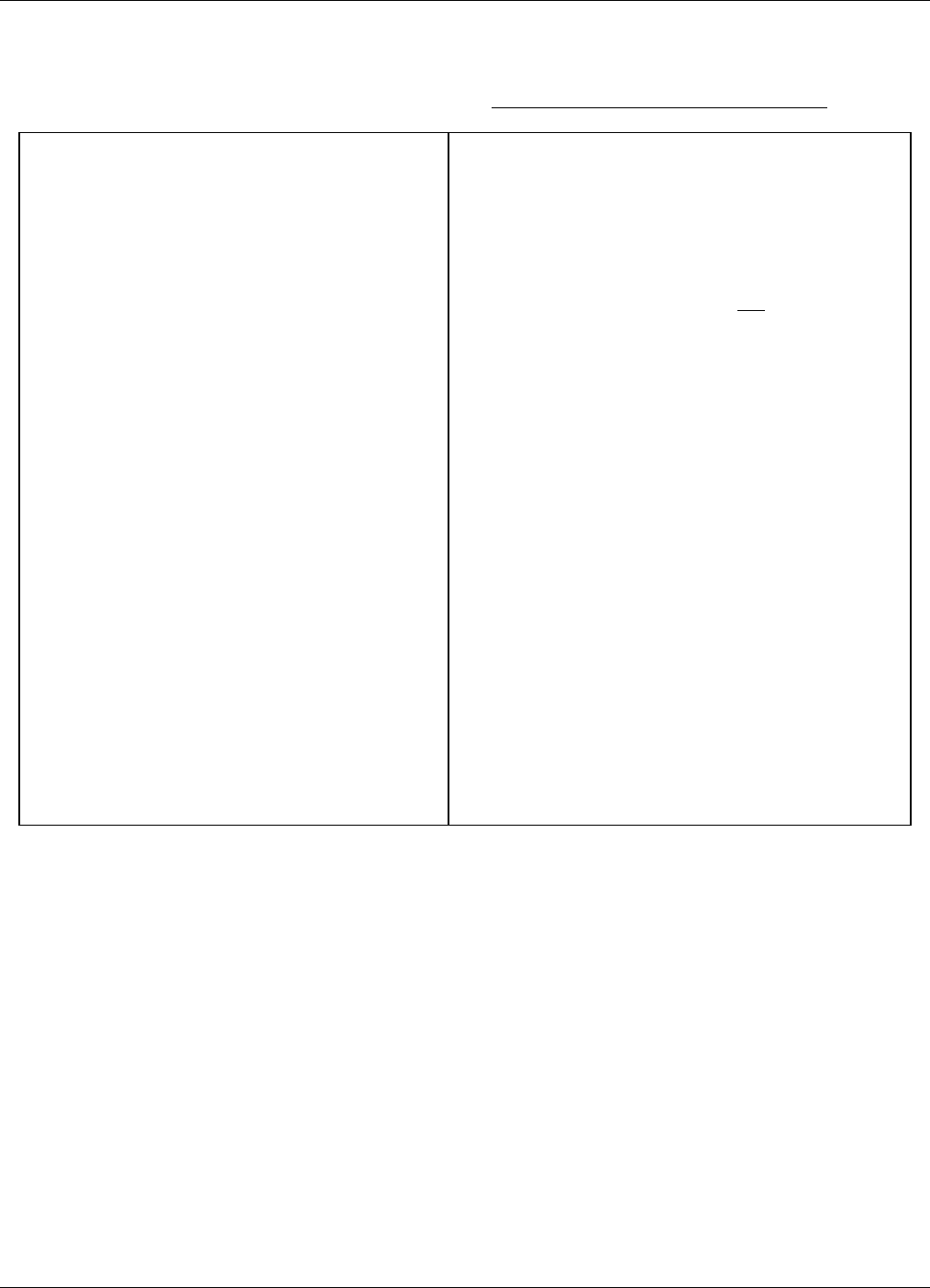

Table 7-4. Definition of Level 1 and Level 2 Zero and Span Checks

(from Section 2.0.9 of Q.A. Handbook for Air Pollution Measurement Systems)

LEVEL 1 ZERO AND SPAN CALIBRATION

A Level 1 zero and span calibration is a

simplified, two-point analyzer calibration used

when analyzer linearity does not need to be

checked or verified. (Sometimes when no

adjustments are made to the analyzer, the Level

1 calibration may be called a zero/span check, in

which case it must not be confused with a Level 2

zero/span check.) Since most analyzers have a

reliably linear or near-linear output response with

concentration, they can be adequately calibrated

with only two concentration standards (two-point

concentration). Furthermore, one of the

standards may be zero concentration, which is

relatively easily obtained and need not be

certified. Hence, only one certified concentration

standard is needed for the two-point (Level 1)

zero and span calibration. Although lacking the

advantages of the multipoint calibration, the two-

point zero and span calibration--because of its

simplicity--can be (and should be) carried out

much more frequently. Also, two-point

calibrations are easily automated. Frequency

checks or updating of the calibration relationship

with a two-point zero and span calibration

improves the quality of the monitoring data by

helping to keep the calibration relationship more

closely matched to any changes (drifts) in the

analyzer response.

LEVEL 2 ZERO AND SPAN CHECK

A Level 2 zero and span check is an "unofficial" check

of an analyzer's response. It may include dynamic

checks made with uncertified test concentrations,

artificial stimulation of the analyzer's detector,

electronic or other types of checks of a portion of the

analyzer, etc.

Level 2 zero and span checks are not

to be used as a

basis for analyzer zero or span adjustments,

calibration updates, or adjustment of ambient data.

They are intended as quick, convenient checks to be

used between zero and span calibrations to check for

possible analyzer malfunction or calibration drift.

Whenever a Level 2 zero or span check indicates a

possible calibration problem, a Level 1 zero and span

(or multipoint) calibration should be carried out

before any corrective action is taken.

If a Level 2 zero and span check is to be used in the

quality control program, a "reference response" for

the check should be obtained immediately following a

zero and span (or multipoint) calibration while the

analyzer's calibration is accurately known.

Subsequent Level 2 check responses should then be

compared to the most recent reference response to

determine if a change in response has occurred. For

automatic Level 2 zero and span checks, the first

scheduled check following the calibration should be

used for the reference response. It should be kept in

mind that any Level 2 check that involves only part of

the analyzer's system cannot provide information

about the portions of the system not checked and

therefore cannot be used as a verification of the

overall analyzer calibration.

07266B DCN6485