4/00 UDC 3300 Process Controller Product Manual 229

7.5 Input #1, #2, or #3 Calibration Procedure

Introduction

Apply power and allow the controller to warm up for 15 minutes before

you calibrate. Read “Set Up Wiring” before beginning the procedure.

Make sure you have LOCKOUT set to NONE. See Section 3 –

Configuration.

CAUTION

For linear inputs, avoid step changes in inputs. Vary smoothly

from initial value to final 100 % value.

Procedure

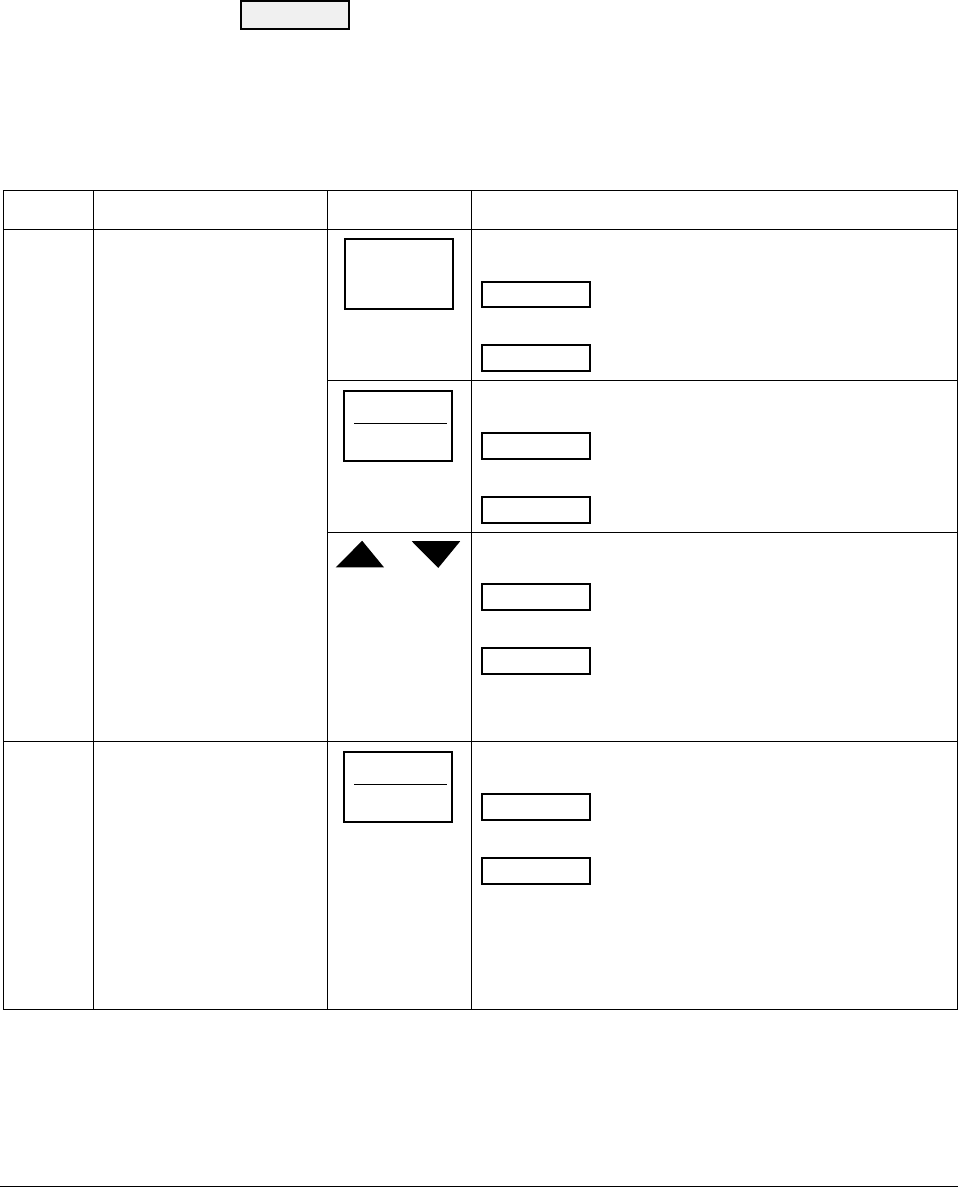

The Calibration procedure for Input #1, #2, or #3 is listed in Table 7-5.

Table 7-5 Input #1, #2, or #3 Calibration Procedure

Step Description Press Action

1

Enter Calibration Mode

SET UP

until you see

INPUT n

Lower Display

CALIB

Upper Display

n = 1, 2, or 3

FUNCTION

LOOP 1/2

You will see:

CAL IN n

Lower Display

DISABL

Upper Display

n = 1, 2, or 3

or

The calibration sequence is enabled and you will see:

CAL IN n

Lower Display

BEGIN

Upper Display

n = 1, 2, or 3

At the completion of the sequence, the selection

automatically reverts to disable.

2

Calibrate 0 %

FUNCTION

LOOP 1/2

You will see:

INn ZERO

Lower Display

APPLY

Upper Display

n = 1, 2, or 3

Adjust your calibration device to an output signal equal to

the 0 % range value for your particular input sensor. See

Table 7-1 for Voltage or Resistance equivalents.

Wait 15 seconds, then go to the next step.